5. PARAMETERS

5 - 101

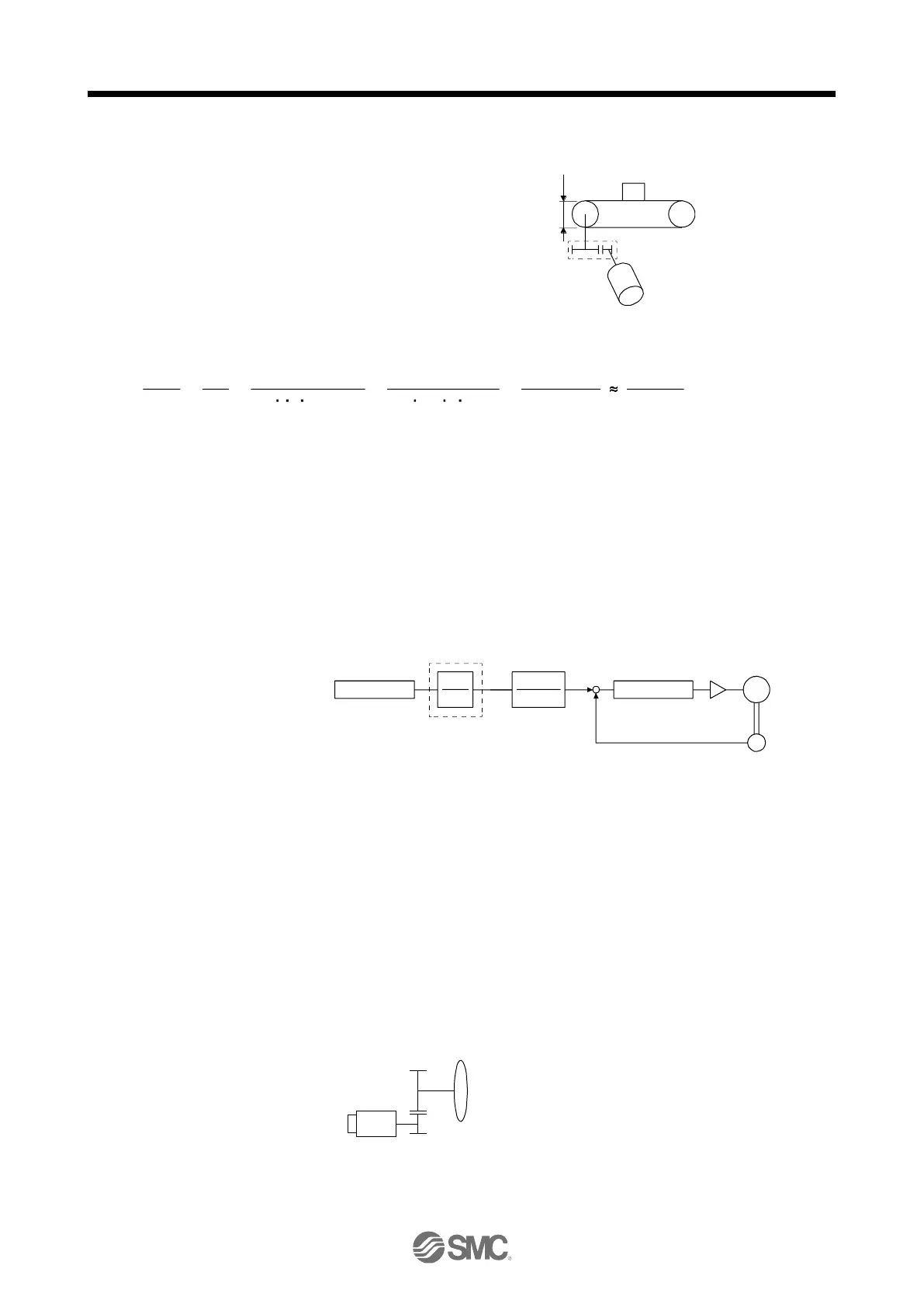

(b) Setting example of a conveyor

Machine specifications

Pulley diameter: r = 160 [mm]

Reduction ratio: 1/n = Z

1

/Z

2

= 1/3

Z

1

: Number of gear teeth on servo motor side

Z

2

: Number of gear teeth on load gear

Servo motor encoder resolution

4194304 [pulse/rev]

Z1Z2

1/n = Z1/Z2 = 1/3

1/n

r = 160 [mm]

Servo motor encoder resolution P

t

= 4194304 [pulse/rev]

CMX

CDV

P

t

=

ΔS

P

t

=

4194304

=

4194304

=

167551.61

524288

209441/n r πα (Note) 1/3 160 π 1000

Because the command unit is "mm", α is 1000. When the unit is "inch", α is 10000. When the unit is "pulse", α is 1.

Reduce CMX and CDV to within the setting range or lower and round off each value to the closest

whole number.

Therefore, set CMX = 524288 and CDV = 20944.

(2) Setting [degree] with "Position data unit" of [Pr. PT01].

Set the number of gear teeth on machine side to [Pr. PA06] and the number of gear teeth on servo motor

side to [Pr. PA07].

Travel distance

Deviation counter

+

-

Electronic gear

([Pr. PA06]/[Pr. PA07])

Servo motor

Encoder

M

P

t

: Servo motor encoder resolution: 4194304 [pulse/rev]

CDV

CMX

360000

P

t

Set the electronic gear within the following range. Setting out of the range will trigger [AL. 37 Parameter

error].

(a) Set values to make numerator and denominator 16384 or lower if the electronic gear (CMX/CDV) is

reduced to its lowest terms.

(b) Set values to make numerator and denominator 16777216 or lower if (CMX × P

t

)/(CDV × 360000) is

reduced to its lowest terms.

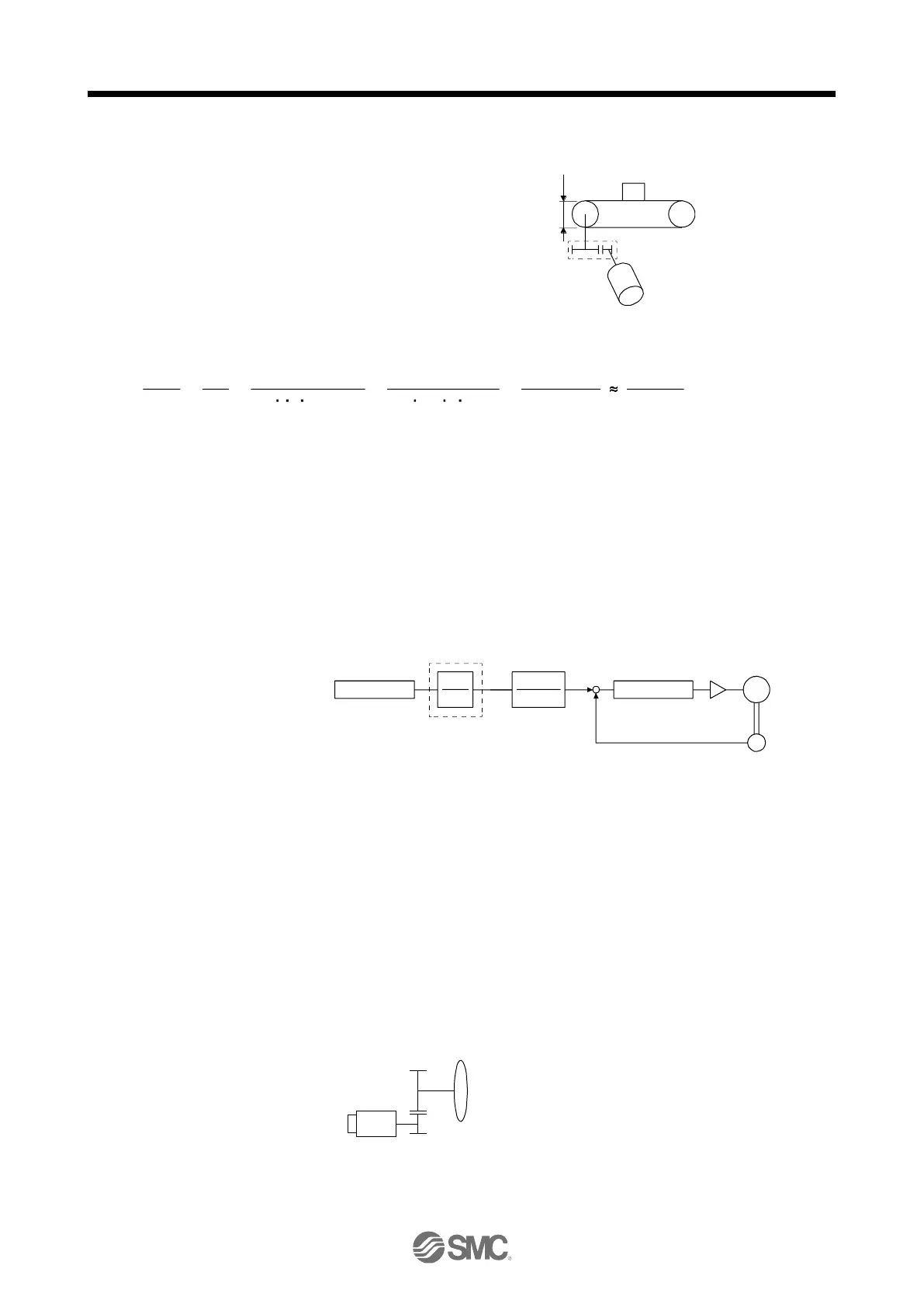

The following shows a setting example of the electronic gear.

Number of gear teeth on machine side: 25, number of gear teeth on servo motor side: 11

Set [Pr. PA06] = 25 and [Pr. PA07] = 11.

P

t

(Servo motor resolution): 4194304 pulses/rev

Z1: Number of gear teeth on servo motor side

Z2: Number of gear teeth on machine side

Z1: Z2 = 11:25

Servo motor

Machine

Z2

Z1

Loading...

Loading...