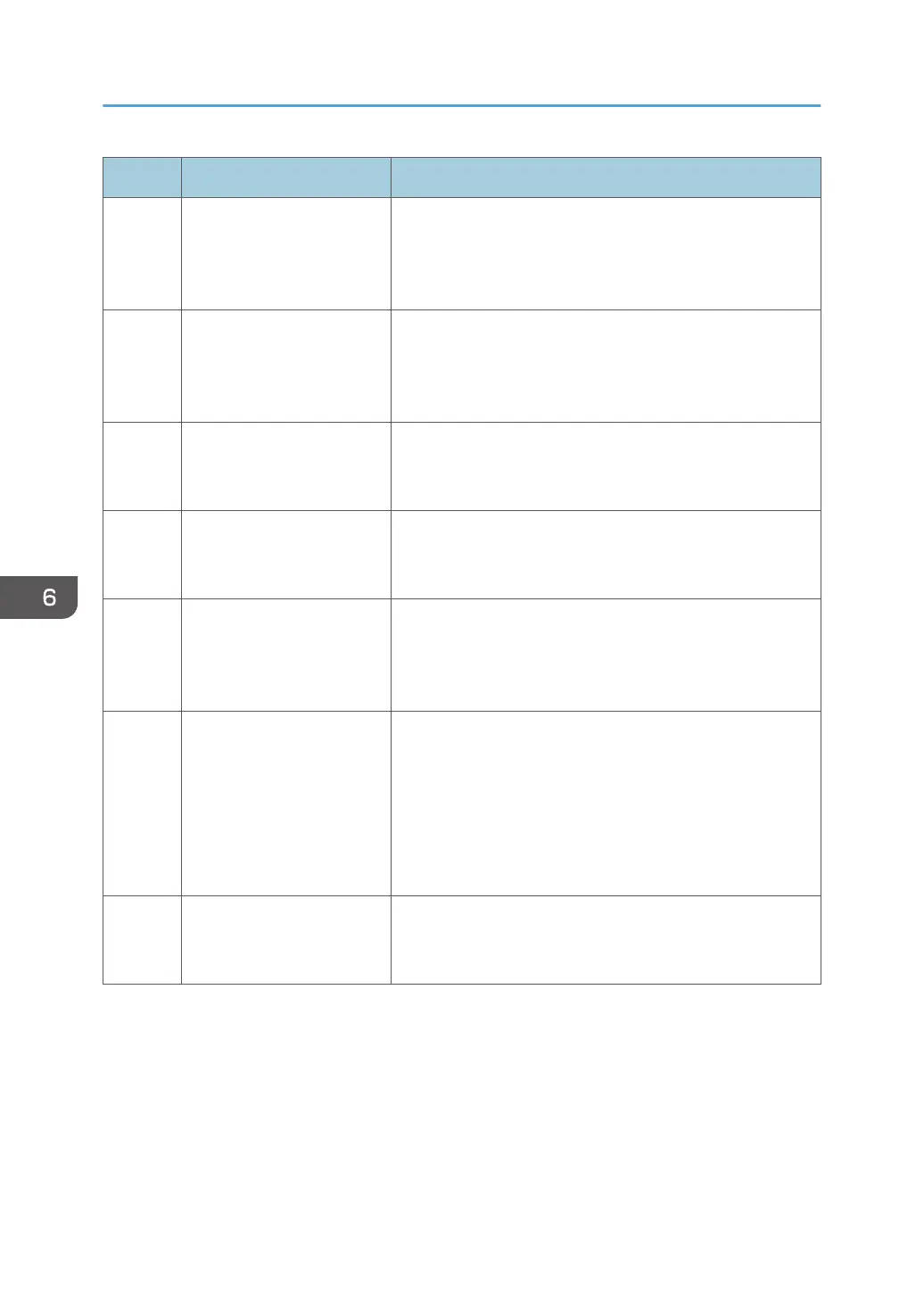

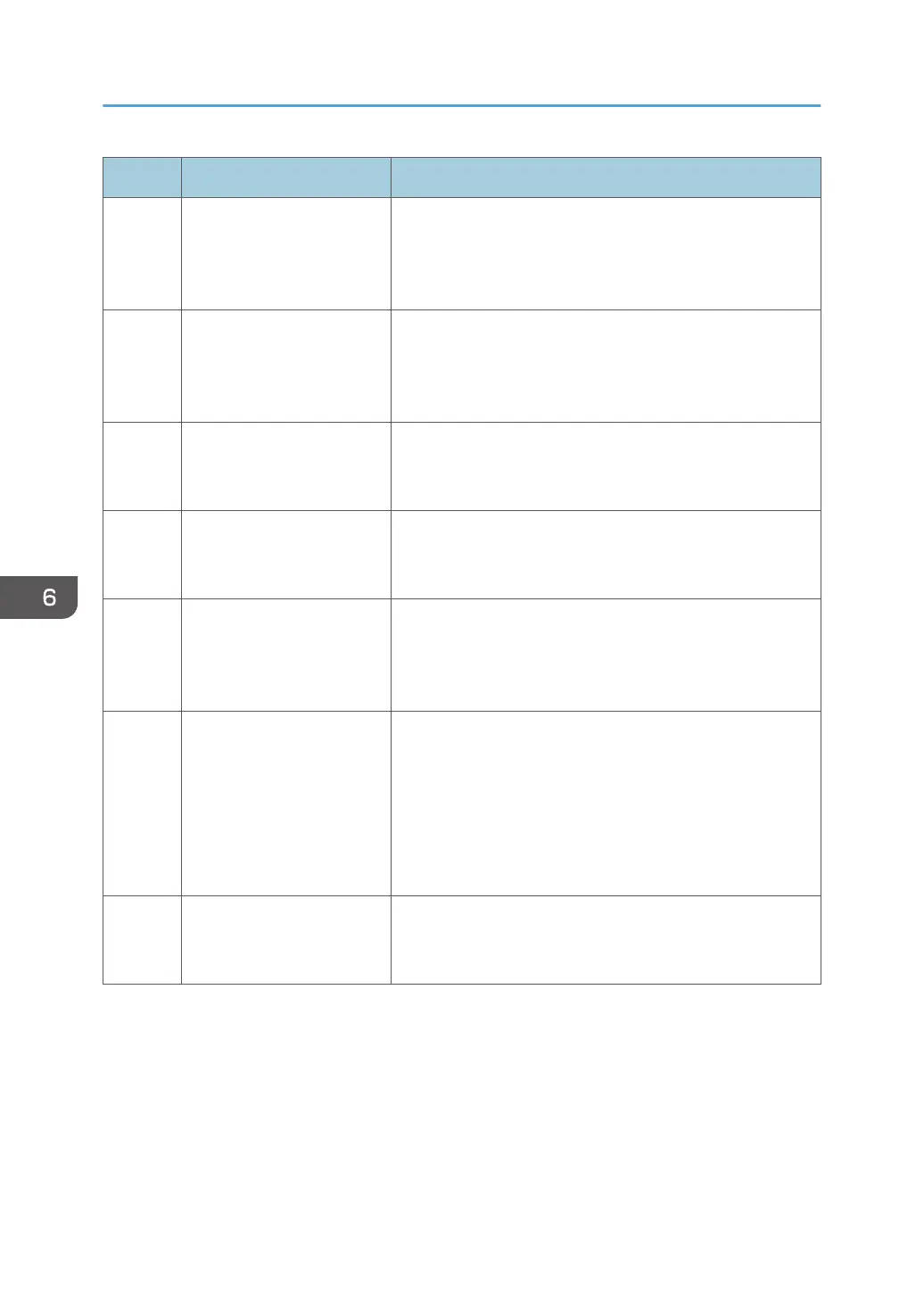

No. Component Function

1 Suction Cap Sensor This sensor switches the maintenance motor on and off

when the motor raises and lowers the K1 cradle for capping

during the printing cycle or during the print head cleaning

cycle.

2 Maintenance Motor The maintenance motor: 1) Raises and lowers the print head

suction cap, 2) Drives the pump that sucks waste ink from

the print heads through the suction cap, and 3) Drives the

wiper blade and wiper in the cleaning unit.

3 Maintenance Lift Sensor Controls the operation of the maintenance lift motor that

raises and lowers the color cradle (K2, C, YM) during

capping.

4 Slide Sensor This sensor controls the operation of the maintenance motor

when it slides the K1 cradle to the front (home position) or to

the rear during the print head cleaning cycle.

5 Maintenance Lift Motor Raises and lowers the color cradle (K2, C, YM caps) during

capping and the print head cleaning cycle. The

maintenance lift sensor controls operation of this motor

during raising and lowering.

6 BOW Board This is the ID chip holds the ID code that confirms the tank is

the correct one for the machine. The machine software

records a count in this chip every time the maintenance unit

suction cap operates to suck waste ink from the print heads

during cleaning. Once the count Is exceeded this signals

tank full, and the machine disables the code so that the tank

can no longer be used.

7 Ink Collector Cover Switch Detects when the ink collector tank door is opened and

closed. The machine does not operate until the cover is

closed.

6. Troubleshooting

756

Loading...

Loading...