No. Item

7 Sub scan motor

Here are the steps for loading paper in the bypass paper path:

1. When there is no paper in the paper path, the registration sensor detects OFF.

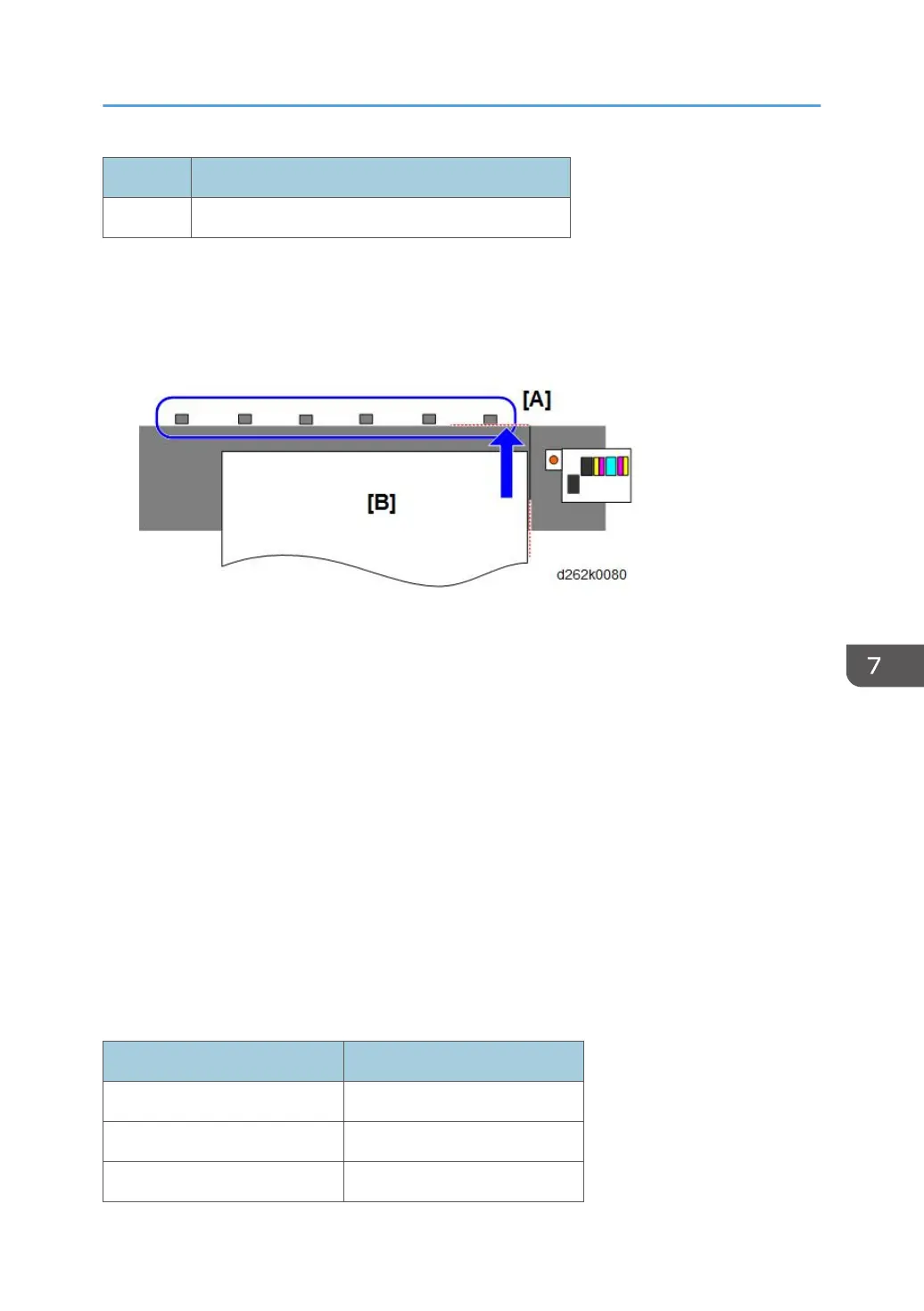

2. The operator puts the paper on the bypass tray. Insert the paper [B] as far as the stopper [A]

(registration sensor OFF, bypass sensor ON).

3. The operator closes the front cover and enters the settings for the paper on the operation panel.

The paper transport fan turns ON and the preparation for paper feed is start.

4. The carriage unit moves to the paper detect position and the DRESS sensor detects the paper. And

then, the carriadge unit moves to the air purging position.

5. The bypass stopper clutch turns ON and the vertical motor rotates in the reverse direction to the

position where the bypass stopper clutch sensor detects ON.

6. The bypass stopper clutch is turned OFF.

7. Skew detection is performed.

8. Paper width detection is performed.

9. The carriage unit moves to the paper leading edge detect position.

10. The vertical motor rotates in reverse to the paper length detect position (DRESS sensor OFF).

11. The carriage unit returns to the home position and the preparation for paper feed on the bypass

tray is finished.

Normally, the margin at the trailing edge is 18 mm, except when printing with color in the following

cases:

Media Print Mode

Special Standard

Special Quality

Matte Film Quality

Paper Feed and Exit

825

Loading...

Loading...