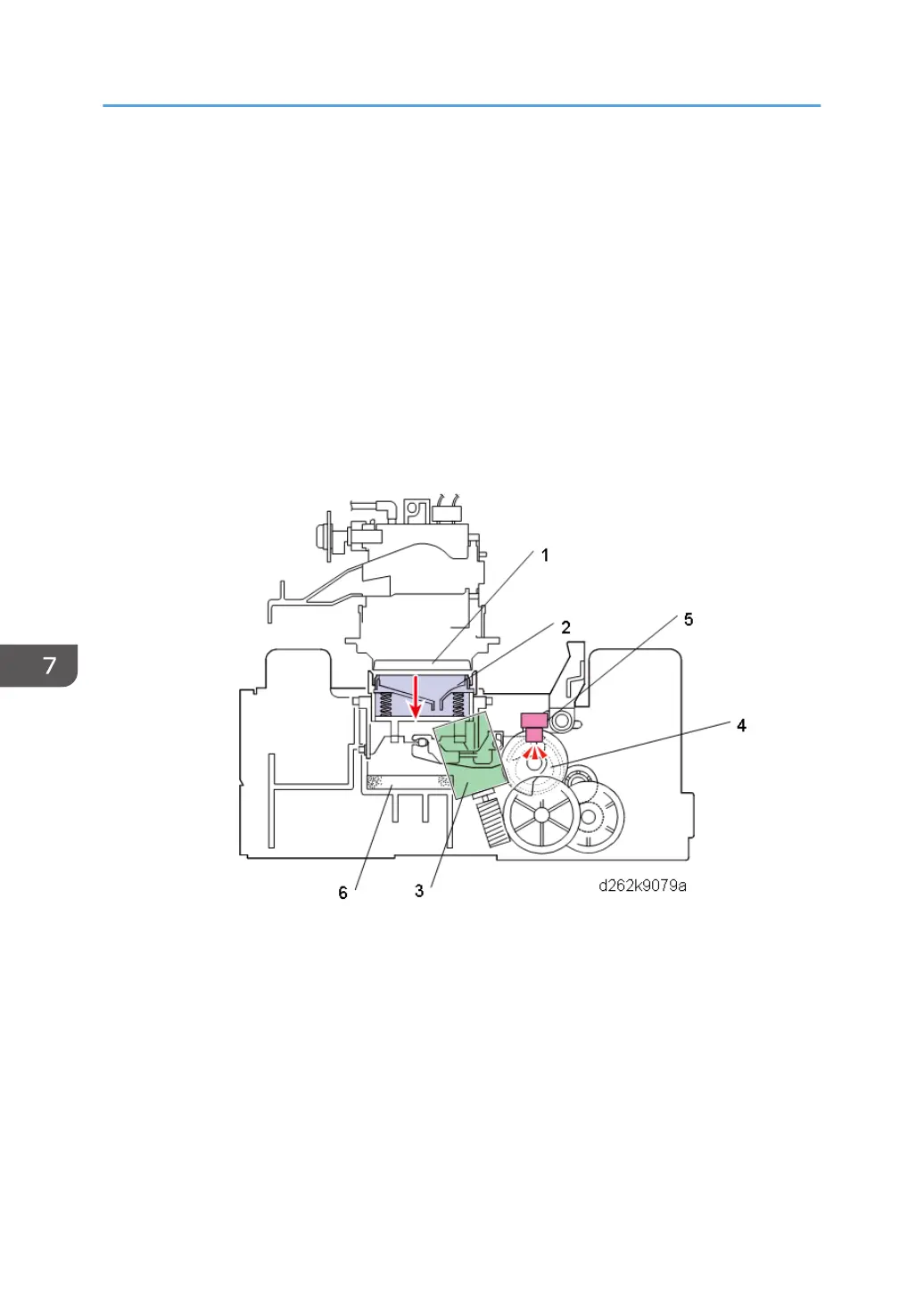

The maintenance motor uncaps and caps the K1 print head.

• While the machine is idle, the K1 print head (1) on the bottom of the carriage unit is capped and

sealed by the suction cap (2) to prevent it from drying out.

• At the start of the next job, the maintenance motor (3) rotates forward and lowers the suction cap to

uncap the K1 print head.

• At the end of the job, the carriage unit moves to the right and positions itself over the maintenance

unit.

• The maintenance motor rotates forward again and raises the suction cap to cap the K1 print head.

• The rotating suction cap actuator (4) (mounted on a shaft with a lift cam driven by the maintenance

motor) and suction cap sensor (5) control the raising and lowering of the suction cap.

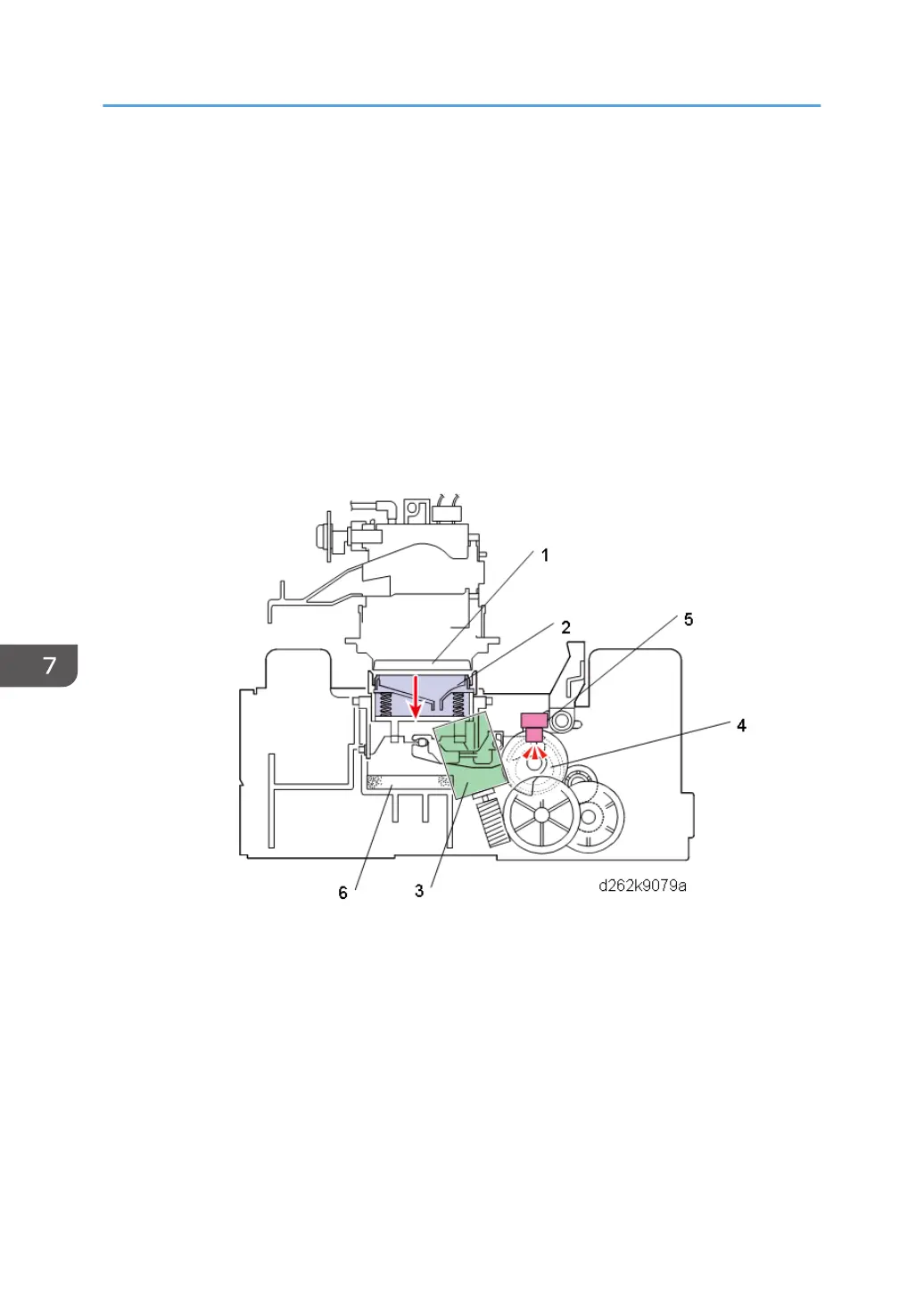

K2, Y1M1, C, Y2M2 Print Head Uncapping/Capping

• While the machine is idle, the K2, Y1M1, C, and Y2M2 print heads (1) on the bottom of the

carriage unit are capped and sealed by the print head caps (2).

• At the start of the next print job, the lift motor (3) rotates forward and lowers the K2, Y1M1, C, and

Y2M2 caps to uncap the K2, Y1M1, C, Y2M2 print heads.

• The rotating lift actuator (4) (mounted on a shaft with a cam driven by the lift motor) and lift sensor

(5) control the lowering of the four print caps.

• The caps rest on the absorbent cap pads (6) while they are down.

7. Detailed Description

856

Loading...

Loading...