20.PROFINET COMMUNICATION

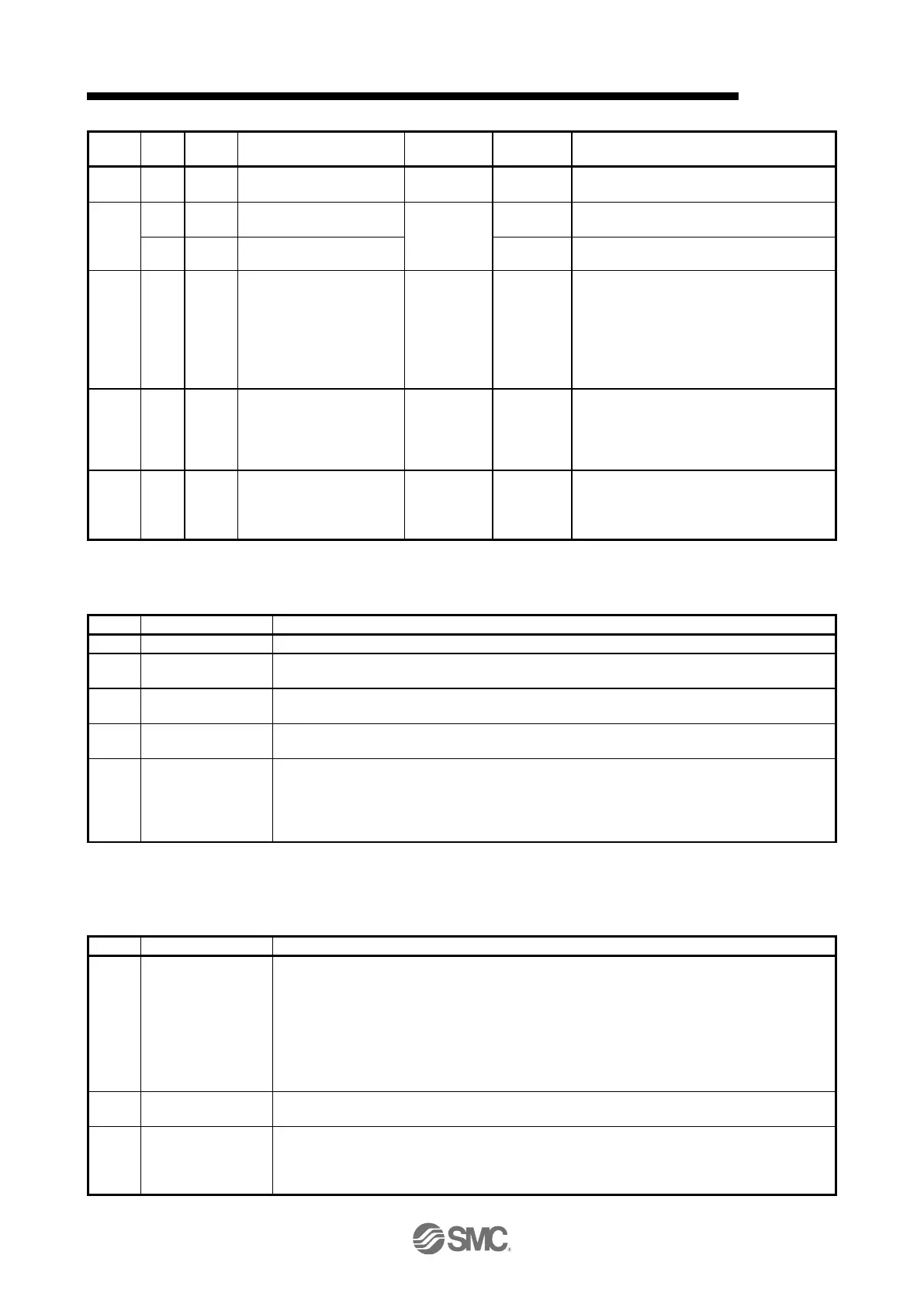

Negative torque limit value

Torque limit value (reverse)

Unit: 0.1% (rated torque of 100%)

Gear ratio: Number of revolutions of the servo

motor axis (numerator)

Gear ratio: Number of revolutions of the drive

axis (denominator)

Polarity selection

Bit 7: Position POL

Bit 6: Velocity POL

Bit 5: Torque POL

The values other than bit 5, 6, and 7 at

reading are undefined. Set "0" when writing.

Refer to section 8.5.

SI unit position

The value will be set automatically depending

on the value of [Pr. PT01] (_ x _ _) and [Pr.

PT03] (_ _ _ x). Refer to section 9.3.13 (5) for

details.

SI unit velocity

0.01 mm/s or 0.01 r/min

FB010300h (0.01 mm/s)

FEB44700h (0.01 r/min)

This is not supported by the _ driver.

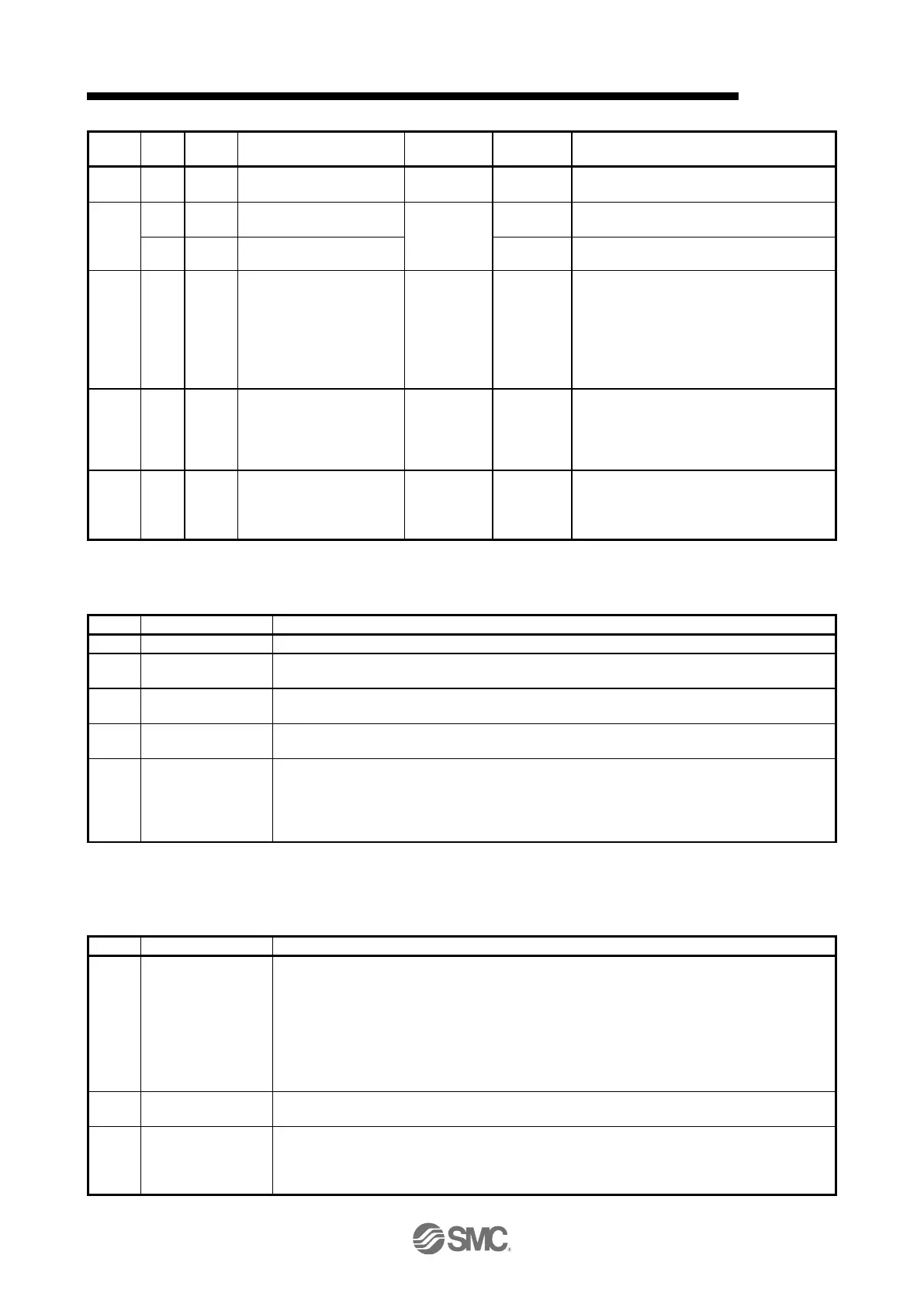

(2) Details on the OMS bit of Controlword (pp mode)

New positioning parameters are obtained when this bit turns on.

0: Set of set-points

1: Single set-point

0: Absolute position command

1: Relative position command (Note)

0: Positioning is executed.

1: The servo motor stops according to Halt option code (P24669).

Enabled only for Set of set-points (Bit 5 = 0).

0: The next positioning starts after the current positioning is completed (stopped) (black line (Refer

to (6) in this section.)).

1: The next positioning starts after positioning is executed with Profile velocity held up to the current

set-point (gray line (Refer to (6) in this section.)).

When the unit is set to degree, relative position commands are disabled. When the relative position command is specified and

positioning is started, [AL. F4.8] occurs and positioning cannot be started.

(3) Details on the OMS bit of Statusword (pp mode)

0 (Halt (Bit 8) = 0): Target position not reached.

0 (Halt (Bit 8) = 1): Axis decelerates

1 (Halt (Bit 8) = 0): Target position reached.

1 (Halt (Bit 8) = 1): Velocity of axis is 0

Judgment condition for Target position reached

If the error between Position actual value and Target position has stayed within Position window for

Position window time or more, Target position reached is stored.

0: Positioning completed (wait for next command)

1: Positioning being executed (The set-point can be overwritten.)

0: No following error

1: Following error

When the time set with Following error time out (P24678) has elapsed with the number of droop

pulses exceeding the set value of the Following error window (P24677), this bit becomes "1".

Loading...

Loading...