214733 390 Revision A

10. Raise windrower, remove stand, and lower windrower to ground.

11. Repeat Steps 2, page 389 to 8, page 389 for the other drive wheel.

12. Lower the windrower. Remove the jack. Refer to Lowering Drive Wheel, page 390.

13. Repeat torque procedure every hour of operation until two consecutive checks confirm that there is no movement of

the nuts.

Lowering Drive Wheel

This procedure is for lowering the drive wheel when it is raised on a jack stand. This procedure applies to both drive

wheels.

CAUTION

Jack stand must be capable of supporting a minimum of 2268 kg (5000 lb.).

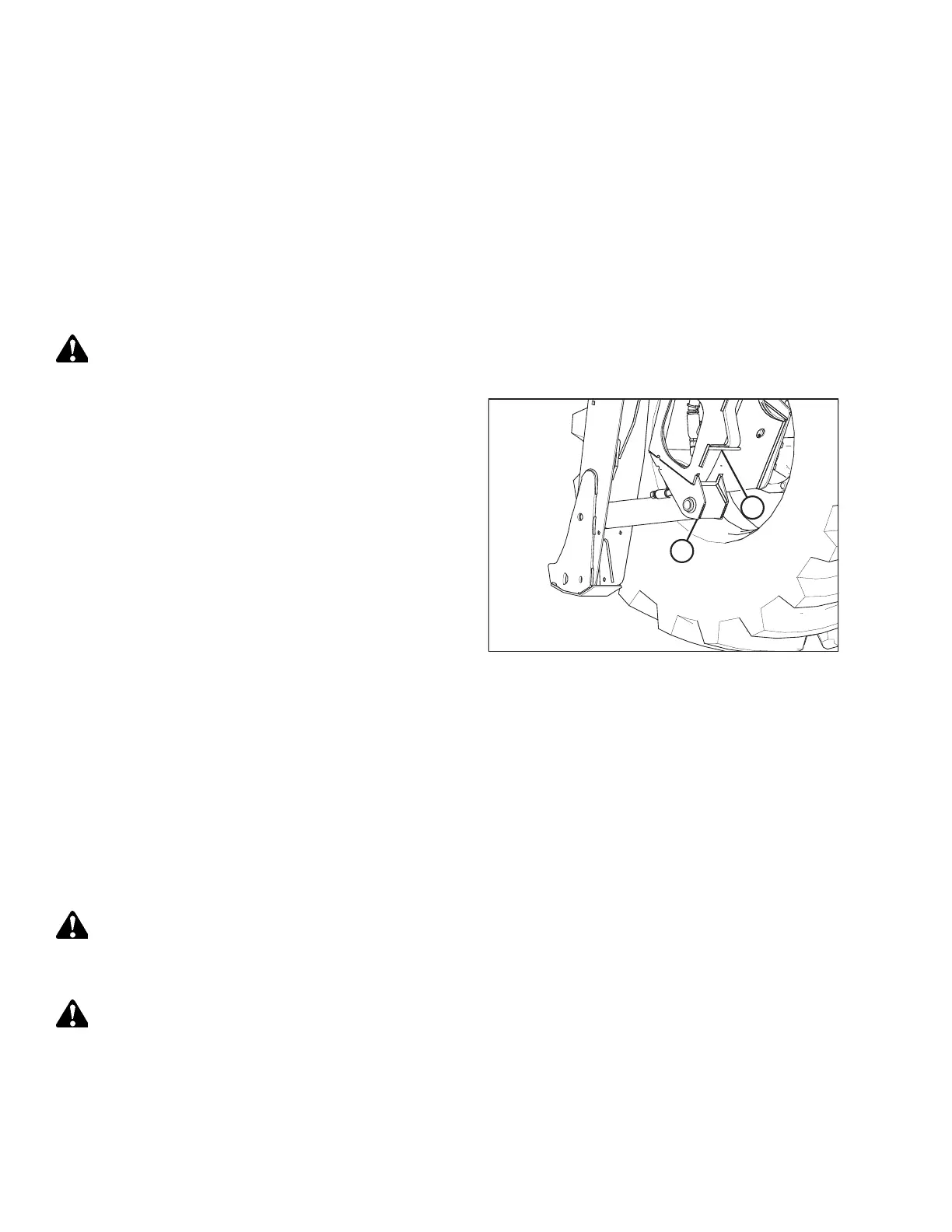

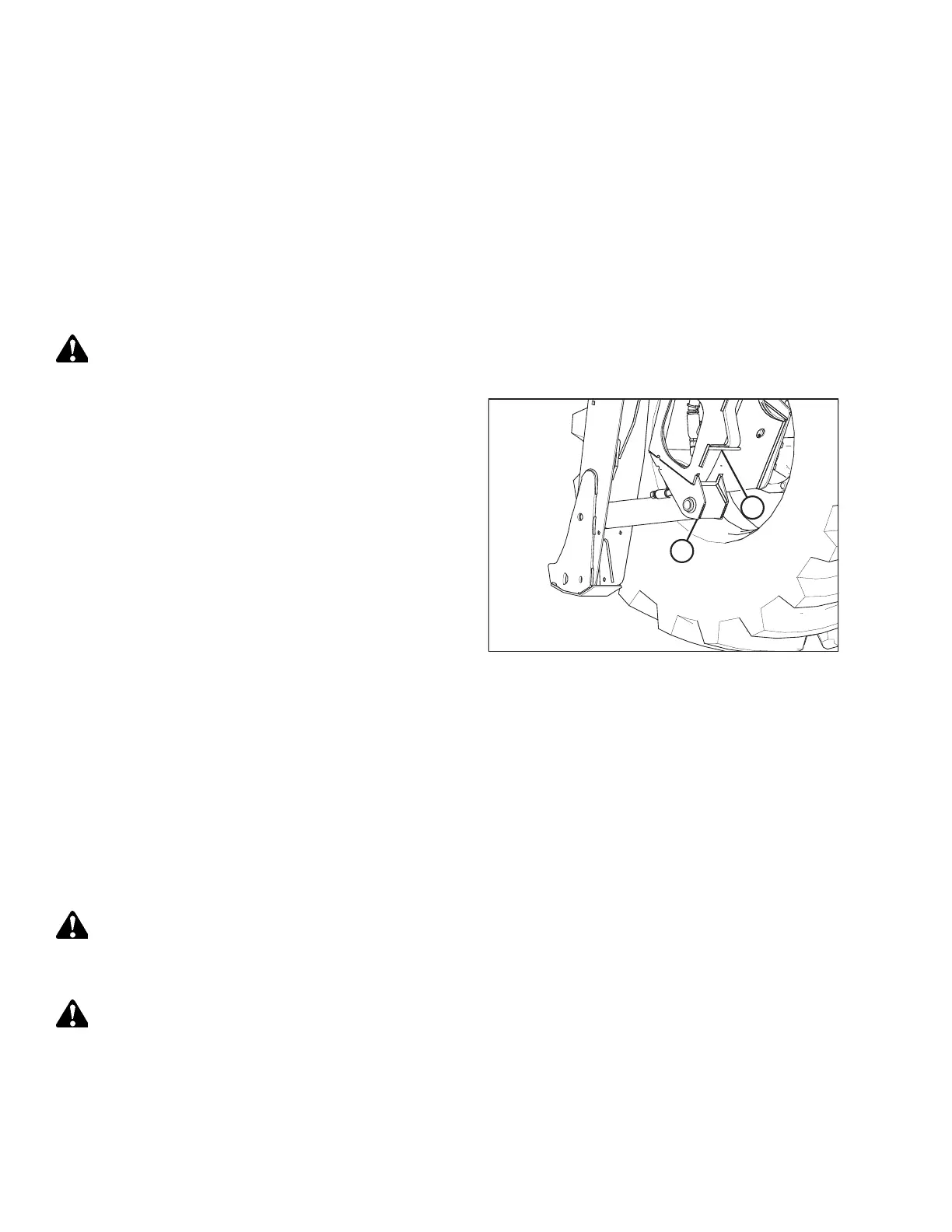

Figure 5.215: Drive Wheel Leg Jacking Point

1. Place a jack under the leg jack point (A), and raise the drive

wheel slightly off the jack stand.

2. Remove the jack stand from under the cylinder lift

mount (B). Lower the drive wheel to the ground.

3. Remove the jack.

5.15.9 Caster Wheels

Adjusting Caster Tread Width

The rear casters can be adjusted to a narrow tread width, which allows loading and shipping without having to

remove them.

A narrow tread width is better suited for smaller headers because it allows more space to the uncut crop, and provides

more maneuverability around poles, irrigation inlets, and other obstacles.

A wider tread width reduces runover in heavy crops that produce large windrows.

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

CAUTION

Park on a flat, level surface with the header on the ground, the ground speed lever in PARK position, and the steering

wheel in locked position (centered). Wait for the HPT to beep and display a red P symbol to confirm the park brakes

have engaged.

MAINTENANCE AND SERVICING

Loading...

Loading...