MAINTENANCE AND SERVICING

Adjusting Header Drop Rate

The header should lower gradually when the lower header switch is pressed. From fully raised to ground should

take approximately 3–4 seconds.

NOTE:

Drop rate should NOT be less than 3 t o 4 seconds as structural damage may result.

NOTE:

If drop rate is too slow (over 30 seconds), return to cut height or tilt or float presets will deactivate to prevent

overheating the hydraulic system.

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove

the key from the ignition before leaving the operator’s seat for any reason.

1. Lower header to grou

nd, stop the engine, and remove the key.

2. Open left cab-forw

ardsideplatform,referto5.3.1 Opening Platforms (Standard Position), page 309.

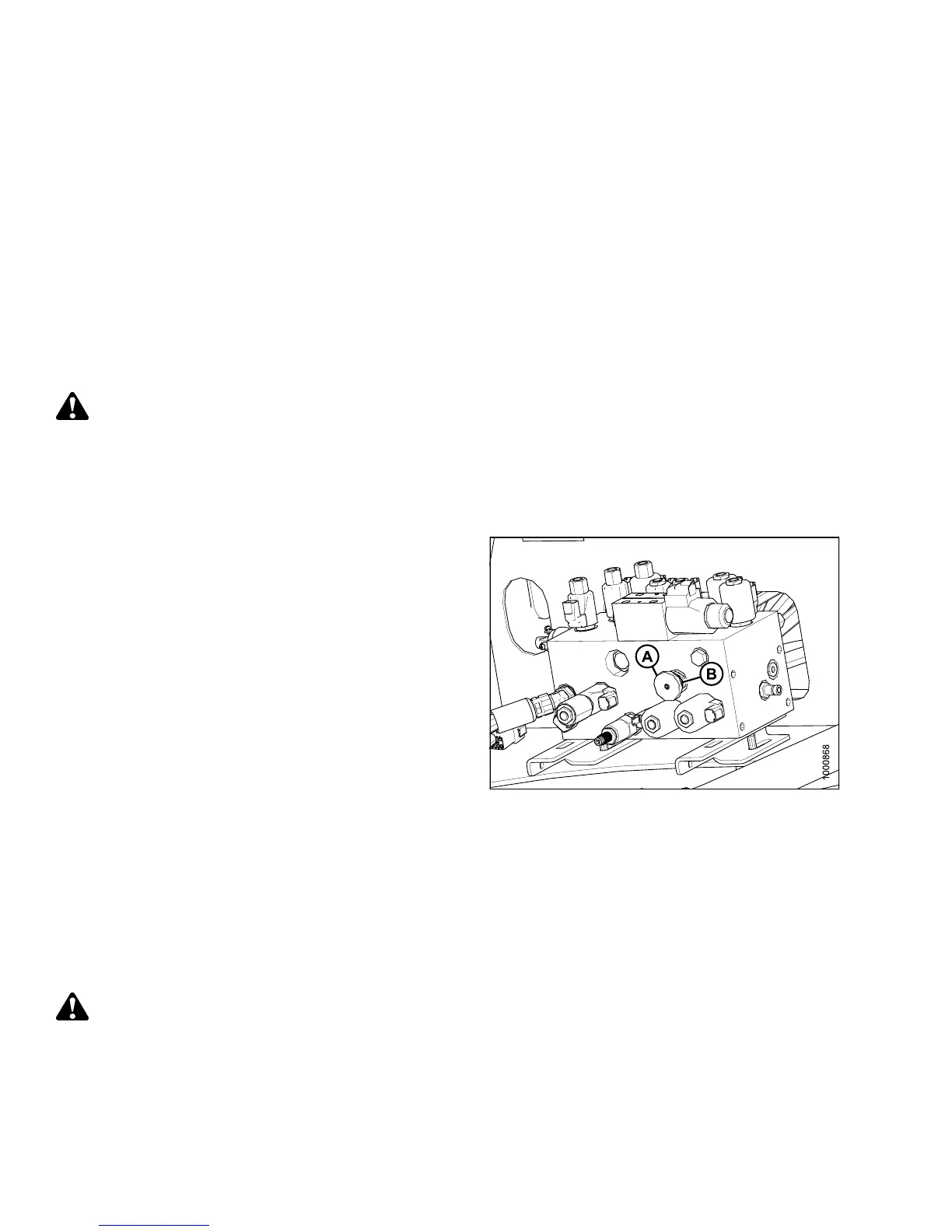

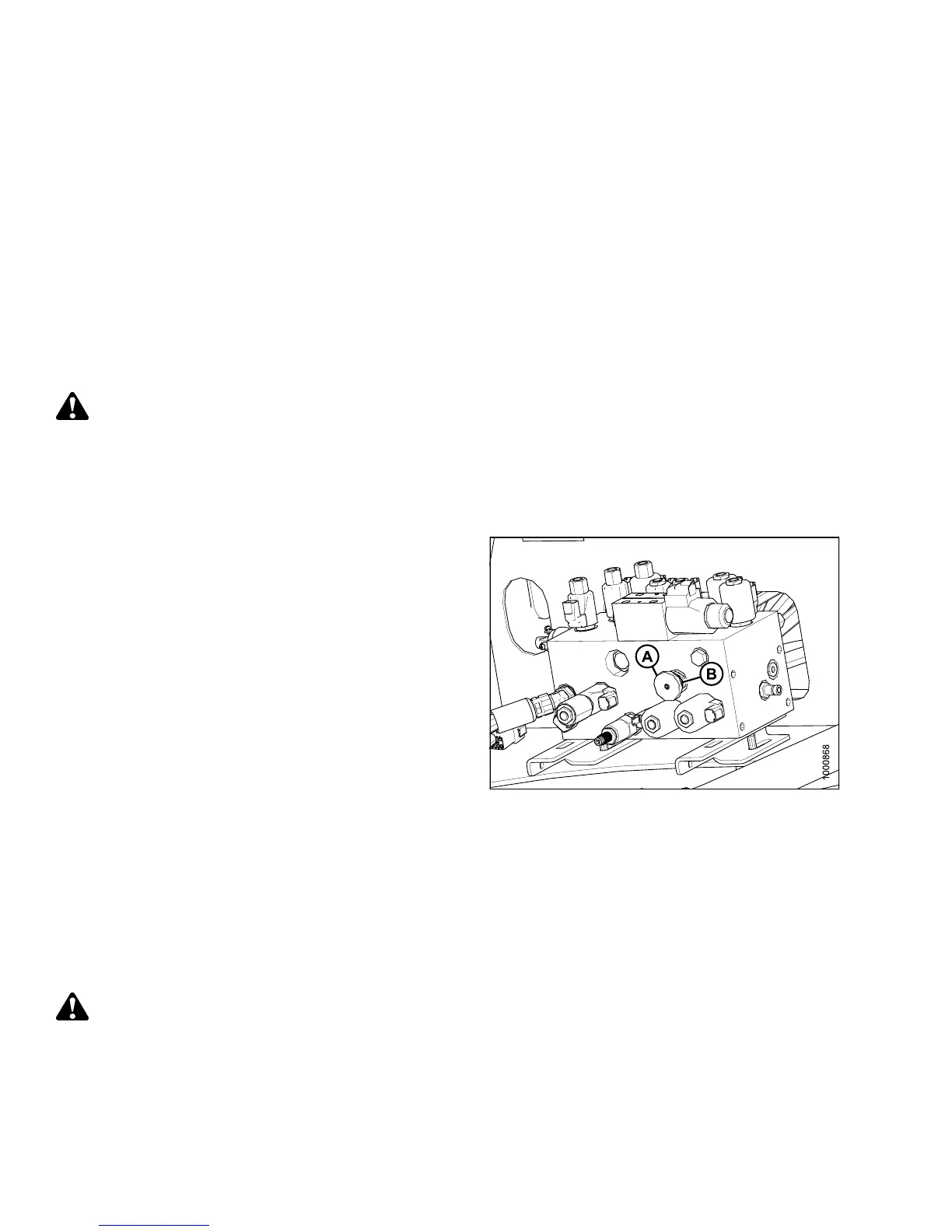

3. Loosen inne r knob (

B) on needle valve and then turn

outer knob (A):

• Clockwise to decre

ase the drop rate.

• Counterclockwis

e to increase the drop rate.

4. Tighten inner kno

b(A).

5. Check drop rate a

nd readjust as required.

6. Close the platfo

rm, refer to 5.3.2 Closing Platforms

(Standard Posit

ion), page 310.

Figure 5.196: Hydraul ic System

Adjusting Reel Drop Rate

The reel should lower gradually when the lower reel switch is pressed. From fully raised to fully lowered should

take approximately 3–4 seconds. Drop rate is a customer preference and will vary based on crop type and

cutting condition.

NOTE:

Drop speed sh

ould NOT be less tha n 3 to 4 seconds as structural dama ge may result.

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove

the key from the ignition before leaving the operator’s seat for any reason.

1. Lower header to ground, stop the engine, and remove the key.

147649 408 Revision A

Loading...

Loading...