MAINTENANCE AND SERVICING

IMPORTANT:

Recommended intervals are for average conditions. Service the machine more often if operated under adverse

conditions (severe dust, extra heavy loads, etc.).

CAUTION

Carefully follow safety messages given in 1 Safety, page 1.

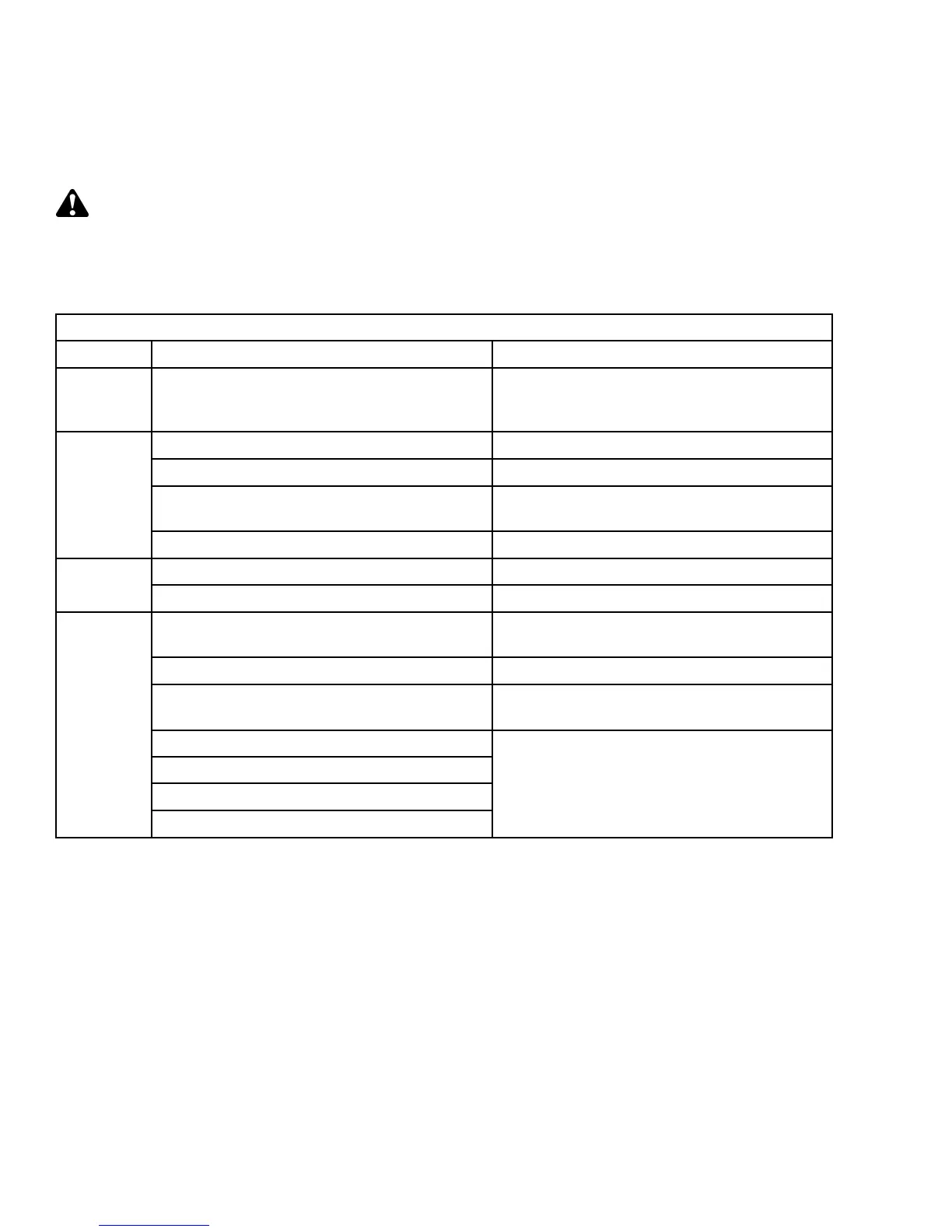

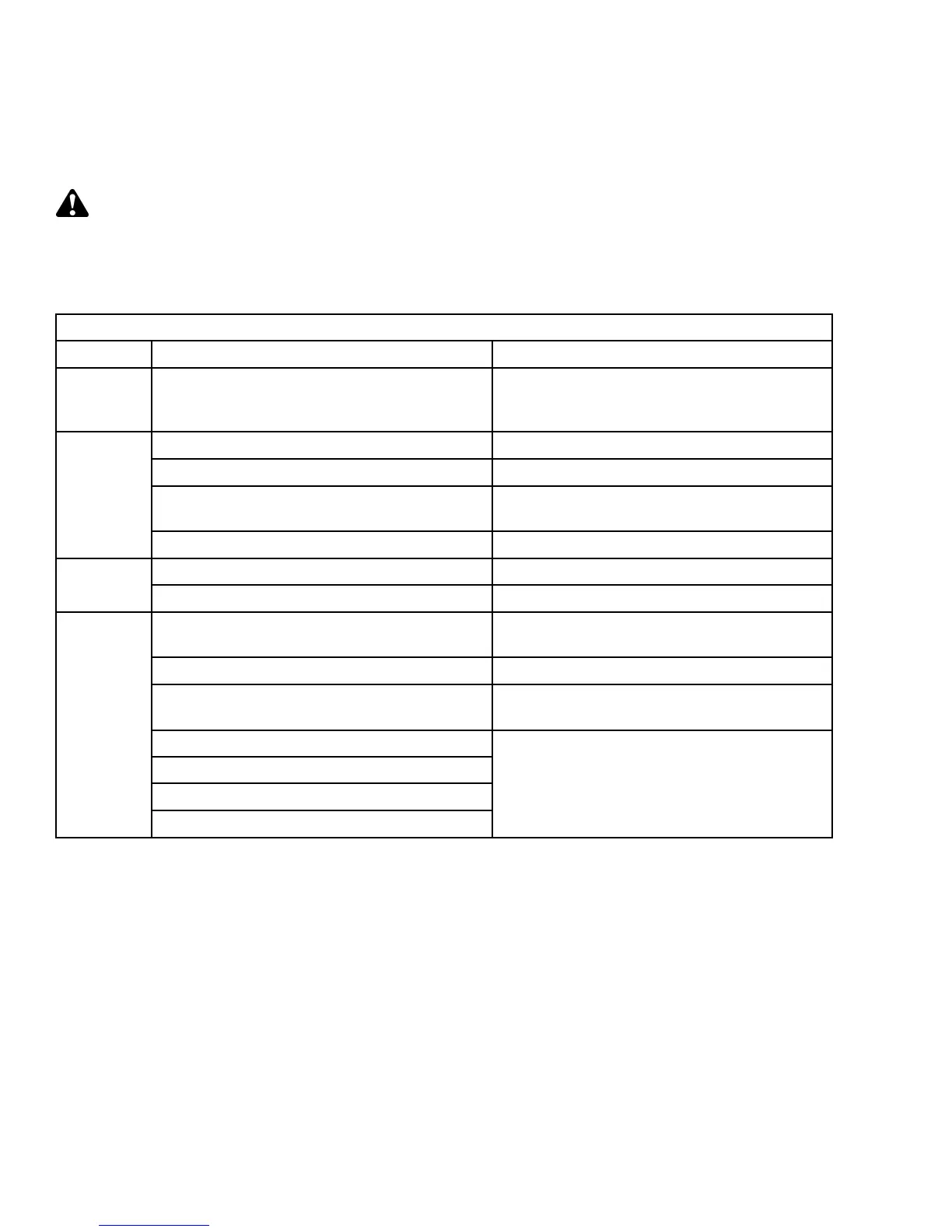

Break-In Inspections

Break-in Inspections

Hours Item

Check

1 Drive wheel n

uts

Torque: 375 ft·lbf (510 N·m) dry

Repeat checks at one hour intervals until

torque stabilizes at tw o consecutive checks

A/C compressor belt

Tens ion.

Caster wheel nuts Torque: 120 ft·lbf (163 N ·m)

Caster wheel anti-shimmy dampener bolts

Inboard bolt torque: 100 ft·lb f (135 N·m)

Outboard bolt torque: 85 ft·lbf (115 N·m)

5

Walking beam width adjustment bolts

Torq u e: 330 ft·lbf (448 N·m)

Walking beam width adjustment bolts

Torq u e: 330 ft·lbf (448 N·m)

10

Neutral Dealer-adju ste d

Hose clamps: air intake / radiator / heater /

hydraulic

Hand-tighten unless otherwise noted

Walkin

g beam width adjustment bolts

Torq u e: 330 ft·lbf (448 N·m)

Caster wheel anti-shimmy dampener bolts

Inboard bolt torque: 100 ft·lb f (135 N·m)

Outboard bolt torque: 85 ft·lbf (115 N·m)

Drive wheel lubricant

Main gearbox oil

Charge system oil filter

50

Manifold oil filter

Change

147649 426 Revision A

Loading...

Loading...