Installation and Commissioning

GARD 8000 SYS RFL Electronics

November 28, 2017 4-7 973.334.3100

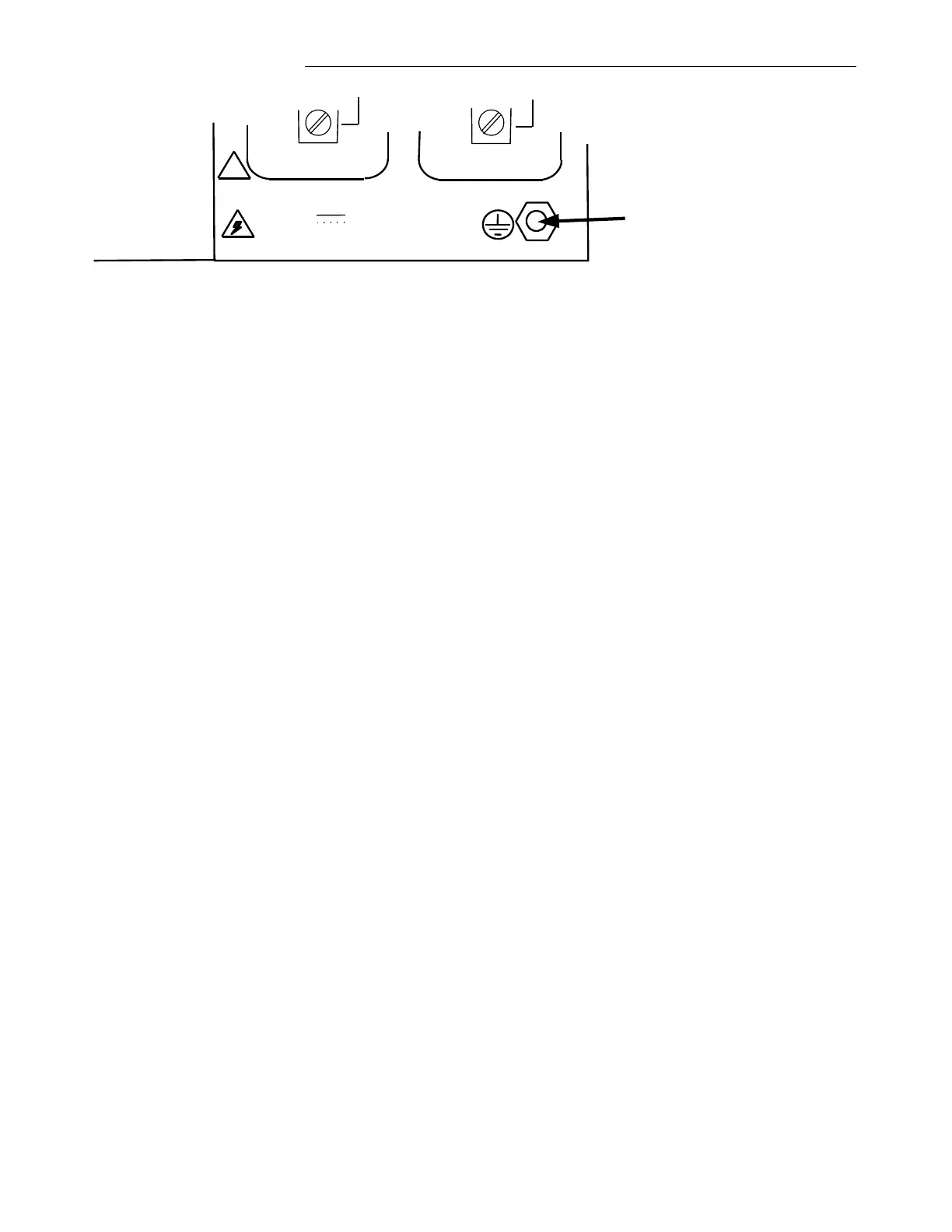

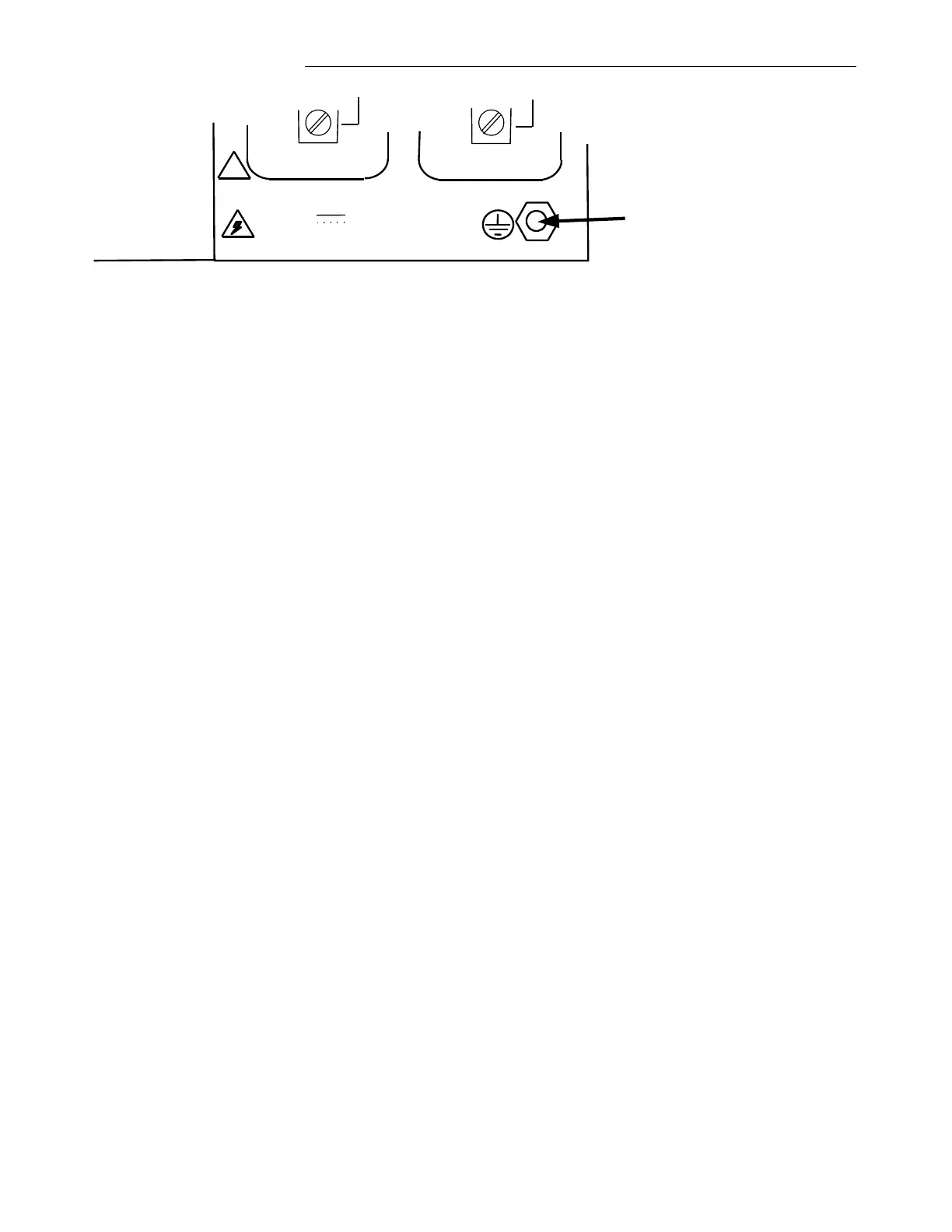

38-150/200-300 VDC

3 AMPS 220 W MAX.

!

MAJOR

MINOR

Protective Earth Stud

Figure 4-2. Location of Protective Earth Stud

Grounding is accomplished by connecting a wire 6AWG or larger between this protective earth stud

and rack ground. The grounding wire should be kept as short and straight as possible, to keep its

resistance and inductance to a minimum.

Before attempting to make power connections, make sure the GARD 8000 terminal is equipped with a

power supply designed to operate at the available input supply voltage. This can be determined by

checking the model designator on the module handle. If an external power supply is being used, check

the markings on the external power supply. If the wrong voltage is connected to the power supply,

component damage will result.

4.5.4 FIBER OPTIC CONNECTIONS

If your GARD 8000 is equipped with Fiber Optic Modules, fiber optic connectors must be connected

to the fiber optic heads on the rear panel of the GARD 8000. Type ST series bayonet fiber optic

connectors (or their equivalent) are used with both singlemode and multimode fibers. The exact mating

connector used will depend upon the head that is installed in the fiber optic module, and the specific

optic cable being used. When connecting fiber optic cables, make sure the connectors are properly

aligned before tightening and then fully tighten them. This will help minimize losses in the connector.

4.5.5 RS-449/X.21/V.35 DIGITAL INTERFACE CONNECTIONS

RS-449/X.21/V.35 digital interface connections are made to the GARD 8000 chassis via a 37-pin

connector located on the Power Supply I/O rear panel on both the 3U chassis and the 6U chassis. The

digital interface circuitry resides on the Display With TPS module and signals are routed from this

module to the Midplane. A cable harness assembly routes these signals from the Midplane to the 37-

pin connector on the rear panel of the Power Supply I/O module. The location of this connector is

shown in Figure 4-4. Wiring information for this connector is provided in Figure 4-5.

If additional RS-449/X.21/V.35 digital interface connections are needed they can be made available by

using the Comms I/O Base module with an RS-449/X.21/V.35 digital interface comms unit plugged

onto it. Each Comms I/O Base module can accommodate one additional RS-449/X.21/V.35 digital

interface comms unit.

The system typically comes pre-configured from the factory per customer specifications.

4.5.6 POWER LINE CARRIER CONNECTIONS

Loading...

Loading...