MAINTENANCE AND S ERVICING

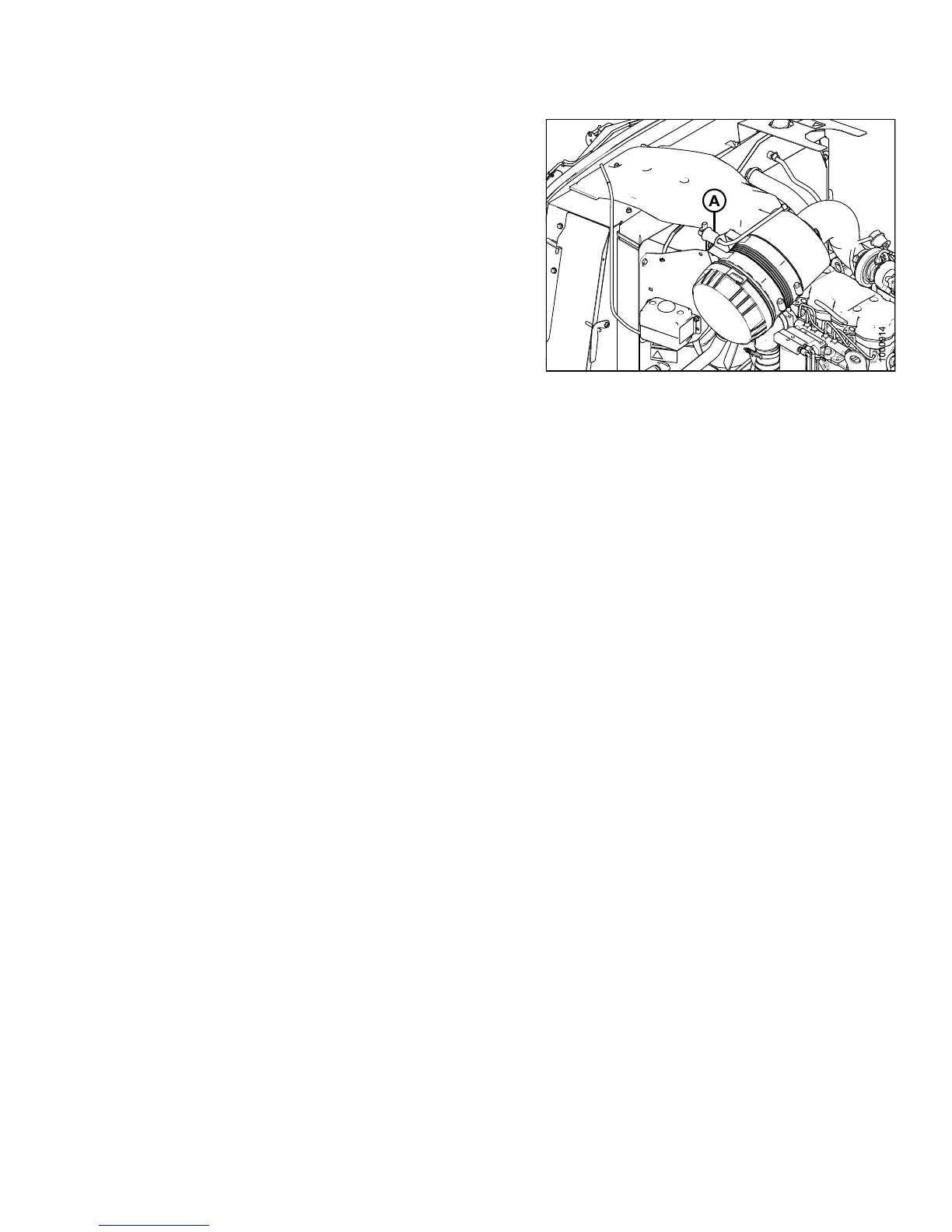

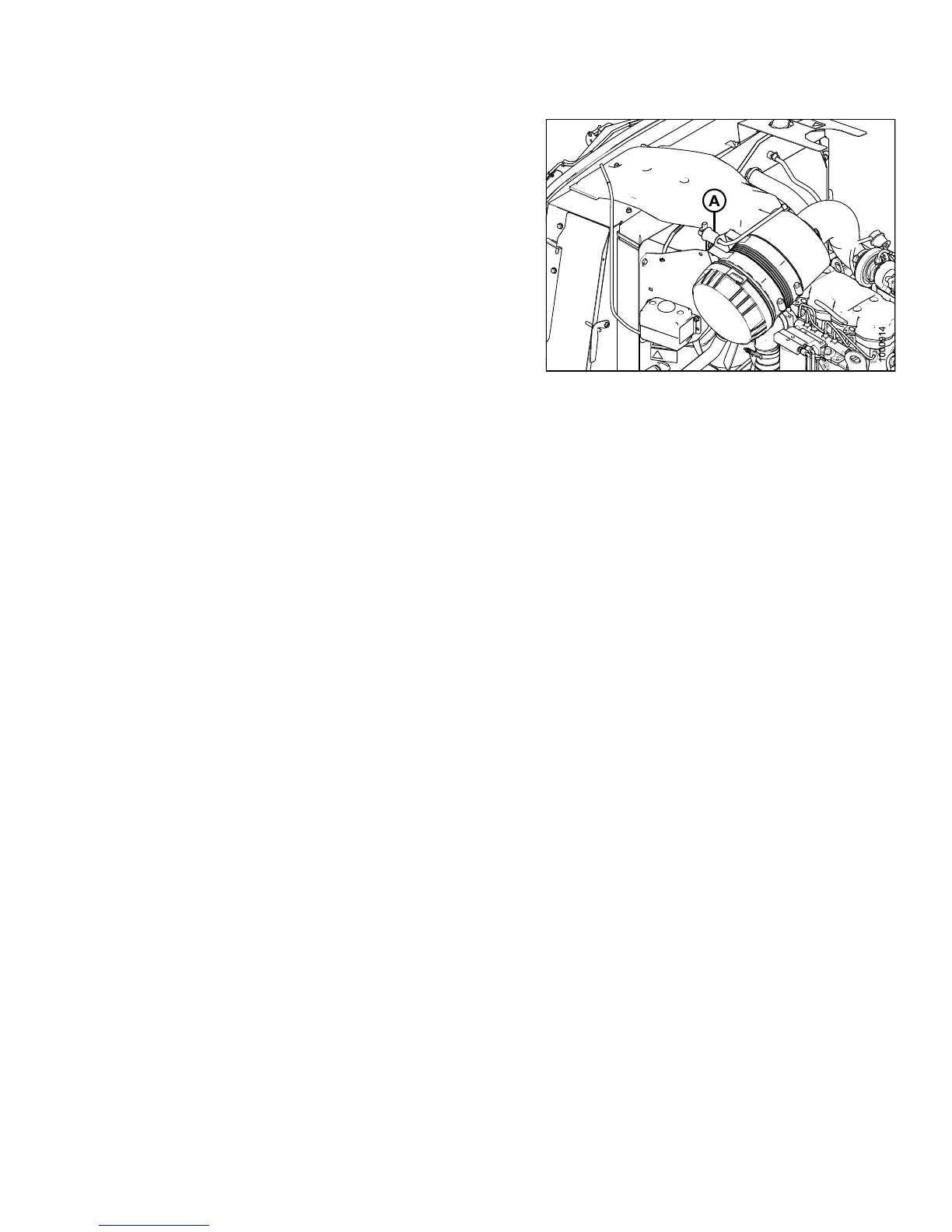

6. After servicing the filter, reset the restr iction switch (A)

by pushing the button on the end.

7. Close the hood, refer to 5.2.2 Clo sing Hood (Lower

Position), page 307.

8. Close the maintenance platform, refer to 5.3.1 Opening

Platforms (Standard Position), page 309.

Figure 5.69: Engine Air Cleaner

Cleaning Engine Air Filter Primary Element

IMPORTAN T

:

The second

ary (inner) element should NEVER be cleaned, only replaced.

IMPORTAN T:

Air filter element cleaning is NOT recommended due to the possible degradation of the element

material. If cleaning is performed, there are several risks involved and the following procedures should be

followed. If any of the following conditions are found, the filter element MUST be replaced.

1. Hold a bright light inside element, and check carefully for holes.

2. Check outer screen for dents. Vibration would quickly w ear a hole in the filter.

3. Check filter gasket for cracks, tears, or other signs of damage.

4. Check element for oil or soot contamination.

5. Check the secondary element for cleanliness. If there is visible dirt on the secondary element, replace both

primary and secondary elements. Do NOT clean.

IMPORTAN T:

The air cleaner’s primary (outer) filter element should be replaced after three cleanings or at the specified

interval. The secondary (inner) element should be replaced every third time the primary element is

changed. Refer to 5.5.11 Maintenance Schedule, page 425 for the required interval.

6. If secondary element passes inspection, clean primary element as follows:

a. Use compressed air NOT exceeding 60 psi (400 kPa), and a Dry Element Cleaner Gun.

b. Hold nozzle n ext to in ner surface only, and move up and down on pleats.

c. After three cleaning’s (or at the specified interval), replace the primary element.

7. Repeat inspection before ins ta lling .

147649 343 Revision A

Loading...

Loading...