MAINTENANCE AND SERVICING

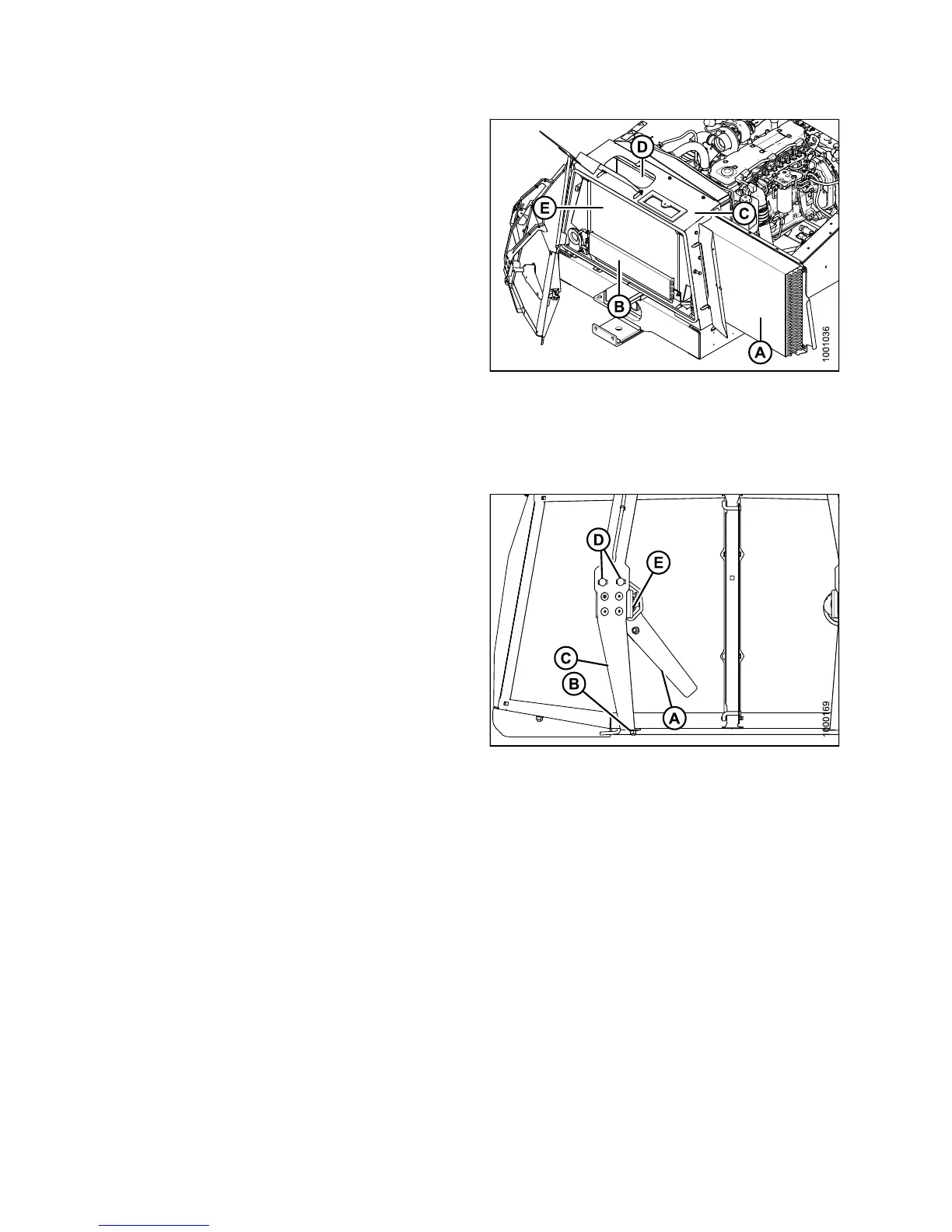

6. Clean radiator (D) through access holes in cooling box

with compressed air.

7. Clean oil cooler / air conditioning condenser (A),

charge air cooler (E), fuel cooler (B), and cooling

box (C) with compressed air.

8. Inspect all lines and coolers for evidence of leaks

and damage.

9. Slide oil cooler / air conditioning condenser (A) back

into cooling box (C).

10. Close side access door and lock with lever.

11. Close access door on top of the cooling box and secure

with wing nut.

12. Close cooler box screen, refer to Closing C ooler Box

Screen, page 363.

Figure 5.105: Engine Cooling System

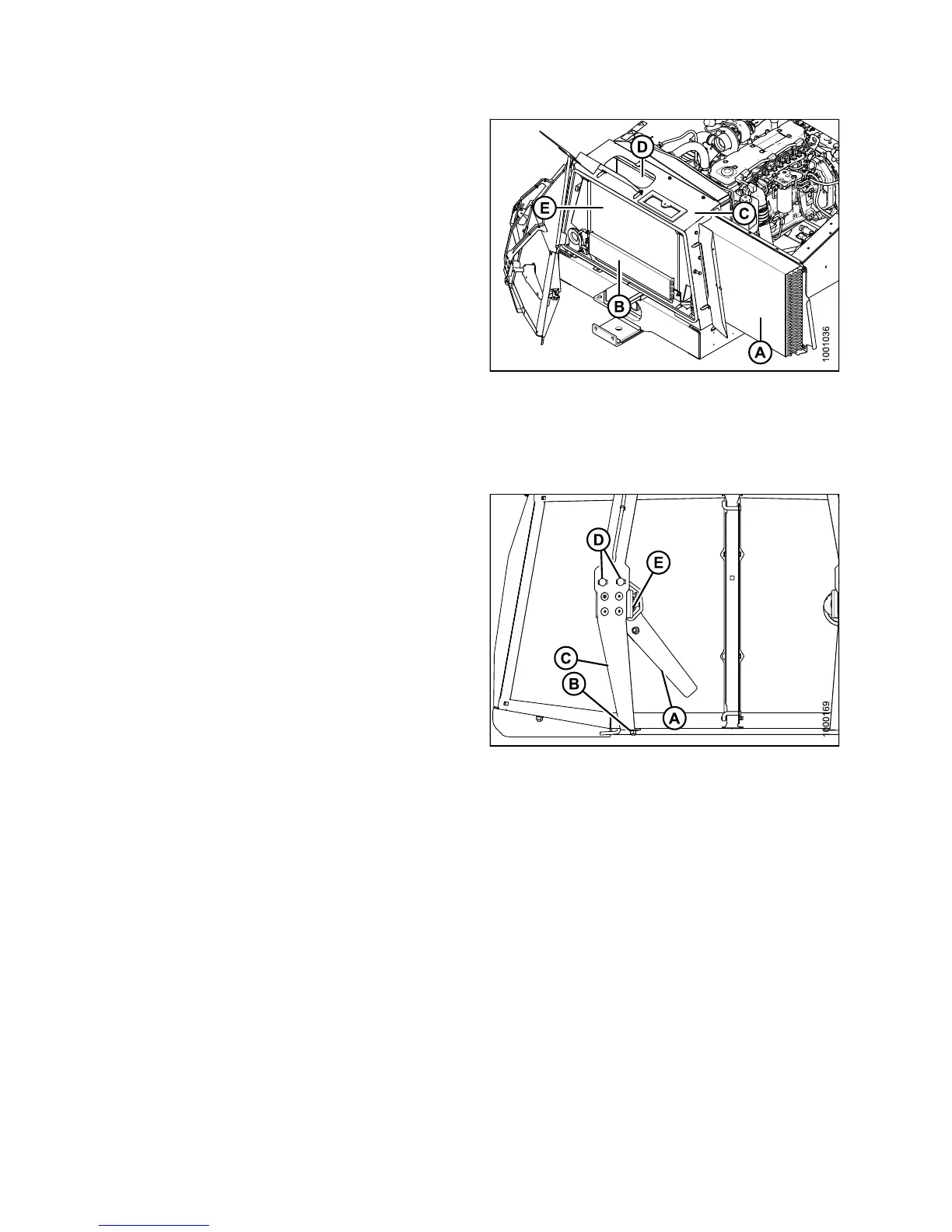

Adjusting Screen C

leaner Rotor to Screen Clearance

Check clearance b

etween trailing ed ge of s cre en cleaner

rotor (A) and s cre

en. It should be 3/64–5/16 in. (1–8 mm)

at all locations

when rotating.

NOTE:

Screen cleaner rotors rotate counterclockwise and may

touch screen as long as they continue to rotate.

If necessary, a

djust cle aran ce as f ollo ws:

1. Open the hood. R

efer to 5.2.1OpeningHood(Lower

Position), pag

e306.

2. Loosen nut (B)

on motor support (C).

3. Move support i

n or out until rotor is 3/32–1/4 in.

(2–6 mm) from s

creen nea r the cen ter.

4. Retighten nu

t(B).

5. Loosen the tw

o motor mount bolts (D).

6. Move motor/ r

otor assembly (E) to obtain 3/64–5/16 in.

(1–8 mm) gap

to screen a t full rot ation of the ro tor.

7. Retighten n

uts (D) on motor mount.

8. Close the ho

od. Refer to 5.2.2 Closing Hood (Lower

Position),

page 307.

Figure 5.106: Screen Cleaner

147649 362 Revision A

Loading...

Loading...