MAINTENANCE AND SERVICING

Adding Wheel Drive Lubricant

NOTE:

Do NOT mix lubricants of different brands or characteristics.

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove

the key from the ignition before leaving the operator’s seat for any reason.

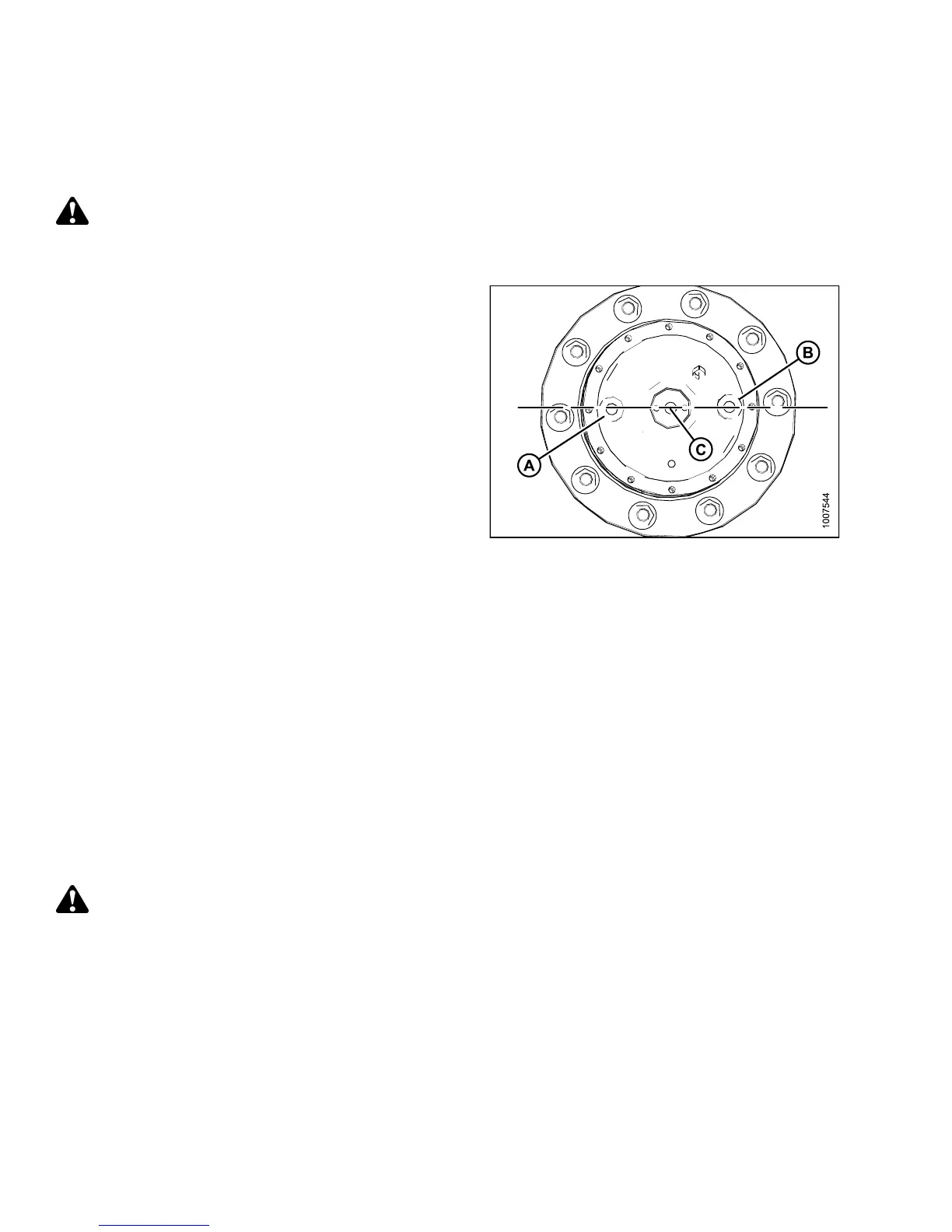

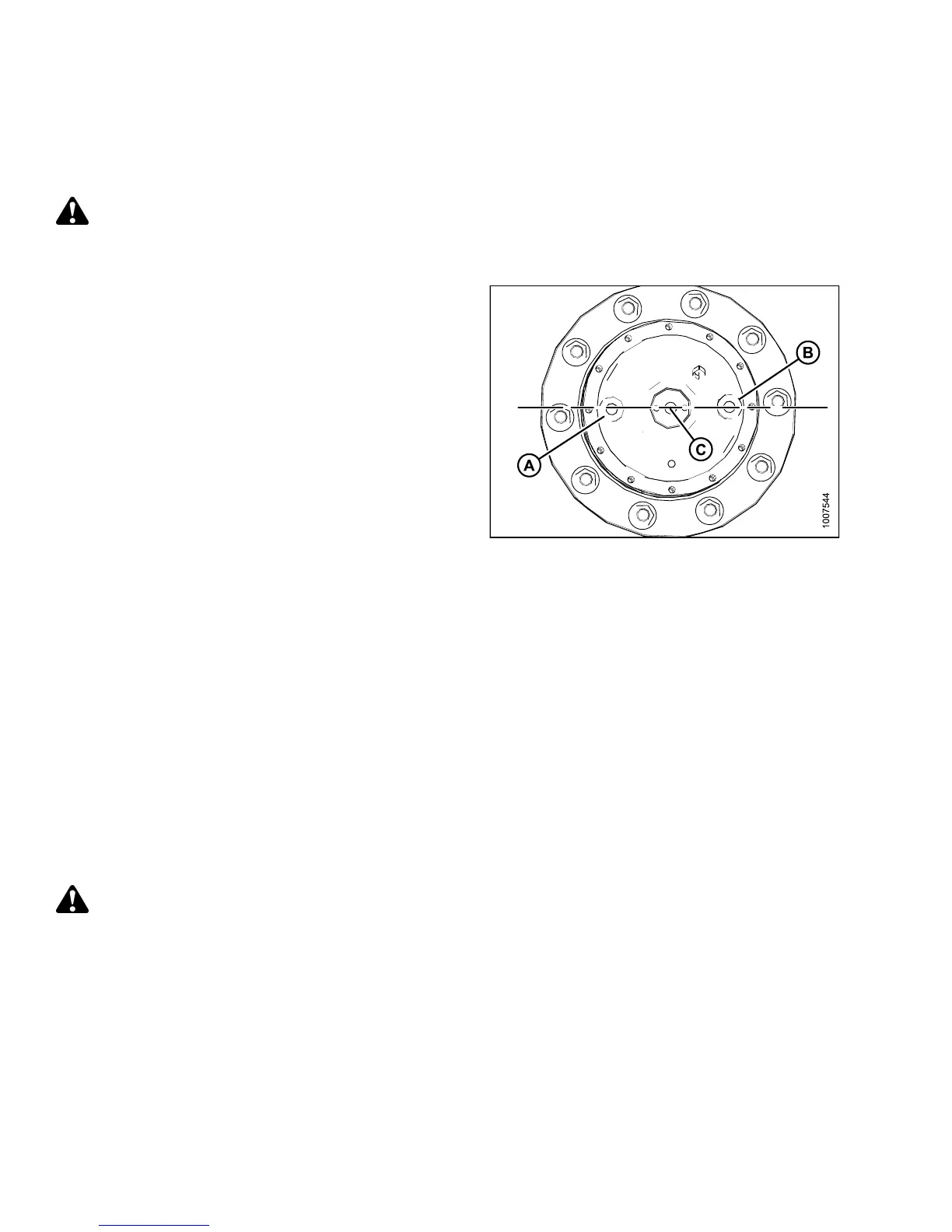

1. Rotate the wheel drive so plugs (A) and (B) are

horizontal (C).

2. Stop windrower and remove key from ignition.

3. Remove the two plugs (A) and (B). The oil should be

visible through the hole, or slightly running out.

4. If lubricant needs to be added, remove the second

plug (B), and add lubricant until lubricant runs out at

(A). Refer to 8.2.3 Lubricants, Fluids, and System

Capacities, page 466.

NOTE:

PRIOR TO F IRST C HAN GE : use SAE 85W140,

API Service, Class GL-5, Extreme Pressure Gear

Lubricant.

NOTE:

AFTER FIRST CHANGE: use SAE 75W90, API

Service, Class GL-5, Fully Synthetic Transm issio n

Lubricant (SAE J2360 preferred).

5. Reinstall and tighten plugs (A) and (B).

Figure 5.203: Wheel Drive Assembly

6. Start up and operate the windrower for a few minutes,

then stop and check the oil level. Refer to Checking

Wheel Drive Lubricant Level, page 413. If n ecessary,

add m ore oil.

Changing Wheel Drive Lubricant

The wheel drive lubricant should be changed after the first 50 hours and then in accordance with the maintenance

schedule. Change the lubricant when it is warm.

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove

the key from the ignition before leaving the operator’s seat for any reason.

147649

4

14

Revision A

Loading...

Loading...