MAINTENANCE AND S ERVICING

Check tire pressure every year. Caster tire pressure should be 10 psi (69 kPa).

To maintain pressure, visually check daily that tires have not lost pressure, and adjust pressure as needed.

Under-inflation of tires can cause sidewall cracks.

NOTE:

If caster wheels shimmy, a possible cause is ov er-inflation.

Table 5.5 Cas

ter Tire Options

Formed Caster Forked Caster

7.5–16SL Single Rib, 10-16 Front Steer Tire

16.5L–16.1 Rib Implement Flotation, 10–16

Front Steer Tire

10 psi (69 kPa) 10 psi (69 kPa)

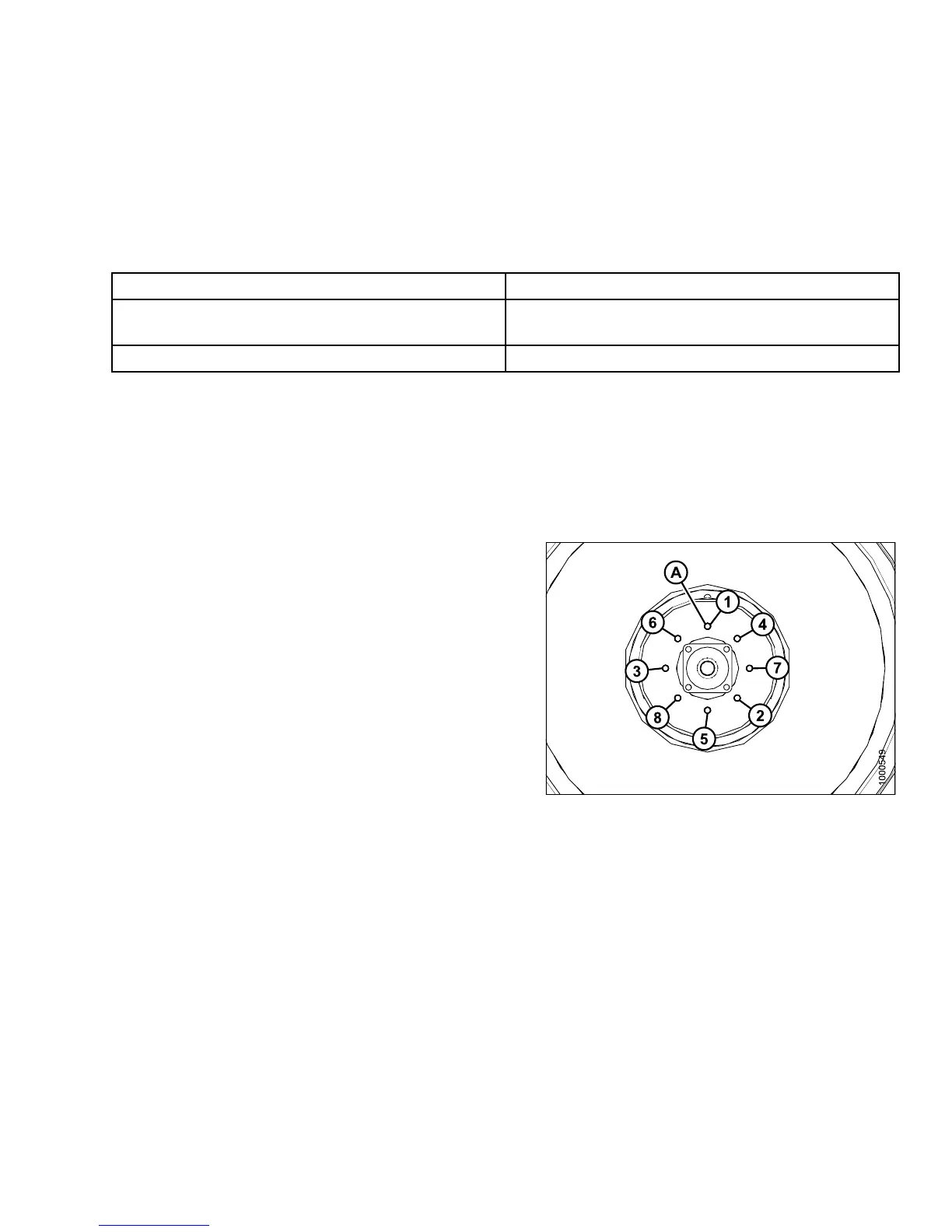

Tightenin

g Caster Wheel Nuts

At first use or when a wheel is removed, check wheel nut/bolt torque every 15 minutes on the road or 1 hour in the

fielduntilthespecified torque is maintain ed.

Once specified torque is maintained, check wheel nut/bolt torque after 10 and 50 hours (field or road operation) and

then every 200 hour intervals thereafter.

To tigh ten the caster wheel nuts on eit her forked or formed

caster wheels , follow these s teps:

1. Position wheel assembly on hub and install wheel

bolts (A).

2. Tighten wheel nuts (A) to 120 ft·lbf ( 163 N·m) using

the tightening sequence s uitable for the type of caster

wheel shown at right. Repeat the tightening sequence

three times.

Figure 5 .213: Forked Caster Wheel

Tightening Sequence

147649 419 Revision A

Loading...

Loading...