April 2017

8-37

Xerox® VersaLink® B7025/B7030/B7035 Multifunction Printer

Product Technical Overview

Launch Issue

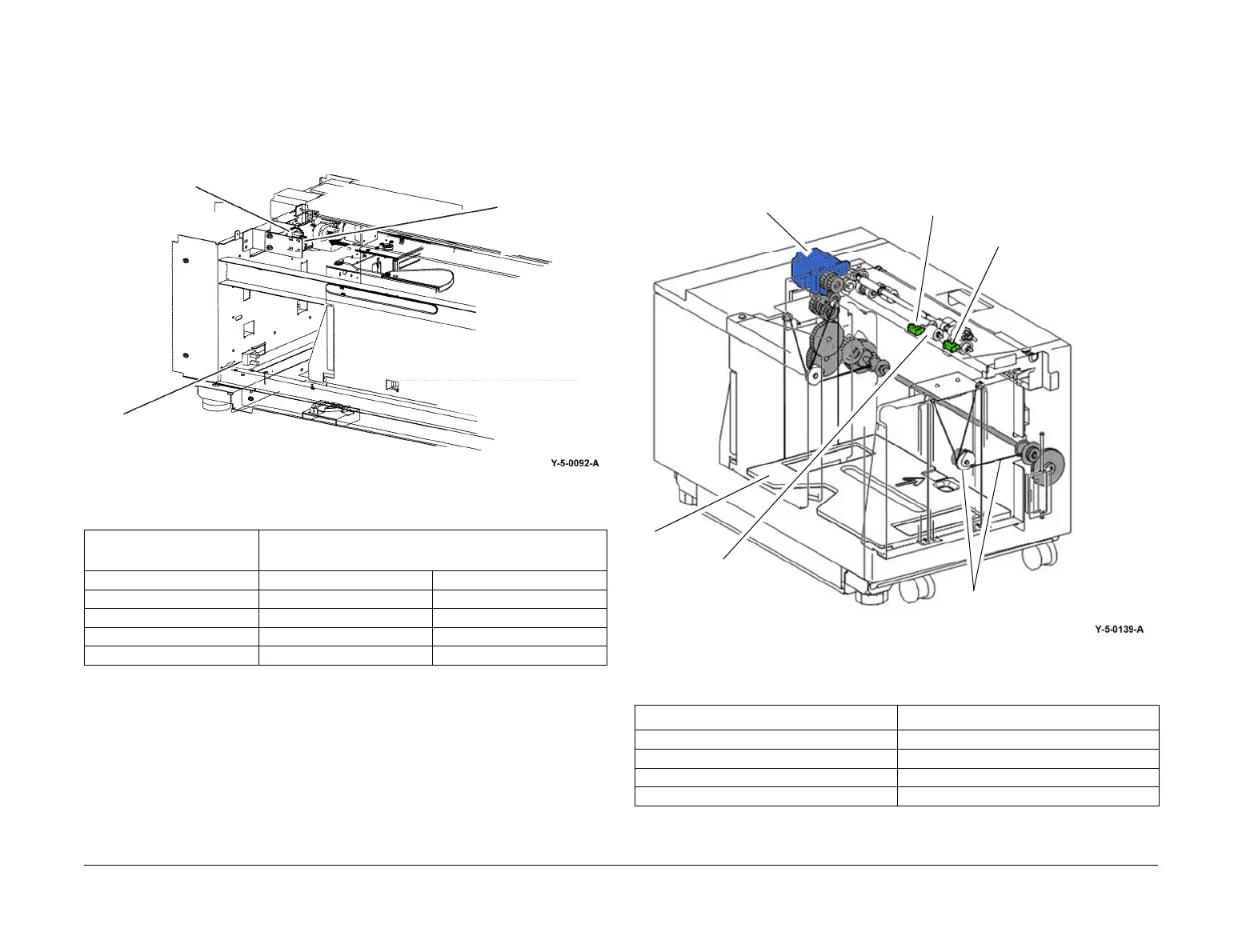

High Capacity Feeder: Loading and Size Sensing

When the HCF tray is pulled out to load paper, the lift gear is separated from the drive gear and

the tray is free to fall to the bottom position. A torque limiter on the lift shaft slows the fall of the

paper tray to prevent damage to feeder components.

Size sensing is determined by the HCF size sensor (A) and the HCF size sensor (B). The

paper tray guides actuate the size sensors, Figure 21 and Table 1.

Figure 21 HCF tray in and paper size sensors

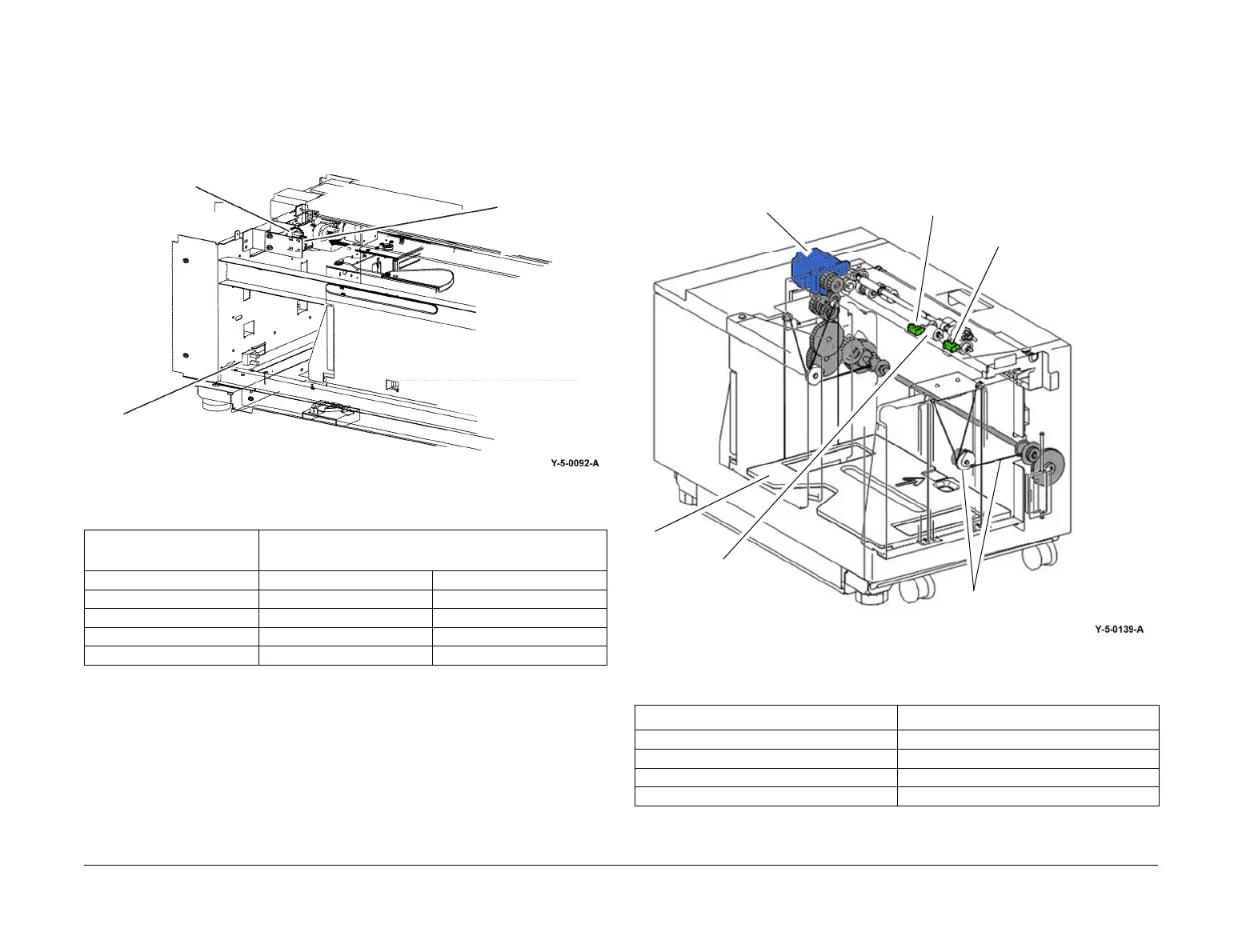

High Capacity Feeder: Tray Lift Operation

When the HCF tray is pushed in and actuates the HCF tray in sensor, Figure 21, the following

sequence of events occurs, refer to Figure 22:

1. The nudger roll is lowered.

2. The HCF feed/lift motor switches on and rotates CCW to lift the tray through a pulley and

cable arrangement.

3. Lift continues until the paper stack reaches and lifts the nudger roll, deactuating the HCF

level sensor.

4. The HCF feed/lift motor switches off.

High Capacity Feeder: Remaining Paper Calculation

The control logic calculates the amount of paper that remains in the HCF tray by the time it

takes for the paper stack to deactuate the HCF level sensor, Figure 22. The value is then dis

-

played on the UI for operator information. Refer to Table 2 for the time/quantity relationship.

If the HCF is empty, the HCF no paper sensor will actuate, and a Tray Empty message will dis-

play, Figure 22.

Figure 22 HCF level sensor

Table 1 Paper size by sensor state

Paper Size

Tray Paper Size Sensor

Sensor B Sensor A

B5 LEF or 7.25x10.5 inch LEF OFF OFF

8.5x11 inch LEF OFF ON

A4 LEF ON OFF

Long A4 (Irregular Settings) OFF OFF

HCF size senso

A, (letter)

HCF size sensor

B, (A4)

HCF tray in sensor

Table 2 Time/quantity relationship

Paper Remaining Lift Time (msec)

25% 8798-11526

50% 6068-8797

75% 3338-6067

FULL 0-3337

HCF level sensor

HCF no paper sensor

Nudger roll

HCF feed/lift motor

Tray

Pulley and cable

Loading...

Loading...