3

© 2011 - 2015 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO5540C/6540C/6550C/5560C/6560C/6570C

OUTLINE OF THE MACHINE

3 - 43

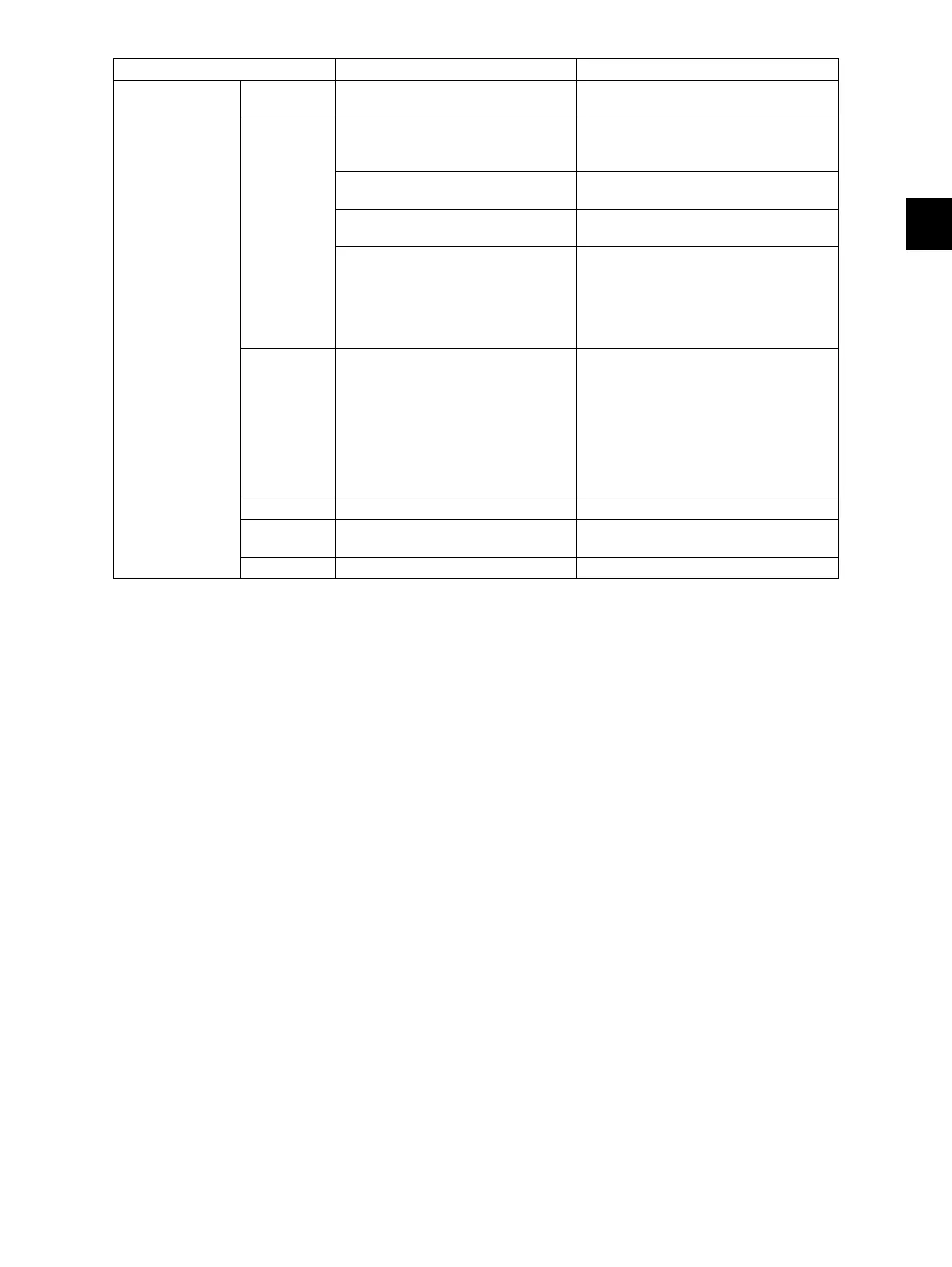

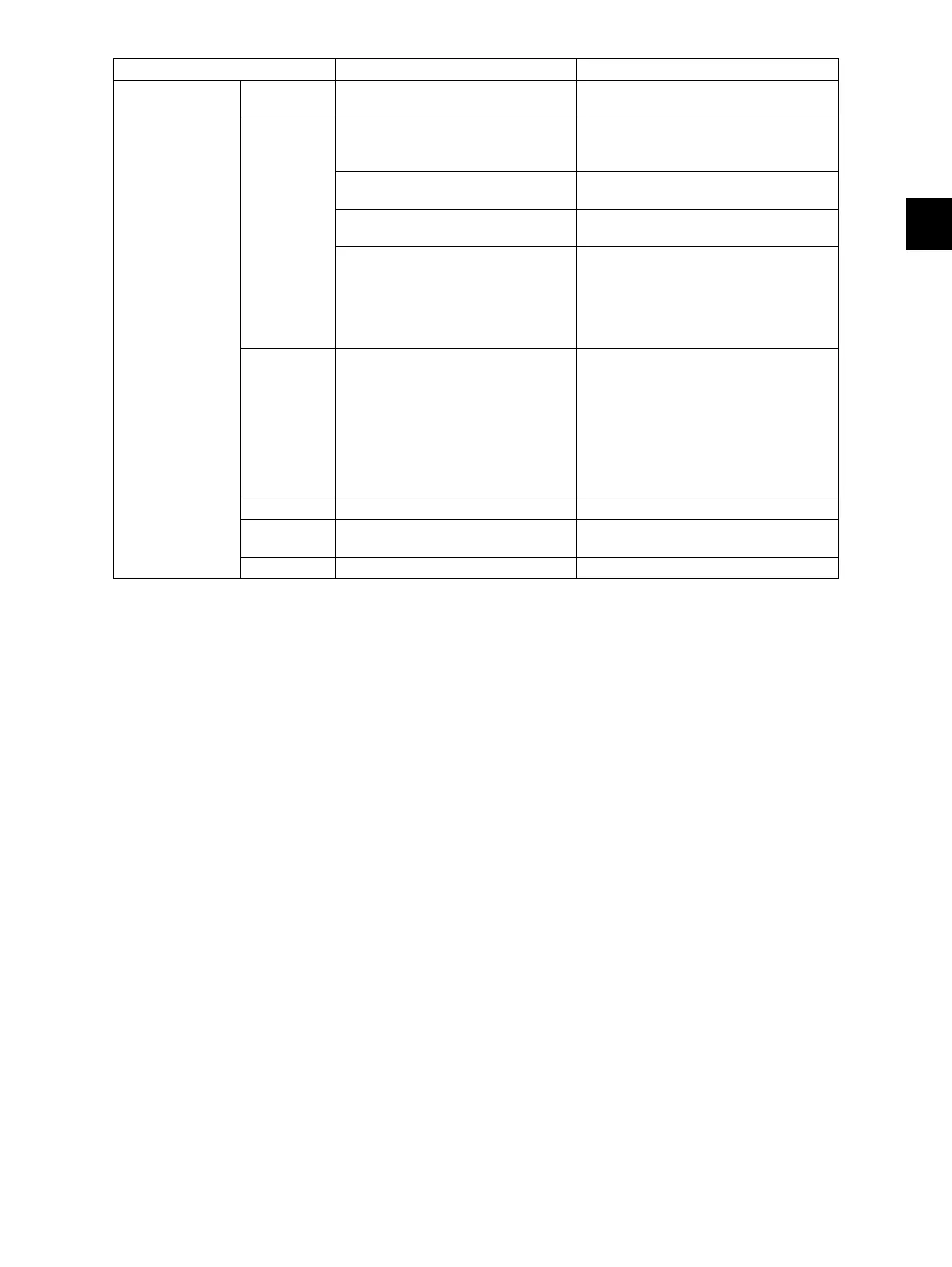

11.Fusing Method External heating STF fusing system External IH heating fusing and heat

pipe roller soaking systems

Fuser roller

side

Satellite roller:

Aluminum roller (ø17)

Heat pipe roller:

Roller in which a heat pipe is

embedded (ø17.4)

Fuser roller:

Sponge roller (ø48.5)

Fuser belt:

PFA tube belt (ø60)

IH coil: 2 coils

• 200 to 1240W (for MJC/

MJD)

• 200 to 1100W (for NAC/

NAD, ASU, ASD, ARD,

AUC/AUD, CND)

IH coil: 1 coil

• 200 to 1240W (for MJC/MJD)

• 200 to 1100W (for NAC/NAD,

ASU, ASD, ARD, AUC/AUD,

CND)

Pressure

roller side

Pressure roller:

Silicon rubber roller,

(Surface-PFA tube)(ø50)

Heater lamp:

• 300 W x 2 (for NAC/NAD)

• 300 W x 2 + 800 W x 1 (for

MJC/MJD)

• 300 W x 2 (for ASU, ASD,

ARD, AUC/AUD, CND)

Cleaning None

Heater

temperature

ON/OFF control and power control

by thermopile/thermistor

Heater IH coil + Heater lamp

Process e-STUDIO5520C/6520C/6530C e-STUDIO5540C/6540C/6550C

Loading...

Loading...