e-STUDIO5540C/6540C/6550C/5560C/6560C/6570C © 2011 - 2015 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

3 - 42

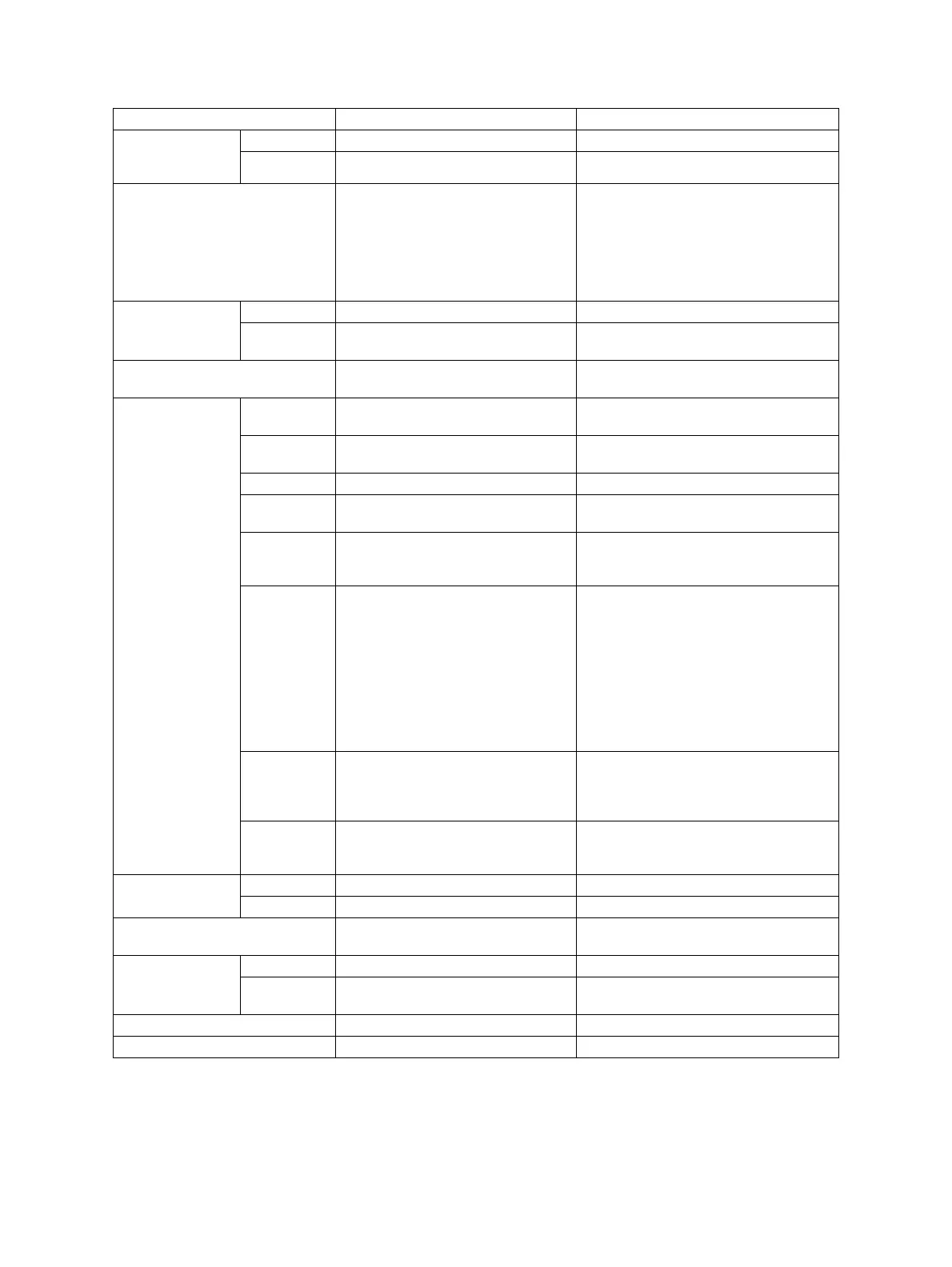

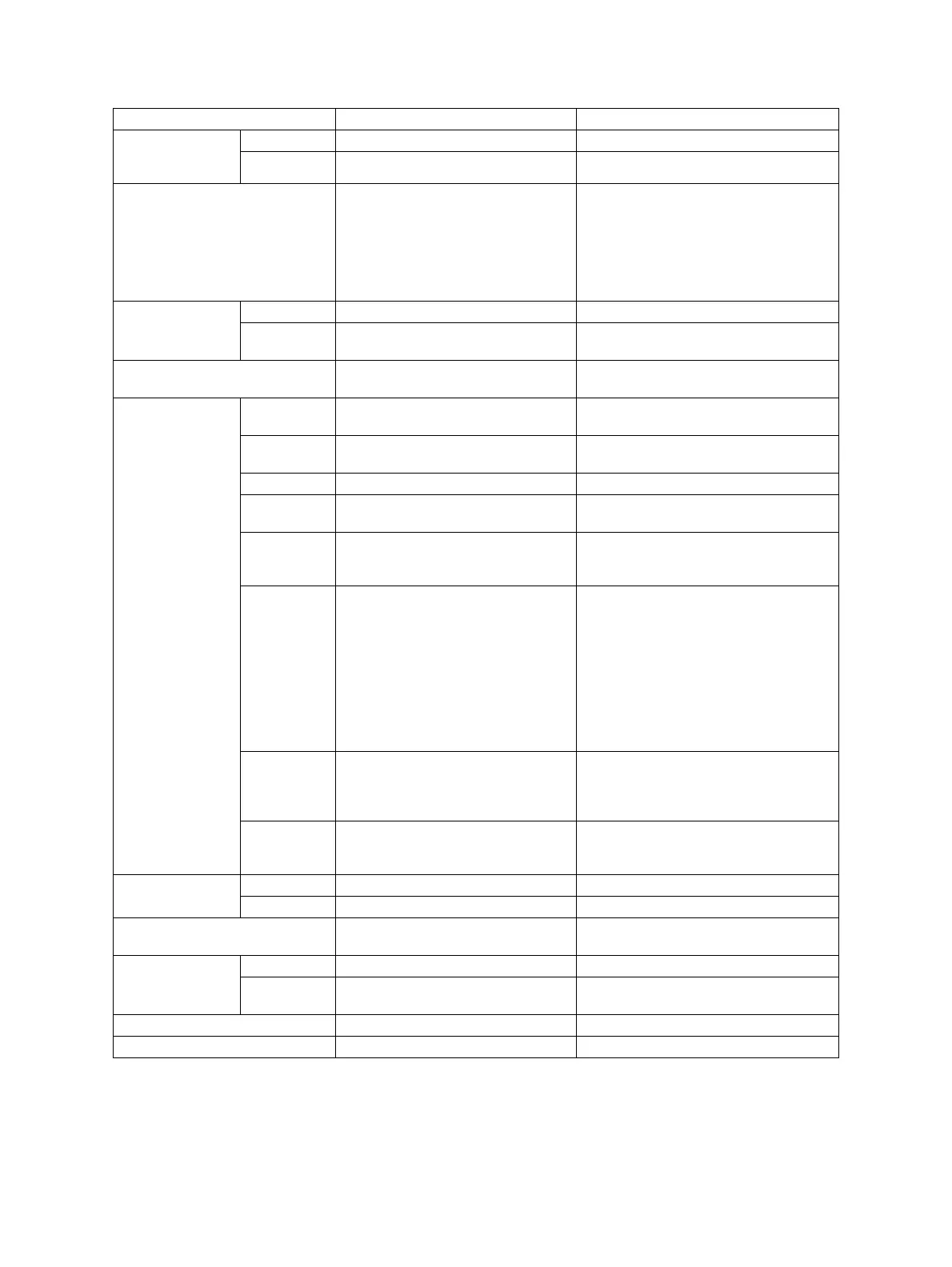

3.5 Comparison with e-STUDIO5520C/6520C/6530C

Process e-STUDIO5520C/6520C/6530C e-STUDIO5540C/6540C/6550C

1.

Photoconductive

drum

Drum OD-FC55 (OPC drum)

Sensitivity Highly sensitized drum (ø60)

2. Charging Scorotron type

-250 to -1200 V (grid voltage)

(adjusting by image quality

control)

(feedback control with the surface

potential sensor)

(Feedback control with the surface

potential sensor only for K station in e-

STUDIO6550C)

3. Data writing Light source Semiconductor laser

Light

amount

3.25 nJ/mm

2

4. Image control Image quality control by detecting

toner adhesion amount

5. Development Magnetic

roller

One magnetic roller

Auto-toner

detection

Magnetic bridge-circuit method

Toner supply Toner cartridge replacing method

Toner-empty

detection

Density detection method

Cartridge-

empty

detection

Sub-hopper toner remaining

amount detection method

Toner NAC/NAD T-FC55-K, T-FC55-Y

T-FC55-M, T-FC55-C

MJC/MJD T-FC55-EK, T-FC55-EY

T-FC55-EM, T-FC55-EC

CND T-FC55-CK, T-FC55-CY

T-FC55-CM, T-FC55-CC

Others T-FC55-DK, T-FC55-DY

T-FC55-DM, T-FC55-DC

(K: Black, Y: Yellow, M: Magenta, C:

Cyan)

NAC/NAD T-FC65-K, T-FC65-Y

T-FC65-M, T-FC65-C

MJC/MJD T-FC65-EK, T-FC65-EY

T-FC65-EM, T-FC65-EC

CND T-FC65-CK, T-FC65-CY

T-FC65-CM, T-FC65-CC

Others T-FC65-DK, T-FC65-DY

T-FC65-DM, T-FC65-DC

(K: Black, Y: Yellow, M: Magenta, C:

Cyan)

Developer

material

D-FC55-K (black)

D-FC55-Y (yellow)

D-FC55-M (magenta)

D-FC55-C (cyan)

Developer

bias

DC -100 to -900V (adjusting by

image quality control)

AC 1000 V / 8 to 13kHz

6. Transfer 1st transfer Transfer belt method

2nd transfer: Transfer roller method

7. Separation Self-separation by transfer belt and

2nd transfer roller

8.

Photoconductive

drum cleaning

Method Blade cleaning

Recovered

toner

Non-reusable

9. Transfer belt cleaning Blade cleaning

10.Discharge LED array (red)

Loading...

Loading...