2-12 Phaser 6300/6350 Color Laser Printer Service Manual

2. Light Density Adjustment

At the execution of Automatic Density Control, the Light Density Adjustment is

made just before the toner patches for toner density control are generated.

Light is emitted from the LED using the current Light Density Setting, to check if the

output value of the CTD (ADC) Sensor is within the specified range. If the output

value is low, light density is increased. If the output value is high, light density is

decreased.

If the output value is less than the first lower limit, a warning message indicates the

sensor is dirty. If the output value is less than the second lower limit, a Fatal Error

signals that the sensor is faulty and the printer stops printing.

Color Registration Control

The printer uses a quad system where drums and developers are used exclusively for

each of the four colors (yellow, magenta, cyan, and black). Images are formed on the

drums, in the respective colors, and then layered to form one image. To avoid a

positional shift between the different color images, the color registration control

calculates how much the registration has shifted by comparing each of the other color

patches in the registration string to the black bar that precedes it. Shift is corrected by

adjusting the laser write timing to compensate.

Color registration control is made depending on the internal temperature and print

count at the execution of process control.

This control is outlined below:

1. With no toner on the Transfer Roller, the output value of the CTD (ADC) Sensor

is measured to determine the reference value.

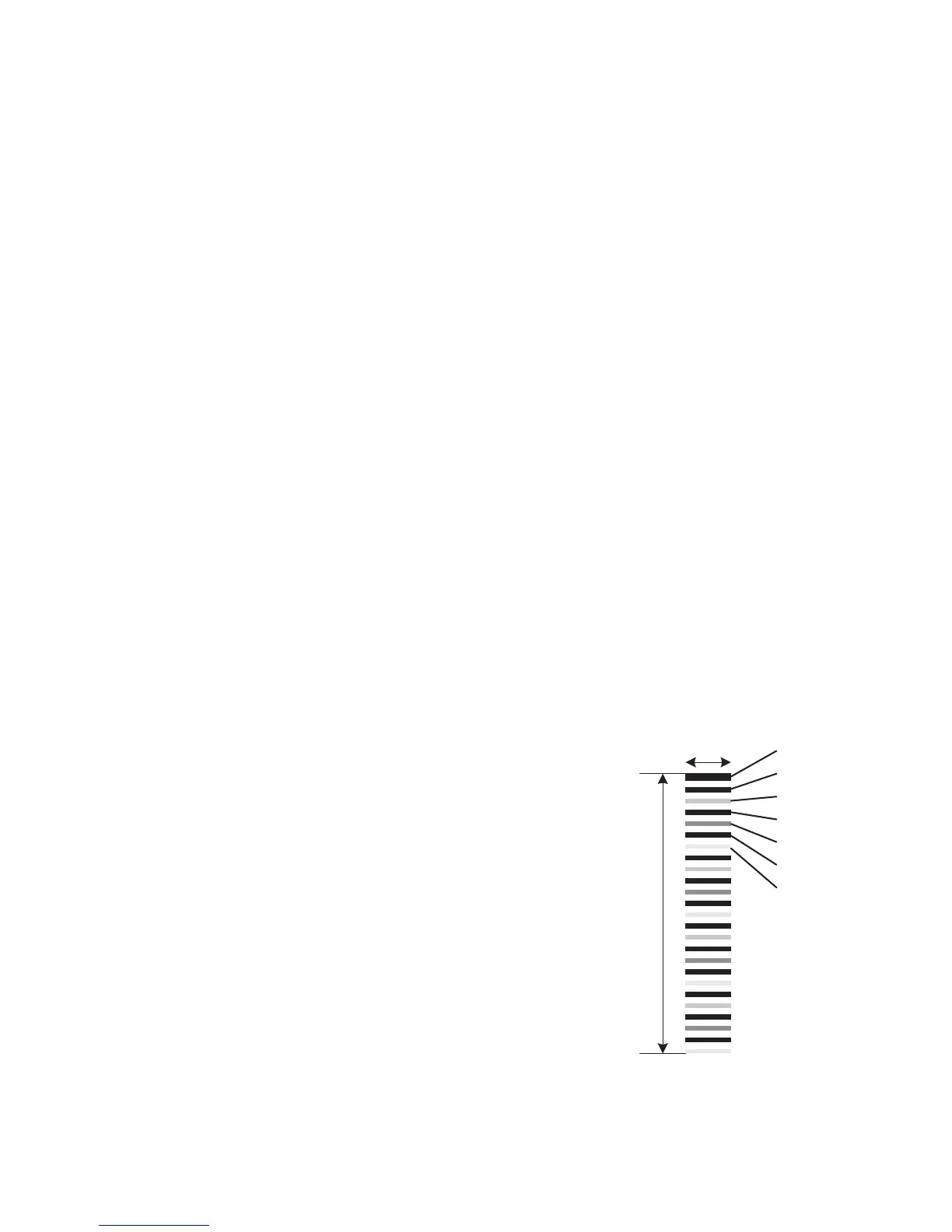

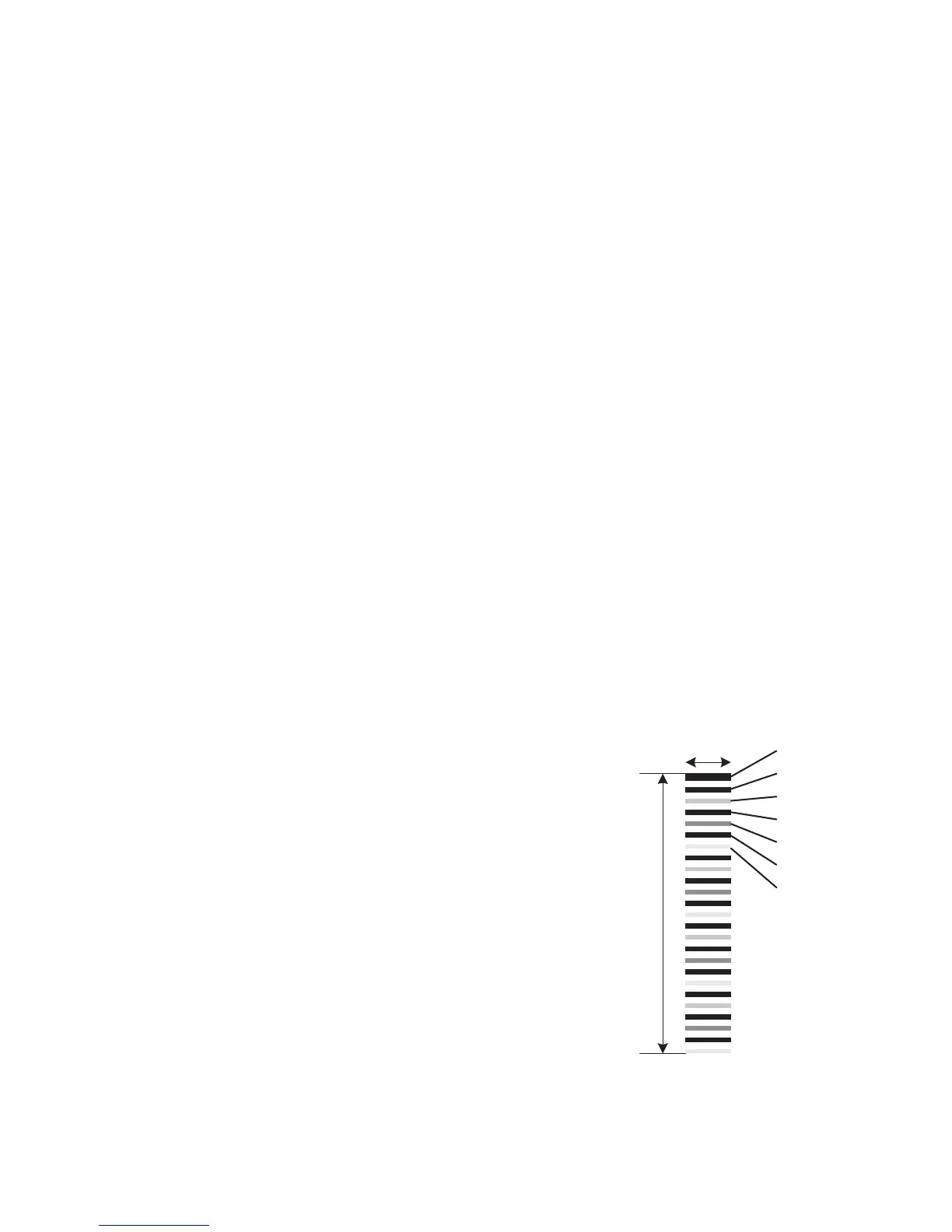

2. Patches for color registration control are

generated on the Transfer Roller. These

patches are composed of 10 mm lines of

each toner color in the following order: K,

C, K, M, K. The string of patches is led by a

black trigger patch that is larger than the

registration patches.

3. The density of patches generated is

measured by the CTD (ADC) Sensor.

4. The amount of registration shift is

calculated from the reference value

determined in Step 1 and the patch density

measured in Step 3.

5. The laser write timing is changed to

compensate for any registration shift.

10 mm

About One Turn

Of Transfer Roller

s6300-068

K

K

C

K

M

K

Y

Loading...

Loading...