Theory of Operation 2-9

Process Control

For stable printing, the parameters related to forming both the electrostatic and toner

image are continuously monitored and adjusted by the printer. Parameter correction

and control over the entire printing process is called “process control”. There are two

main areas of control:

■ Bias Control

■ Toner Density Control

To supplement these two controls, the following are provided:

■ High-Area Coverage Mode Control

■ Admix Mode Control

■ Toner Density Control (CTD) Sensor (ADC - Automatic Density Control) LED

light density setting.

Bias Control

To attain stable image density, toner density is monitored for each color and the drum

charging voltage and biasing DC voltages are adjusted accordingly.

The bias control adjustment is made immediately before the start of printing, if any of

the following conditions is satisfied:

■ First print produced after the power on.

■ Cumulative print count exceeds 16 since power on.

■ A cleaning cycle is executed during continuous printing.

Bias control operates as follows:

1. The Temperature/Humidity Sensor provides input to establish target values of the

drum charging voltage and biasing DC voltage.

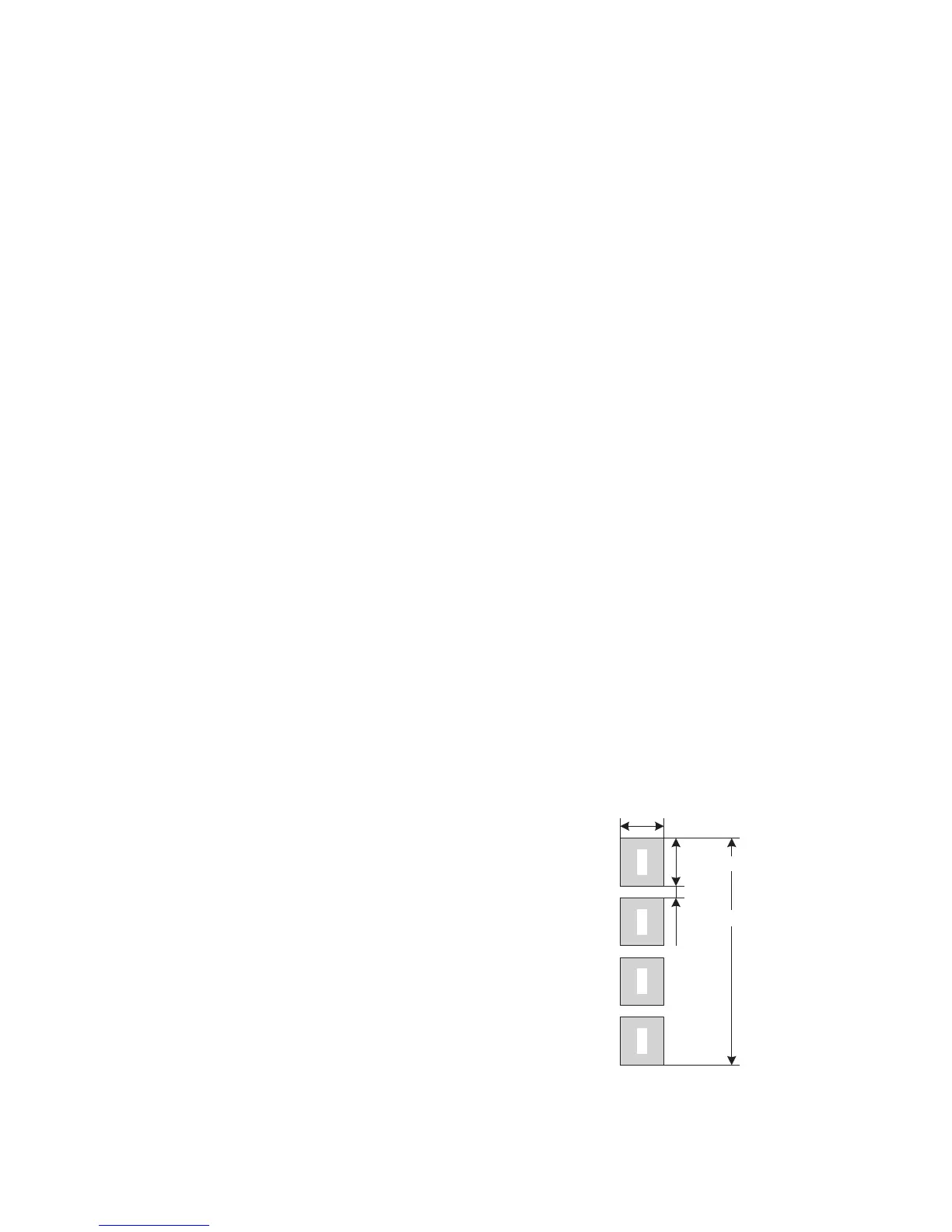

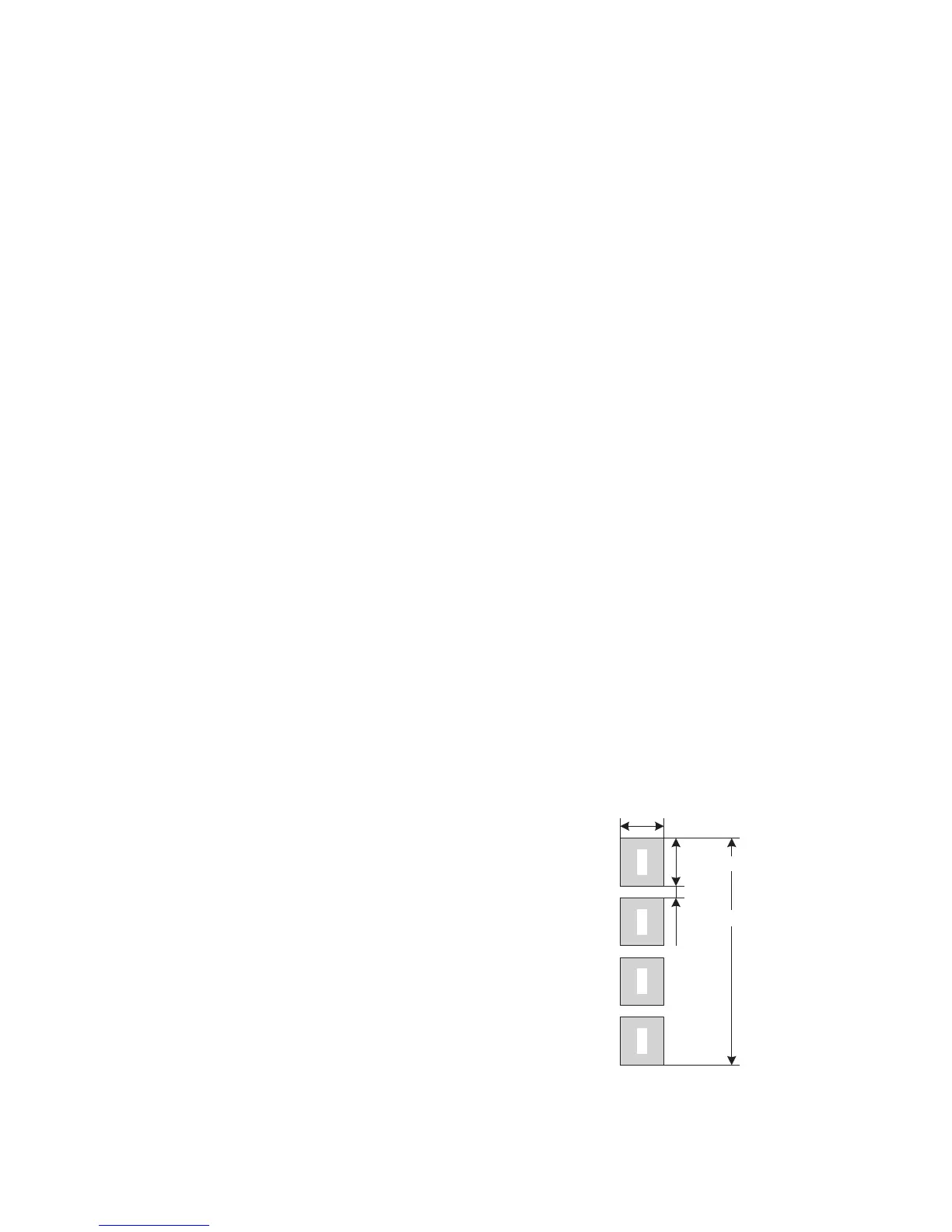

2. Bias control test patches (see the adjacent figure

for patch configuration) of each of the four toner

colors (yellow, magenta, cyan, and black) are

generated and transferred to the Transfer Roller.

3. The CTD (ADC) Sensor compares an area on the

Transfer Roller where no toner is present with the

test patches to determine toner density for each of

the four colors.

4. The density measured in Step 3 is compared with

the target value set in Step 1 and the resulting

difference is used to adjust the drum charging

voltage and the biasing DC voltage for each toner

color.

Y

M

C

K

About 11 mm

About 57 mm

s6300-066

About 12 mm

About 3 mm

Loading...

Loading...