Model 6 Motor Control Centers 80459-641-01E

Section 6—Maintaining the MCC 10/2012

© 1999–2012 Schneider Electric All Rights Reserved62

ENGLISH

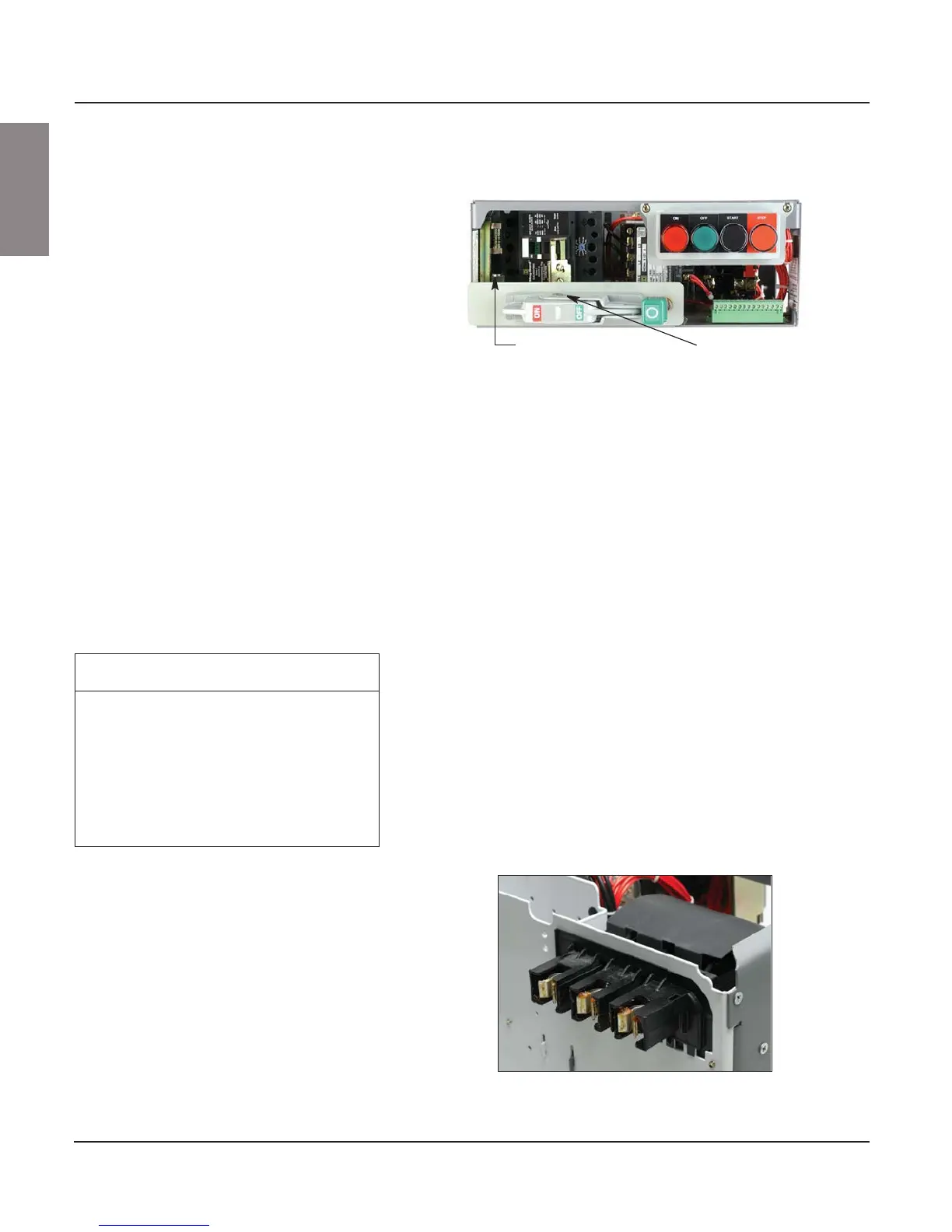

8. Grasp the operator handle flange and press down on the structure

interlock release (see Figure 87).

9. Firmly pull the unit forward to disengage the power stabs from the

vertical bus. The unit should now slide freely from the MCC structure.

10. The operator mechanism-to-structure interlock prevents the control unit

from being inserted or withdrawn with the handle in the ON position.

11. If the withdrawn unit is left in the structure, use appropriate lock-out/tag-

out procedures to avoid re-loading by non-authorized personnel.

12. Remove the control unit from the structure and place it on a flat surface

for servicing.

NOTE: Partial disassembly of the unit may be necessary to gain access

to various electrical connections for servicing.

Tests and Maintenance Performed

with the Control Unit Removed

Once the control unit is removed, perform the following tests and

maintenance:

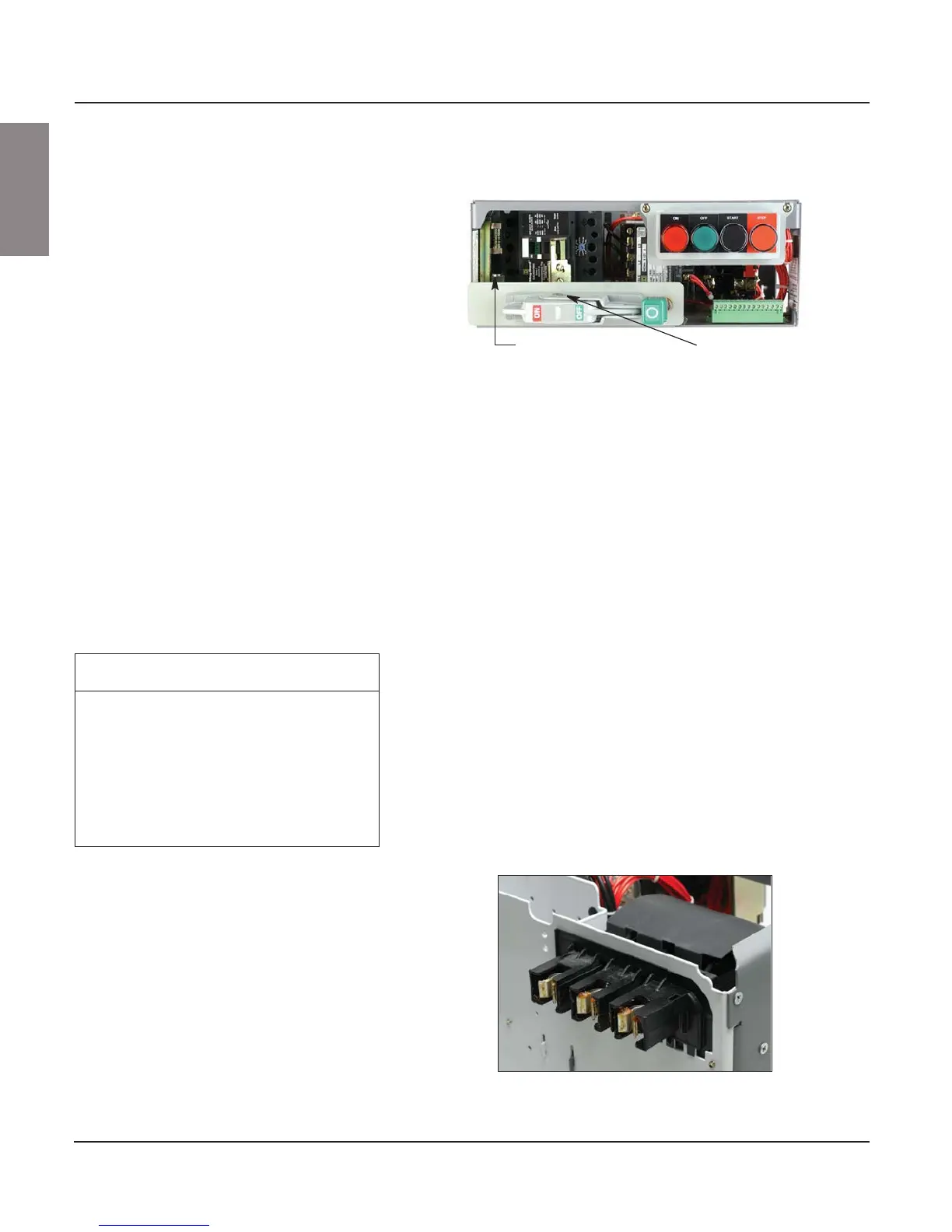

Stab Assemblies—Inspect the stab assemblies (see Figure 88) for signs of

arcing or overheating. Replace the disconnect assembly (FA/KA type

circuit breakers) or the jaw connector assembly (H- or J-frame circuit

breakers) immediately if overheating has occurred. For replacement

disconnect assemblies, see “Section 13—Circuit Breaker and Fusible

Switch Replacement” beginning on page 111.

NOTE: If the stab assembly is badly pitted, the vertical bus may also need

to be replaced.

Figure 87: Operator Handle and Interlock Release

Operator handle flang

Structure interlock release

NOTIC

HAZARD OF EQUIPMENT DAMAGE

Do not remove the protective lubricant from the

stabs. If additional lubricant is required, order

Schneider Electric electrical joint compound

#PJC-7201.

Failure to follow this instruction can result

in equipment damage.

Figure 88: Stab Assembly

Loading...

Loading...