80459-641-01E Model 6 Motor Control Centers

10/2012 Section 4—Installing the MCC

© 1999–2012 Schneider Electric All Rights Reserved

51

ENGLISH

Cable Connection Torque Values The following tables provide main disconnect and branch feeder torque

values, which apply to both aluminum and copper conductors.

Component Instructional

Information

Component manuals for devices such as adjustable frequency drive

controllers, solid state reduced voltage starters, and programmable logic

controllers are included with the MCC instruction information packet.

Thermal overload selection data is listed on the inside of the vertical wire

trough door of each section. This information is also listed in this bulletin;

see “Thermal Overload Unit Selection” beginning on page 105. Select

proper thermal overloads from the applicable starter size tables.

Figure 66: Main Lug Compartment Torque

Connection

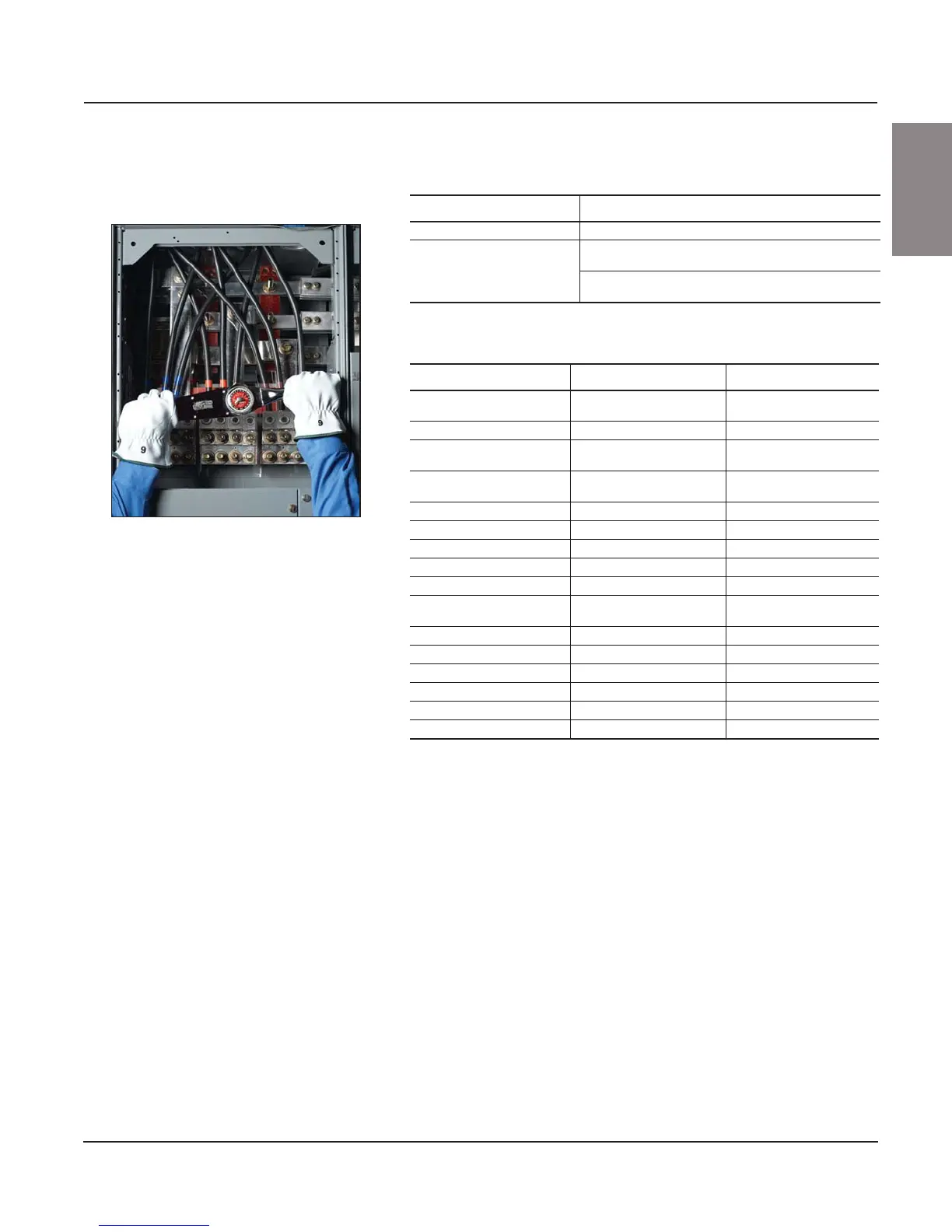

Table 4: Connection Torque Values for Main Lug Compartments

1

1

See Figure 66.

Socket Size Across Flat Torque

3/8 in. 375 lb-in (42.4 N•m)

1/2 in.

500 lb-in (55.6 N•m)

for 800–1200 A, bottom main lug compartments

600 lb-in (67.8 N•m)

for all others

Table 5: Connection Torque Values for Main and Branch Feeders

Frame Size Ampere Rating Torque

H

15–30 A

35–150 A

50 lb-in (5.6 N•m)

120 lb-in (13.6 N•m)

J 150–250 A 225 lb-in (25.4 N•m)

FA

15–30 A

35–100 A

35 lb-in (3.9 N•m)

80 lb-in (9.0 N•m)

FC

20–30 A

40–100 A

35 lb-in (4.0 N•m)

65 lb-in (7.3 N•m)

KA 70–250 A 250 lb-in (28.2 N•m)

KC 110–250 A 250 lb-in (28.2 N•m)

LA/LH 125–400 A 200 lb-in (22.6 N•m)

LC/LI/LE/LX/LXI 300–600 A 300 lb-in (33.9 N•m)

LG/LH/LL/LR 300–600 A 442 lb-in (50 N•m)

MA/MH/ME/MX

200–400 A

450–1000 A

300 lb-in (33.9 N•m)

300 lb-in (33.9 N•m)

NT 400–1200 A 600 lb-in (67.8 N•m)

NW (top entry) 400–2500 A 600 lb-in (67.8 N•m)

PA/PH/PE/PX 800–2000 A 600 lb-in (67.8 N•m)

MJ/MG 300–800 A 450 lb-in (50.8 N•m)

PJ/PK/PG/PL 250–1200 A 450 lb-in (50.8 N•m)

RJ/RK/RG/RL 600–2500 A 500 lb-in (56.5 N•m)

Loading...

Loading...