80459-641-01E Model 6 Motor Control Centers

10/2012 Section 7—Motor Logic™ Solid-State Overload Relay (SSOLR)

© 1999–2012 Schneider Electric All Rights Reserved

71

ENGLISH

Box lugs (on interposing power terminal blocks supplied with selected units)

are suitable for wire sizes #14–8 AWG, solid or stranded. Terminal

instruction labels are located adjacent to the terminal block. Table 8 provides

additional termination data.

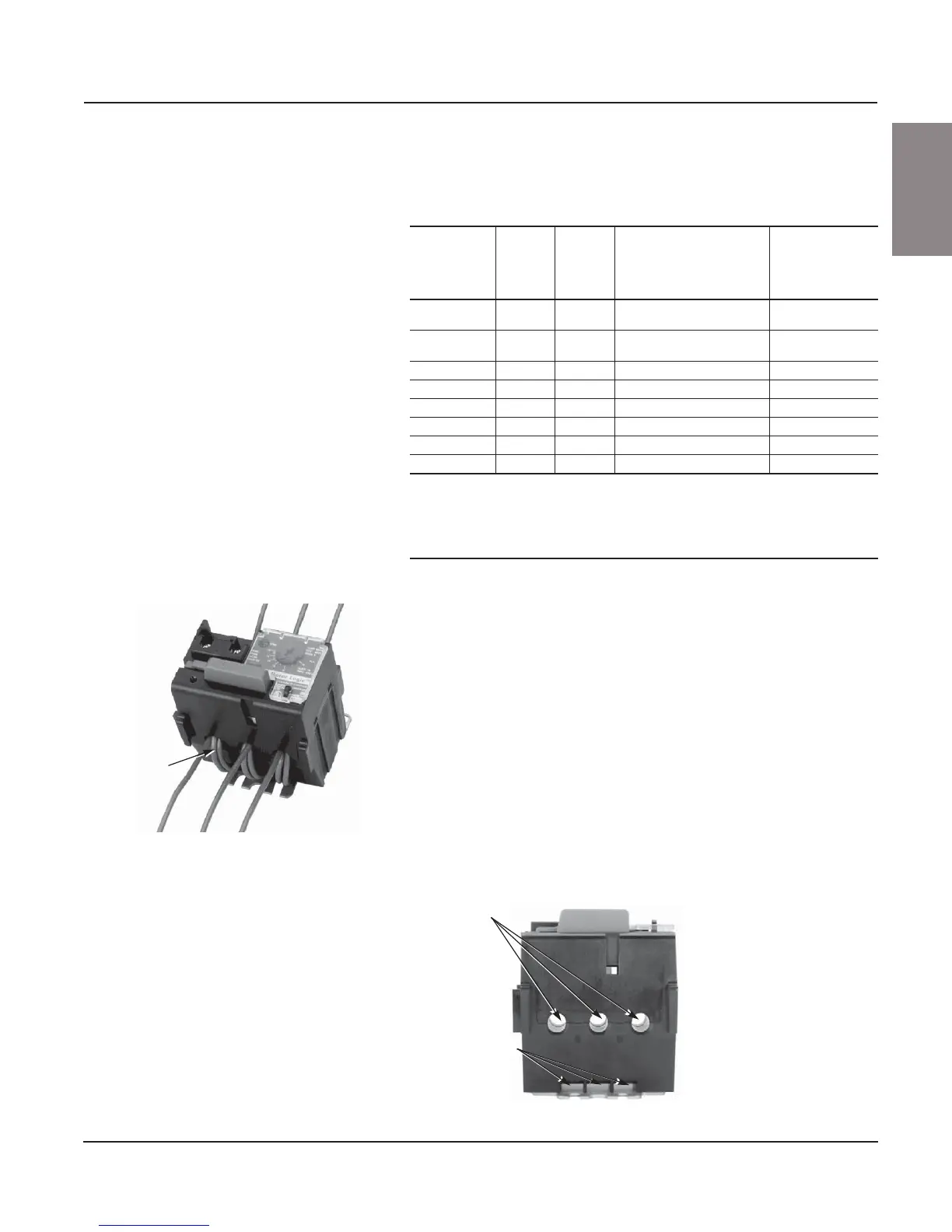

Size 00B, 00C, 0, and 1 relays have conductor (CT) windows through which

the motor leads must pass before being connected to the load terminals on

the contactor (T1, T2, and T3). By allowing multiple passes (turns) of the

load leads through these CT windows, overload protection can be provided

for motors with a full-load current lower than the specified operating range.

Two passes of the load leads through each window effectively increase (by

a multiple of two) the current that the overload relay senses. Three passes

effectively increase the current by a multiple of three. All three conductor

windows must have the same number of passes, looped in the same

direction, for the overload relay to operate properly (see Figure 101).

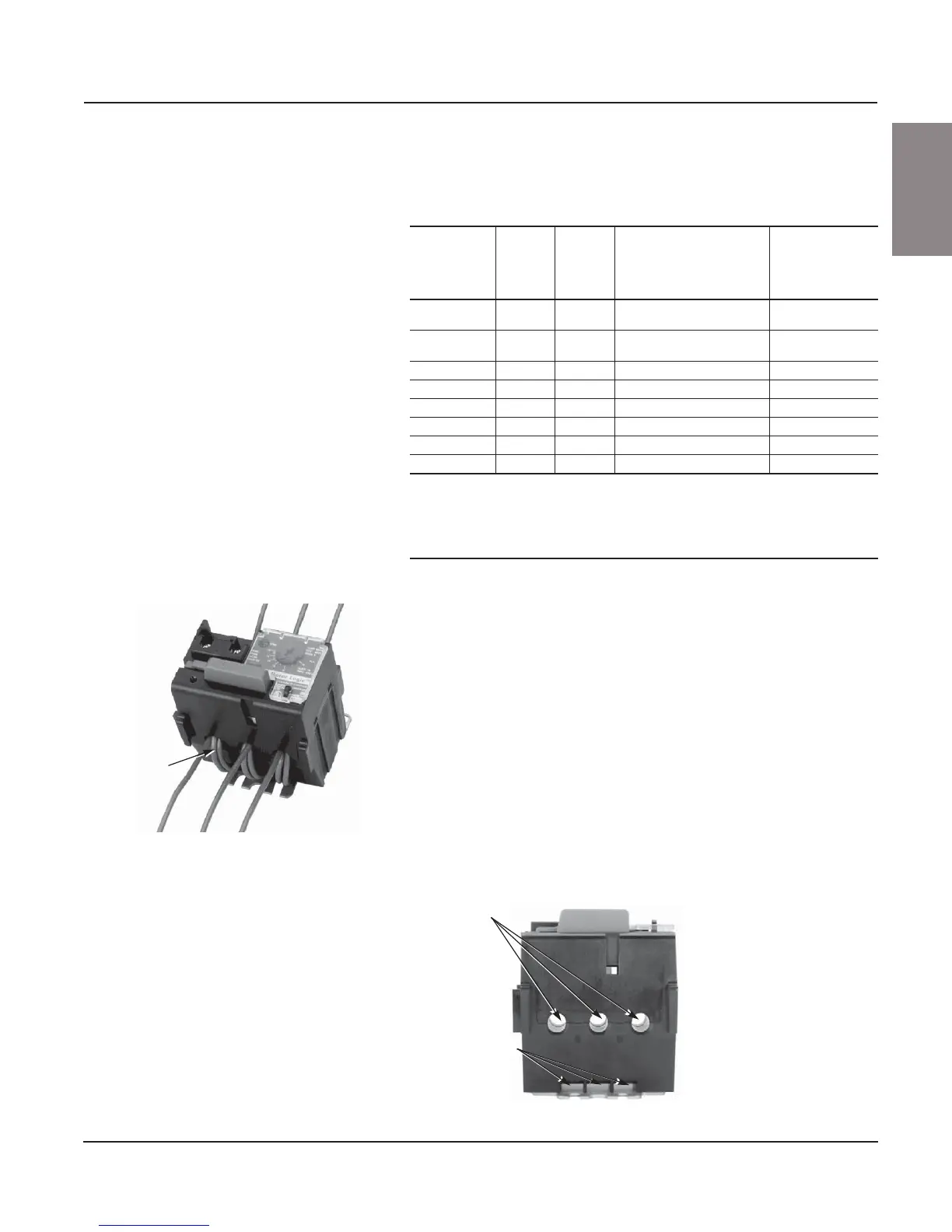

Passes should begin from the load side of the overload through the CT window

and return via the windows provided between the baseplate and overload (see

Figure 102). The final pass terminates on the load side of the contactor.

MCC units requiring multiple passes are factory supplied prelooped with

#14 AWG wire and interposing terminal blocks. Refer to “Motor Logic

Retrofit Applications” on page 70 for information concerning retrofit.

Table 8: Lug Types and Wire Sizes

Class 9065

Motor Logic

Overload

Relay Size➀

Rating

Lug

Type

Wire Size➁ Torque Values➃

00B 1.5–4.5 A

Pressure

Wire➂

14–8 AWG (2.5–6 mm

2

) 25 lb-in (2.8 N•m)

00C 3–9 A

Pressure

Wire➂

14–8 AWG (2.5–6 mm

2

) 25 lb-in (2.8 N•m)

0 6–18 A Box Lug 14–4 AWG (2.5–16 mm

2

) 50 lb-in (5.6 N•m)

1 9–27 A Box Lug 14–4 AWG (2.5–16 mm

2

) 50 lb-in (5.6 N•m)

3 30–90 A Box Lug 14–1/0 AWG (2.5–50 mm

2

) 100 lb-in (11.3 N•m)

4 45–135 A Box Lug 8–250 MCM (6–120 mm

2

) 200 lb-in (22.6 N•m)

5 90–270 A Box Lug 250–500 MCM (120–240 mm

2

) 250 lb-in (28.2 N•m)

6 180–540 A Clamp Lug 250–500 MCM (120–240 mm

2

) 375 lb-in (42.4 N•m)

➀ Refer to the overload relay label next to the adjustment dial.

➁ Solid or stranded copper wire, 140 or 167 °F (60 or 75 °C), except 45 to 135 A overload

relay, which is 67 °F (75 °C) wire only.

➂ Box lug kit may be supplied, suitable for 14 to 4 AWG wire, 50 lb-in (5.6 N•m) tightening torque.

➃ Does not apply to Compac 6 units.

Figure 101: Looping Passes

3 passes shown

(load side)

Figure 102: Motor Logic Overload (Bottom View)

CT windows

Return windows

(multiple passes)

Loading...

Loading...