Model 6 Motor Control Centers 80459-641-01E

Section 7—Motor Logic™ Solid-State Overload Relay (SSOLR) 10/2012

© 1999–2012 Schneider Electric All Rights Reserved72

ENGLISH

Adjustment

Turn off all power supplying this equipment before working on or inside the

equipment, and follow lockout/tagout procedures. Always use a properly

rated voltage sensing device to confirm the power is off.

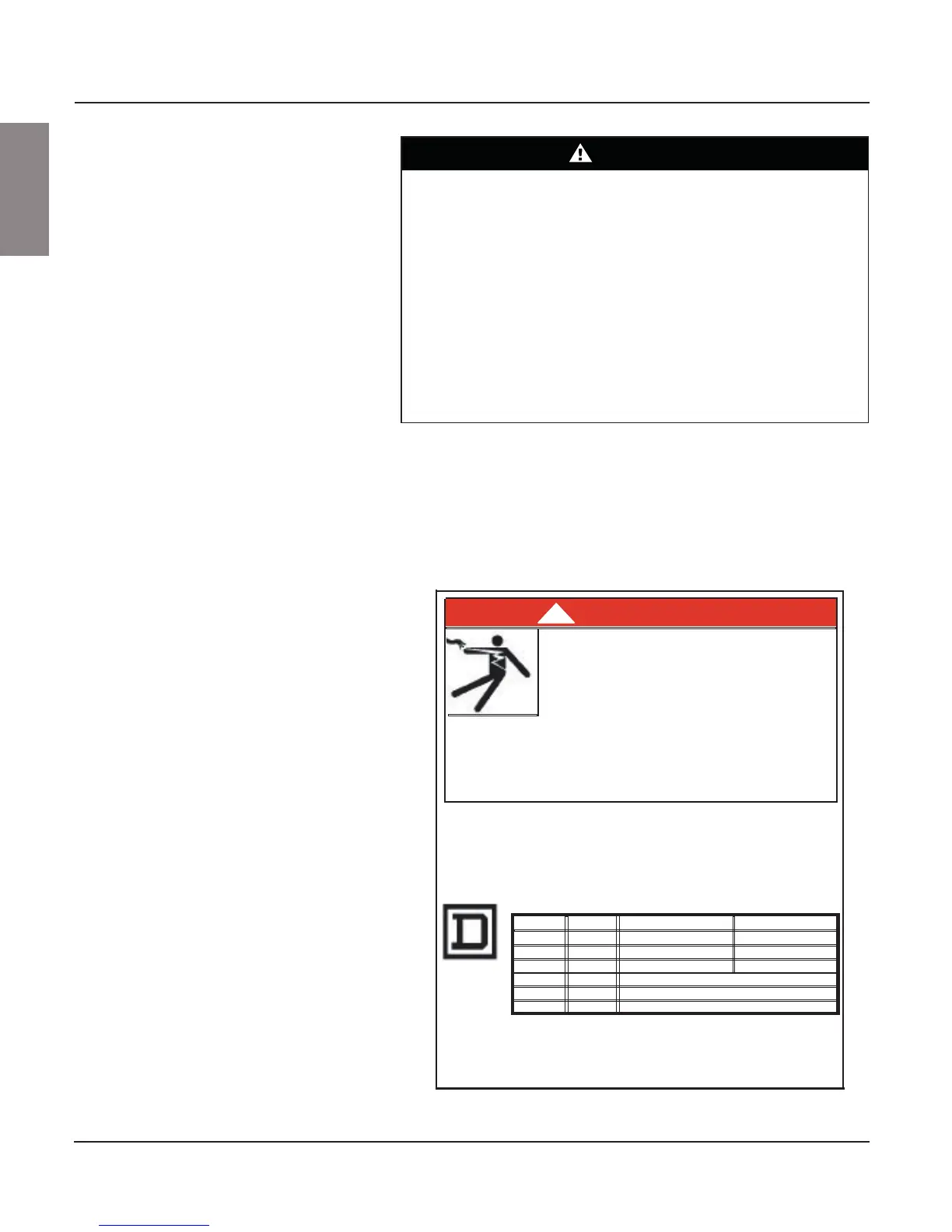

Overload adjustment information is located on a label inside the unit door

(Figure 103) of starter units equipped with the Motor Logic overload relay.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E or CSA Z462.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or inside

equipment.

• Always use a properly rated voltage sensing device to confirm power is

off.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow this instruction will result in death or serious injury.

Figure 103: Unit Adjustment Label

DANGER

Trip current rating is 1.25 times the overload relay's current adjustment dial setting.

Instructions above assume the motor is applied at its rated ambient temperature. For other

conditions, consult the motor manufacturers for current capacity. NOTE: For part winding and

multi-speed applications, use the MFLC of each motor winding as a basis for overload

adjustment.

Trip and alarm contact ratings: NEMA A600 and NEMA P300.

SOLID - STATE OVERLOAD RELAY

CURRENT RANGE:

SIZE 00C 3 - 9A 1.5 - 4.5A (2 PASSES) 1 - 3A (3 PASSES)

SIZE 0

SIZE 1

SIZE 2

SIZE 3

SIZE 4

6 - 18A

9 - 27A

15 - 45A

30 - 90A

45 - 135A

3 - 9A (2 PASSES)

4.5 -13.5A (2 PASSES)

MULTIPLE PASSES NOT AVAILABLE

MULTIPLE PASSES NOT AVAILABLE

MULTIPLE PASSES NOT AVAILABLE

2 - 6A (3 PASSES)

3 - 9A (3 PASSES)

* Passes refer to multiple looping through overload windows.

Failure to follow these instructions will result in death,

serious injury or equipment damage.

Turn off power supplying equipment

before working inside.

For fusible switch starter units, power fuses

must be selected in accordance with Article

430 of the NEC. Class RK5 fuses are

recommended for NEMA rated applications.

HAZARD OF ELECTRIC SHOCK, BURN OR

EXPLOSION

80438-651-01 G

•

REV

OPERATING INSTRUCTIONS;

For continuous-rated motors with

service factors of 1.0, multiply the motor

full-load current (MFLC) by the number of passes through the overload relay's

windows (1,2 or 3) and set the overload relay's current adjustment dial to 90% of this

value. For continuous-rated motors with service factors of 1.15 to 1.25, multiply the

MFLC by the number of passes through the overload relay's windows (1,2 or 3) and

set the overload current adjustment dial to this value.

Use only Class J fuses for Compac™ 6 units.

•

•

SIZE 00B

1.5 - 4.5A

0.75 - 2.25A (2 PASSES)

0.5 - 1.5A (3 PASSES)

Loading...

Loading...