80459-641-01E Model 6 Motor Control Centers

10/2012 Section 13—Circuit Breaker and Fusible Switch Replacement

© 1999–2012 Schneider Electric All Rights Reserved

111

ENGLISH

Section 13—Circuit Breaker

and Fusible Switch

Replacement

For F-frame and K-frame circuit breakers and 100/200 A fusible switches,

Schneider Electric recommends replacing the entire disconnect assembly

instead of replacing the circuit breaker or fusible switch. The disconnect

assembly includes the operator mechanism and the appropriate circuit

breaker or switch. Replacing the entire disconnect assembly requires the

removal of three screws (two from the left side of the assembly and one

inside the back of the assembly). This procedure is much simpler and

quicker than replacing an individual circuit breaker or switch. See Schneider

Electric bulletin Disconnect Assembly Replacement (80439-666-01) for

disconnect assembly installation instructions.

For PowerPact™ H-frame and J-Frame circuit breakers, order a

replacement circuit breaker only. To replace the circuit breaker:

1. Turn off all power supplying this equipment before working on or inside

the equipment, and follow lockout/tagout procedures. Always use a

properly rated voltage sensing device to confirm power is off.

2. Remove the control unit from the MCC. See “Removing the Control Unit”

on page 57.

3. Open the line insulator tabs.

4. Loosen the screw lugs for the line/load cables; detach the cables.

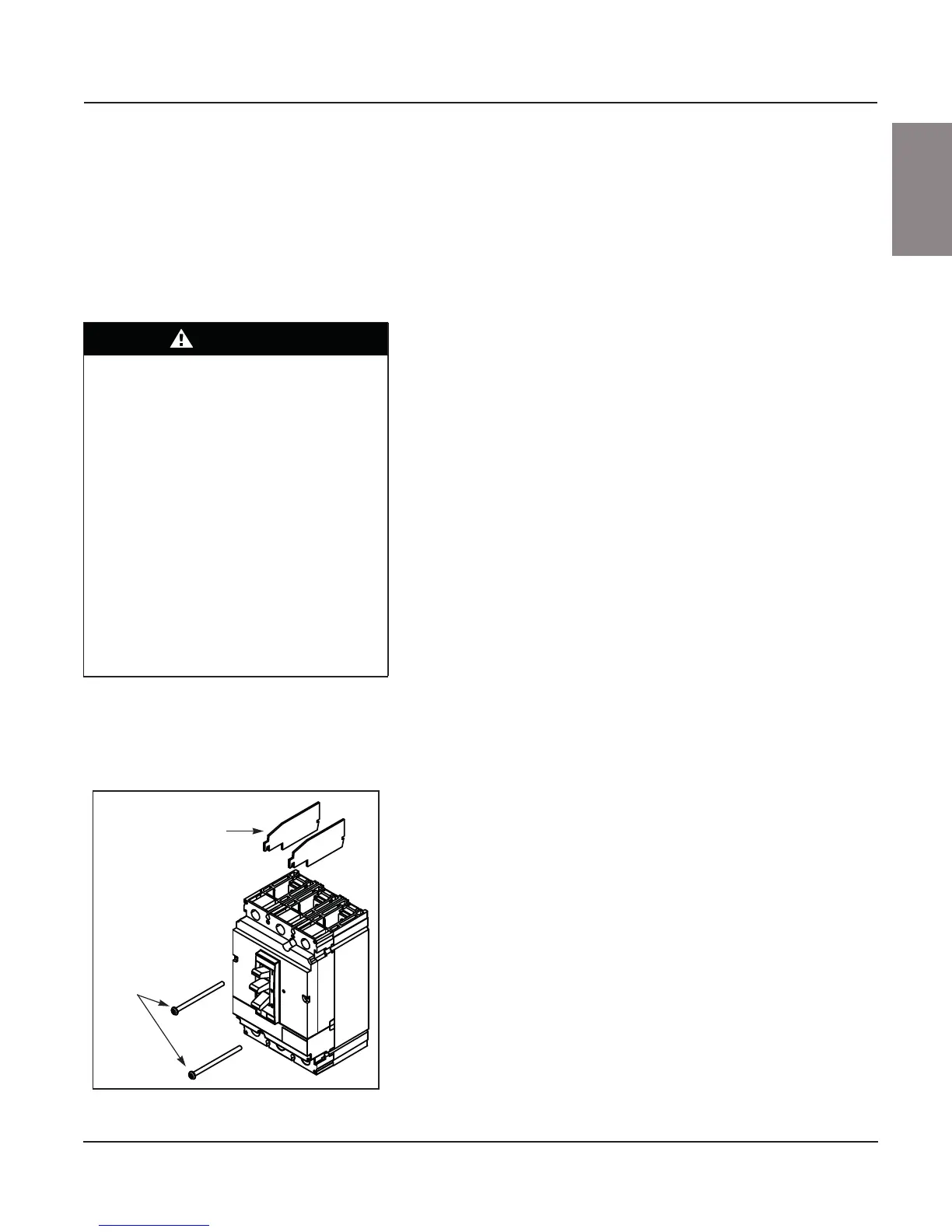

5. Remove the two circuit breaker mounting screws (see Figure 128).

6. Remove the circuit breaker from the unit and then remove the phase

insulators from the breaker (see Figure 128).

7. Unpack the new circuit breaker and reinstall the circuit breaker phase

insulators in the slots provided on the circuit breaker.

8. Place the circuit breaker in the mounting pan, making sure that the line

insulator is in position under the circuit breaker. Secure the circuit

breaker with the two mounting screws provided.

9. Attach the line/load cables to the breaker using the screw lugs removed

in step 4; torque the screw lugs to the value indicated on the circuit

breaker.

10. Close the line insulator tabs.

11. Reinstall the control unit in the MCC. Close and fasten the door.

Always use replacement devices of the same type and rating as the device

being removed. Using a different type of disconnect or one with a different

rating may alter the short circuit ratings of the motor control center.

Contact the MCC Technical Assistance Group (TAG) before installing a

circuit breaker with a different rating. See “Appendix D—Technical Support”

on page 131 for the MCC TAG technical support number.

DANGER

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective

equipment (PPE) and follow safe electrical

work practices. See NFPA 70E or

CSA Z462.

• This equipment must only be installed and

serviced by qualified electrical personnel.

• Turn off all power supplying this equipment

before working on or inside equipment.

• Always use a properly rated voltage sensing

device to confirm power is off.

• Replace all devices, doors, and covers

before turning on power to this equipment.

Failure to follow this instruction will result

in death or serious injury.

Figure 128: Circuit Breaker Replacement

Phase

insulators

Mounting

screws

Loading...

Loading...