Model 6 Motor Control Centers 80459-641-01E

Section 6—Maintaining the MCC 10/2012

© 1999–2012 Schneider Electric All Rights Reserved56

ENGLISH

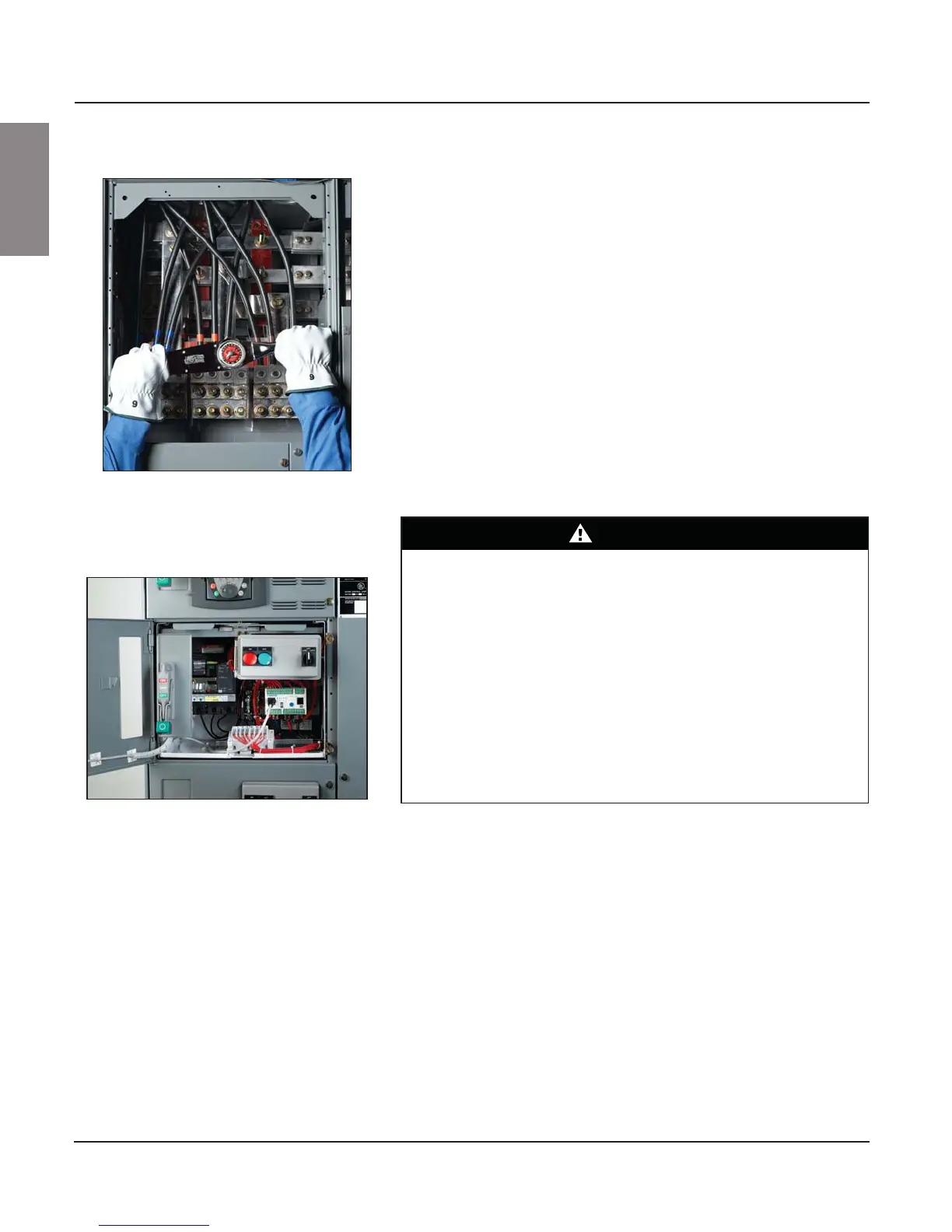

6. Verify that all main lug, circuit breaker, or fusible switch set screws

holding incoming conductors in main lugs are in place and properly

tightened (see Figure 70). Use a torque wrench and a 3/8 in. allen bit to

torque the lug set screws to the appropriate value (see “Cable

Connection Torque Values” on 51).

7. Inspect all insulators, braces, and barriers; replace any that show signs

of arcing damage, tracking, excessive heat, or cracking.

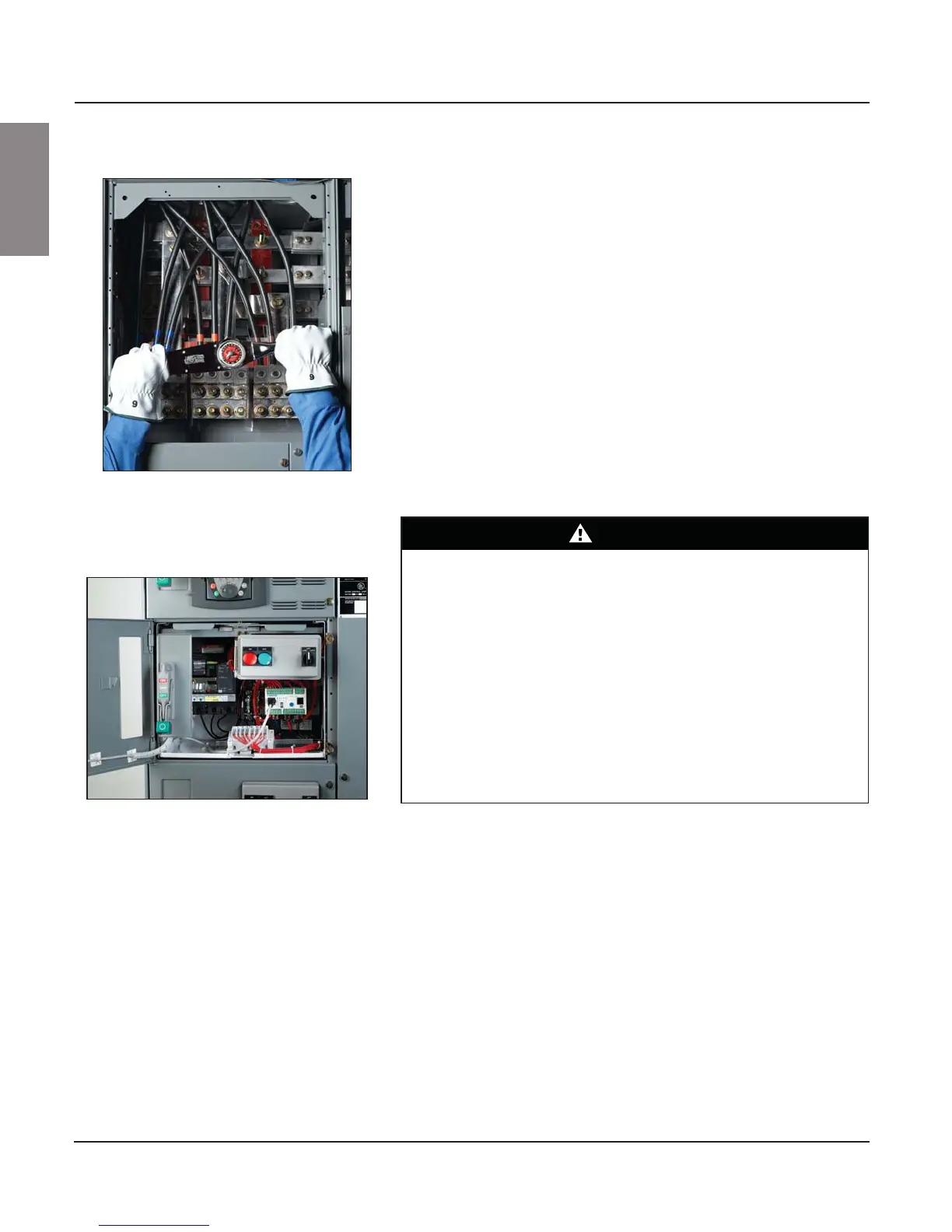

Maintaining the Control Unit

Perform maintenance on control units at least annually, or more frequently if

indicated by service conditions and your established maintenance policy.

During installation, locate and tighten any connections that have become

loose during shipment and handling, using the following procedures. If the

control unit (see Figure 71) is being removed from the MCC for

maintenance, start with “Removing the Control Unit” beginning on page 57.

If maintenance is performed with the control unit installed, start with “Circuit

Breaker or Disconnect Switch” on page 63.

Figure 70: Main Lug Compartment Torque

Connection

Figure 71: Control Unit

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E or CSA Z462.

• This equipment must only be installed and serviced by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or inside

equipment.

• Always use a properly rated voltage sensing device to confirm power is

off.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow this instruction will result in death or serious injury.

Loading...

Loading...