38

Troubleshooting

7.3 Troubleshooting the pH Sensor

Clean the sensor using the procedure described in section 6.2 on page 34. If the

measuring system cannot be calibrated after cleaning, replace the standard cell solution

and salt bridge (see section 6.2.1 on page 35) and try calibrating again. If the measuring

system still cannot be calibrated, check the sensor operation.

Some simple tests using the sc100 or a multimeter and two pH buffers will determine if the

pH sensor is operating properly. The use of pH 7 and pH 4 buffers is preferred but pH 10

can be used in place of pH 4 if it more closely covers the measurement range of interest.

Determine if the sensor has integral digital electronics or uses an external digital gateway.

If the sensor uses a digital gateway, it will be hard-wired to the gateway through terminal

connections inside the digital gateway enclosure. If the sensor uses the digital gateway

and therefore does not have integral digital electronics, proceed with section 7.3.1. If the

sensor has integral digital electronics, move to section 7.3.2 on page 39.

7.3.1 Troubleshooting a pH Sensor without Integral Digital Electronics

1. Disconnect the red, green, yellow, and black sensor wires from the digital gateway.

2. Place the sensor in a pH 7 buffer. Before continuing, allow the temperatures of the

sensor and buffer to equalize to approximately 25 °C (70 °F).

3. Verify that the sensor temperature element (300 ohm thermistor) is operating properly

by measuring the resistance between the yellow and black wires. The reading should

be between 250 and 350 ohms at approximately 25 °C (70 °F).

4. Reconnect the yellow and black wires.

5. Connect the multimeter (+) lead to the red wire and (–) lead to the green wire. With the

sensor in the pH 7 buffer, measure the dc millivolts. The sensor offset reading should

be within the factory-specified limits of –50 and +50 mV. If it is, record the millivolt

value reading and continue with step 6. If the reading is outside these limits,

discontinue this test and contact Technical Support.

6. With the multimeter still connected, rinse the sensor with water and place it in either

pH 4 or pH 10 buffer. Allow the temperatures of the sensor and buffer to equalize to

approximately 25 °C (70 °F) then measure the sensor span reading as shown in Table

8 and Table 9 on page 39.

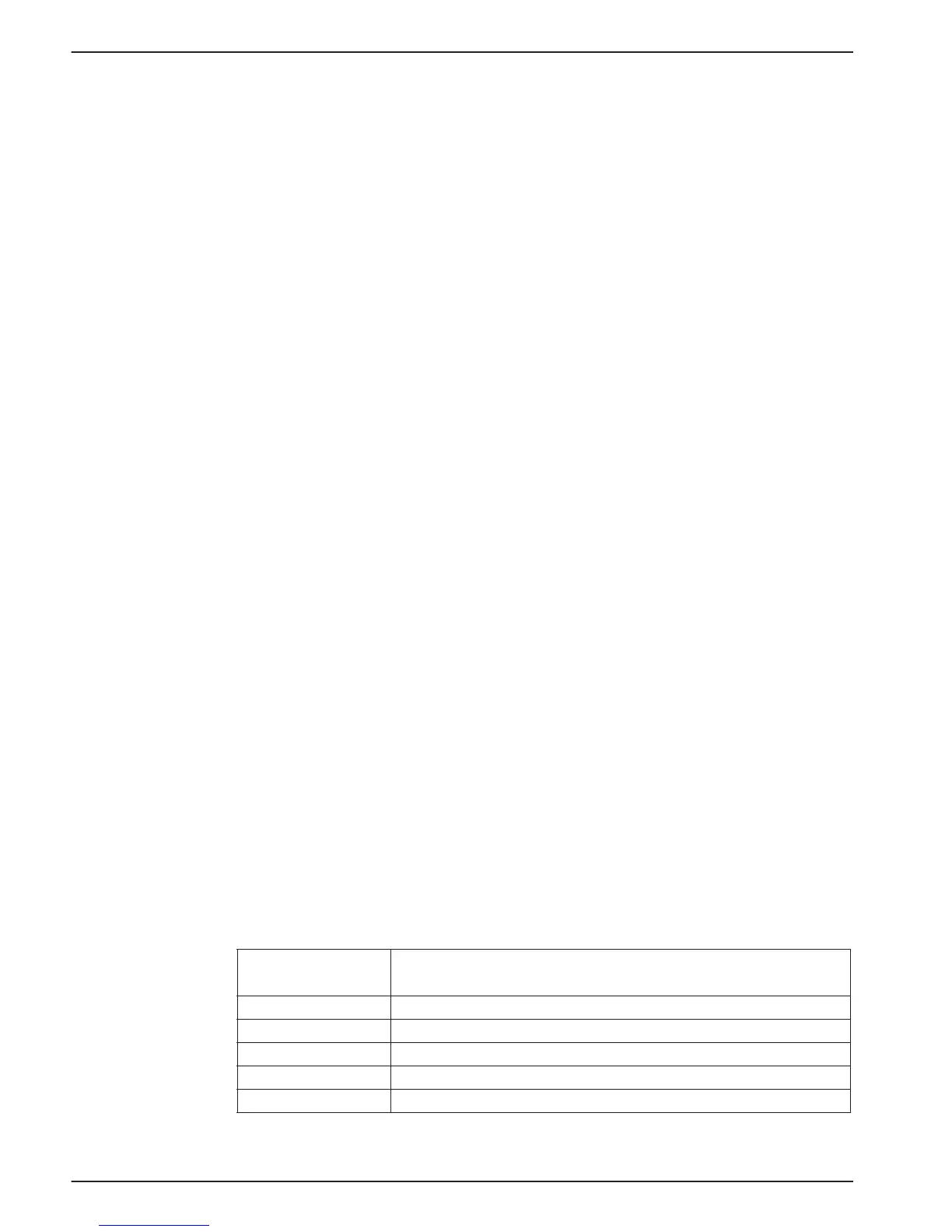

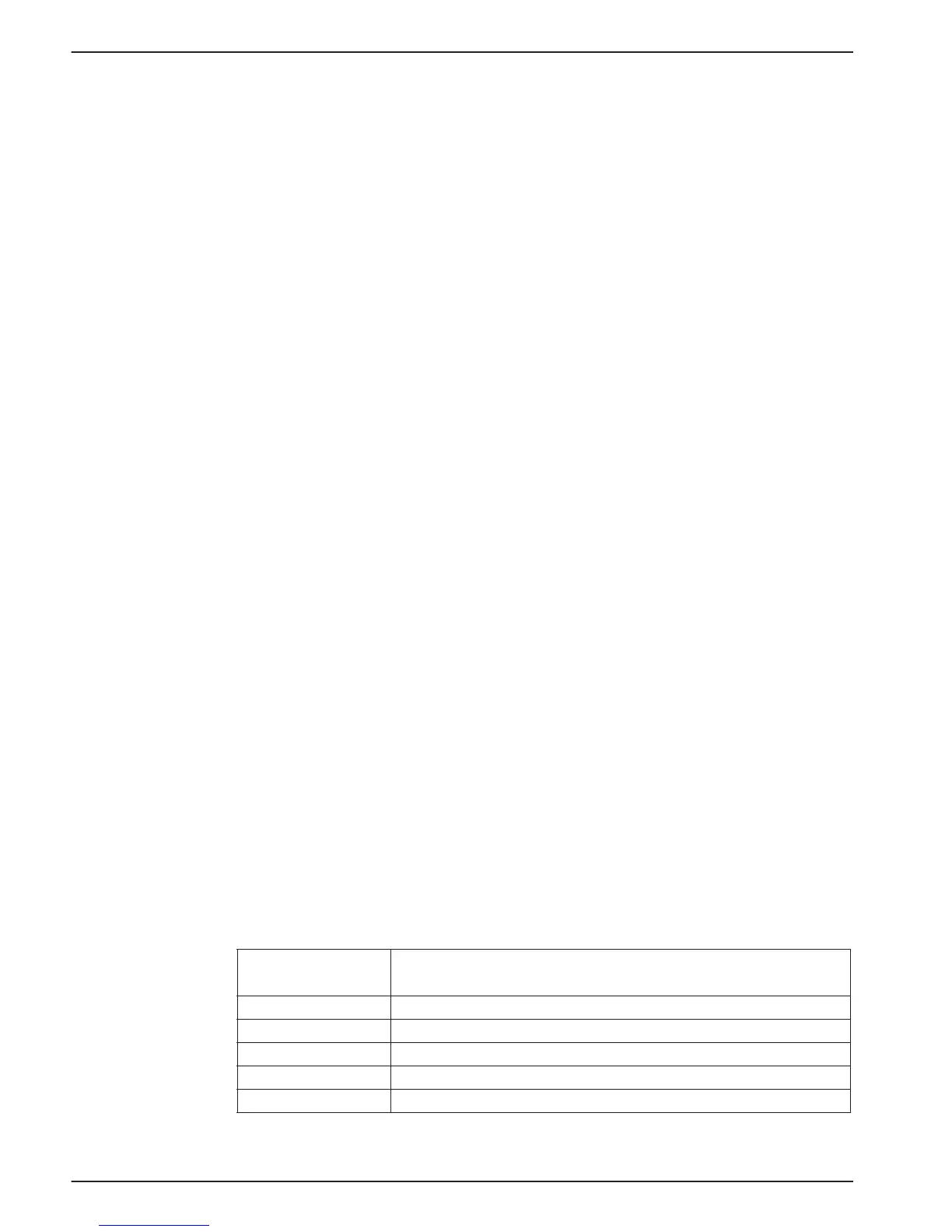

Span Reading in pH 4 Buffer

With the sensor in pH 4 buffer, the sensor span reading should be at least +160 mV more

than the offset reading taken in step 5.

Table 8 Typical Span Reading Examples (pH 4 buffer)

Offset Reading

(in pH 7 buffer)

Span Reading (in pH 4 buffer)

–50 mV +110 mV

–25 mV +135 mV

0 mV +160 mV

+25 mV +185 mV

+50 mV +210 mV

Loading...

Loading...