Intel

®

EP80579 Integrated Processor Product Line May 2010

Order Number: 320068-005US 138

PCI Express* Interface—Intel

®

EP80579 Integrated Processor Product Line

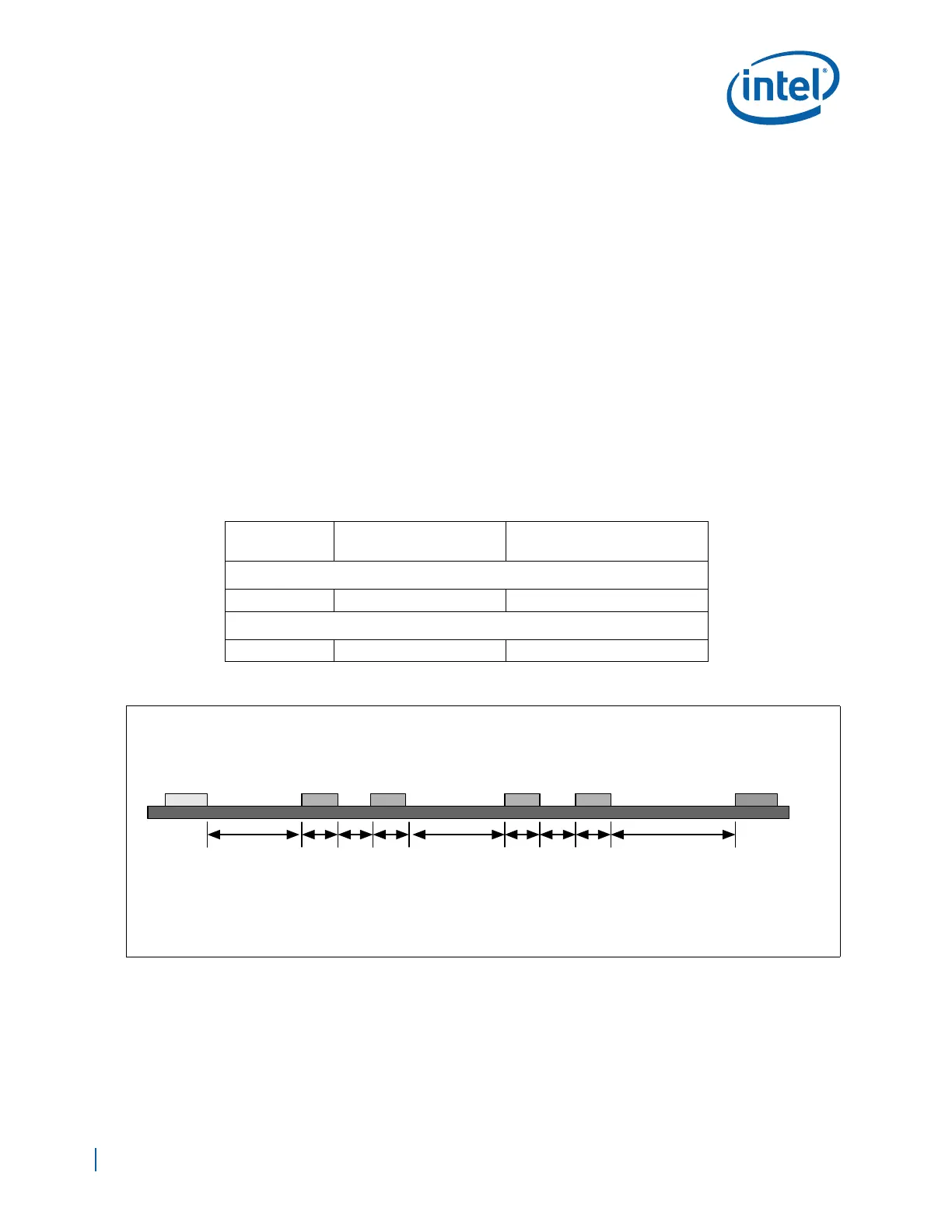

Follow the specified stackup in Figure TBD to avoid frequency-dependent loss effects

that may occur at PCI Express edge rates. If the dielectric characteristics are different

from those specified in the stackup (TBD), the solution space presented in this section

may not apply. This inaccuracy may happen even if the trace widths are adjusted to

meet the specified impedance targets because the attenuation of high frequency

components is a function of the trace width, thickness, and dielectric characteristics.

Simulate and validate any design that deviates from the specified stackup.

10.1.2 Impedance Requirements

The tables in this section show the required geometry for the stripline and microstrip

PCI Express differential signals.

Stripline traces are routed on inner layers. Signals travel slower on stripline traces than

on microstrip traces. They have a very low FEXT and very low dispersion. Table 48

indicates the differential impedance and trace width used in routing stripline signals.

Microstrip traces are routed on the outer layers. Signals travel a bit faster on the

microstrip traces compared to stripline traces. They have significant FEXT and notable

frequency and mode dependence on velocity. Table 48 indicates the differential

impedance and trace width used in routing microstrip signals.

Table 48. Trace Width/Impedance Requirement for Stripline and Microstrip Layers

Trace Width Nominal Trace Spacing

Nominal Trace Impedance

(Zo)

Stripline Layers (3 or 8)

4.5 mils 5.5 mils edge-to-edge 90 Ω ±10% (Differential)

Microstrip Layers (1 or 10)

4.75 mils 5.25 mils edge-to-edge 90 Ω ±10% (Differential)

Figure 87. Recommended PCI Express Stripline Trace Width/Spacing

Differential

Pair

Distances in Mils

Non-

Interface

Signal

Non-

Interface

Signal

Differential

Pair

18 or 3x dielectric

thickness

18 or 3x

dielectric

thickness

18 or 3x dielectric

thickness

4.5

5.5

4.5 4.5 4.5

5.5

Loading...

Loading...