214603 80 Revision A

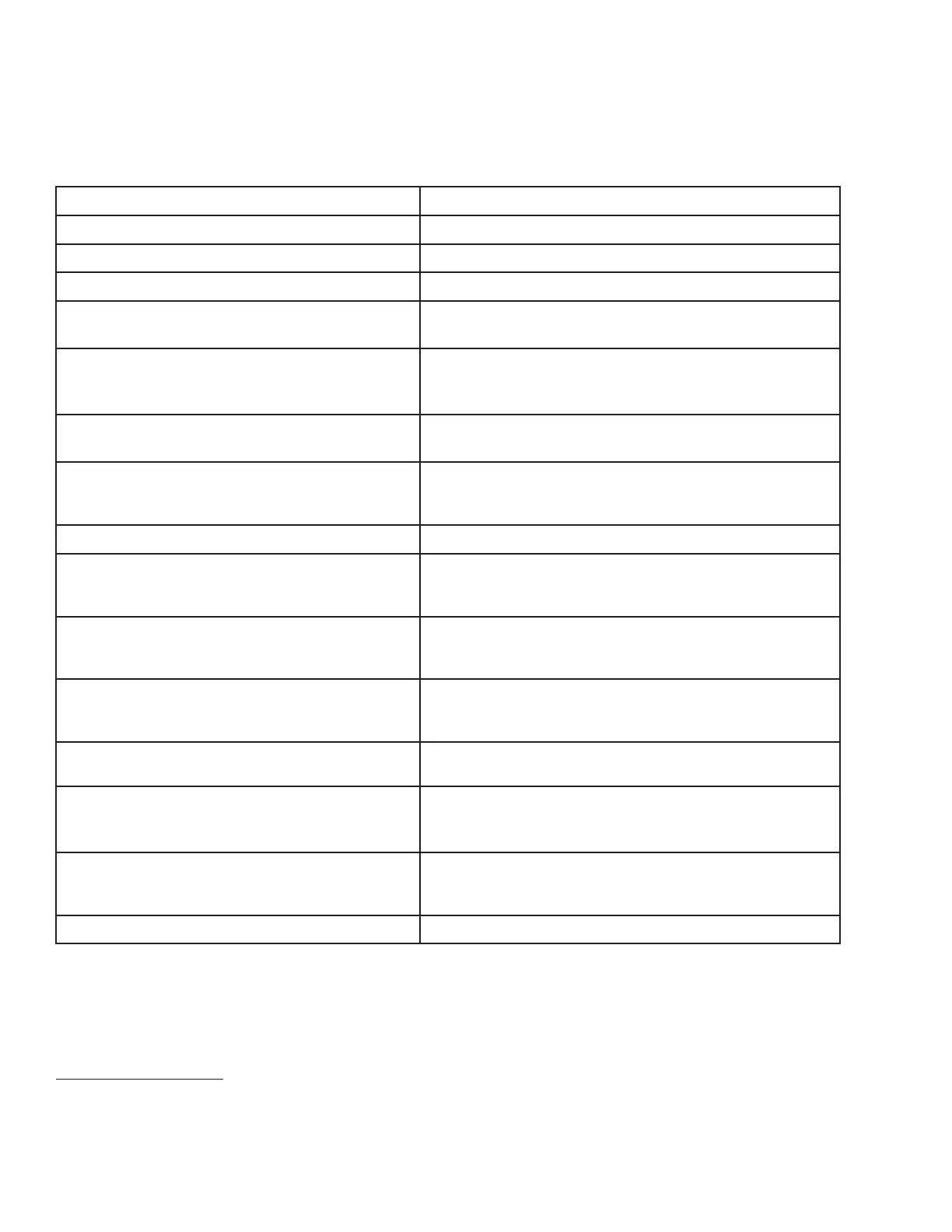

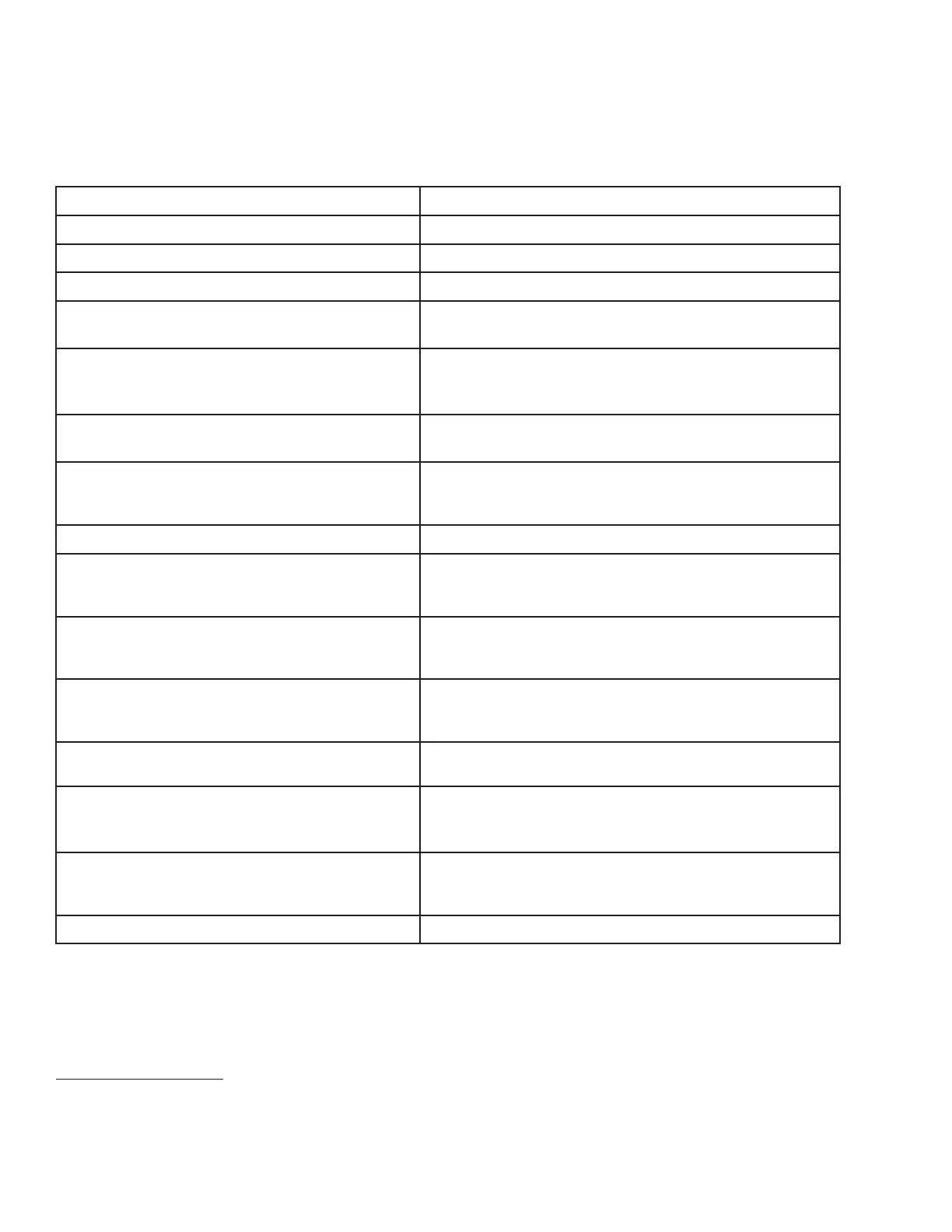

Cab-Forward, Engine Running, Header Engaged, Auger Header Index Switch OFF

Scroll through display with cab display module (CDM) switch or ground speed lever (GSL) switch.

Display (Lower or Upper Line)

Description

#####.# ENGINE HRS

Total engine operating time

#####.# UNIT HRS

Total windrower operating time

#####.# HEADER HRS

Total header operating time

##.# ACRES/HOUR

##.# HECTARES/HOUR (if Metric)

Actual cutting rate in acres (hectares)/hour

###.# SUB ACRES

###.# SUB HECTARES (if Metric)

Area cut since last reset; to reset, display SUB ACRES on

lower line, and hold down PROGRAM switch until display

resets (5 to 7 seconds)

###### TOTAL ACRES

###### TOTAL HECT (if Metric)

Total area cut by machine

##.## REEL RPM

##.## REEL SENSOR

Reel rotational speed

Sensor disabled. RPM and SENSOR alternate at 1 second

intervals

##.# AUGER SPEED Auger rotational speed (4.7–9.9)

#### KNIFE SPEED

#### KNIFE SENSOR

Knife speed in strokes per minute

Sensor disabled. SPEED and SENSOR alternate at

1 second intervals

##.# HEADER HEIGHT

##.# HEADER SENSOR

Distance setting (00.0–10.0) between cutterbar and ground

Sensor disabled. HEIGHT and SENSOR alternate at

1 second intervals.

##.# HEADER ANGLE

##.# HEADER SENSOR

Angle setting (00.0–10.0) header relative to ground

Sensor disabled. ANGLE and SENSOR alternate at

1 second intervals

##.# L FLOAT R ##.#

FLOAT SENS DISABLED

Left and right float setting (0.0–10.0)

Sensor disabled

LOAD|■■■■| | ####

Bar graph representing hydraulic operating pressure. Full

scale is preprogrammed overload pressure (2500–

5000 psi). If sensor disabled, LOAD does not display

6

### °C or F HYD OIL TEMP

### °C or F HYD TEMP

Hydraulic oil temperature

Sensor disabled. TEMP and SENSOR alternate at

1 second intervals

##.# VOLTS

Engine electrical system operating voltage

OPERATOR’S STATION

6. The LOAD sensor to monitor knife/conditioner circuit pressure is optional. To monitor reel/auger circuit

pressure, relocate sensor as per kit instruction MD #169031, which is available through your Dealer.

Loading...

Loading...