214603 349 Revision A

5.9 Electrical System

5.9.1 Preventing Electrical System Damage

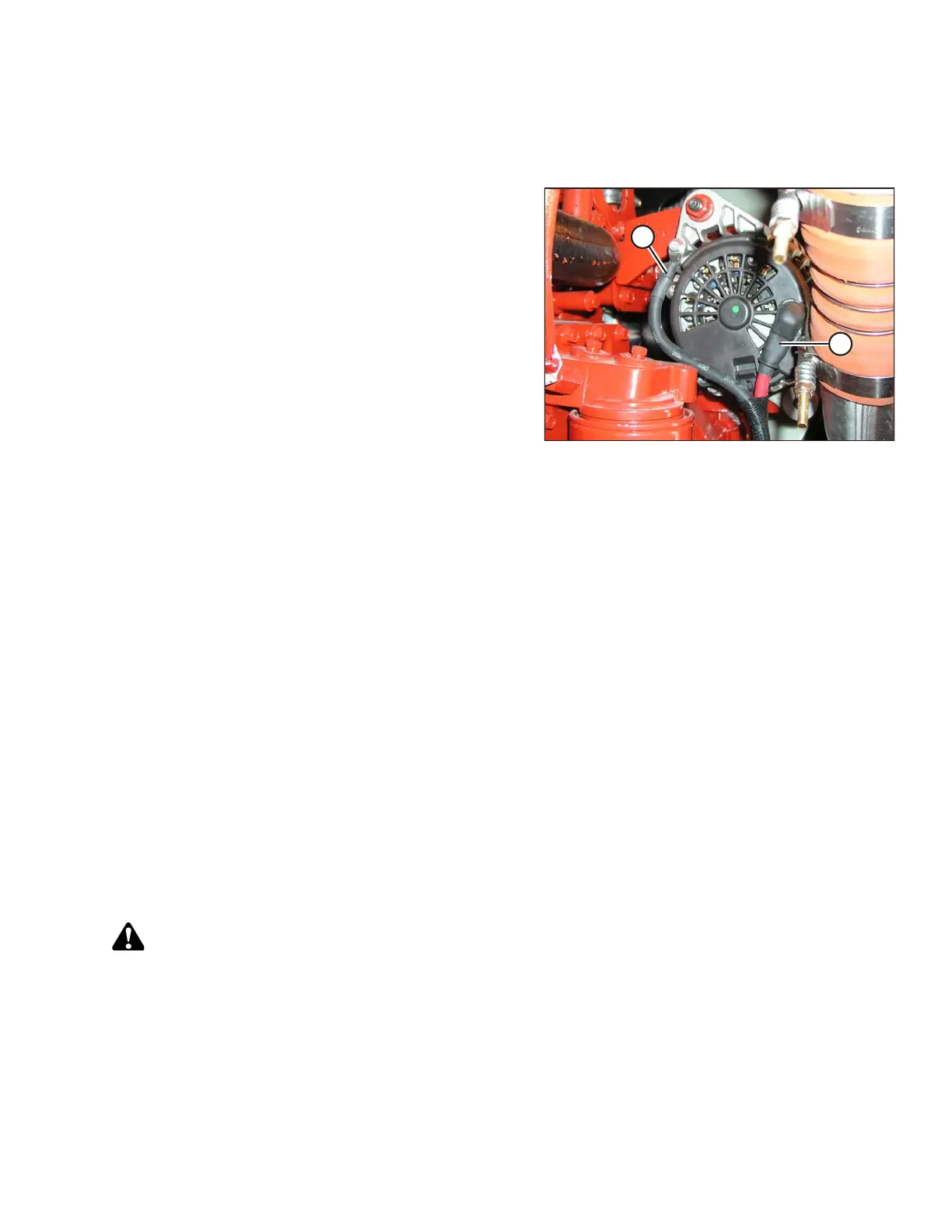

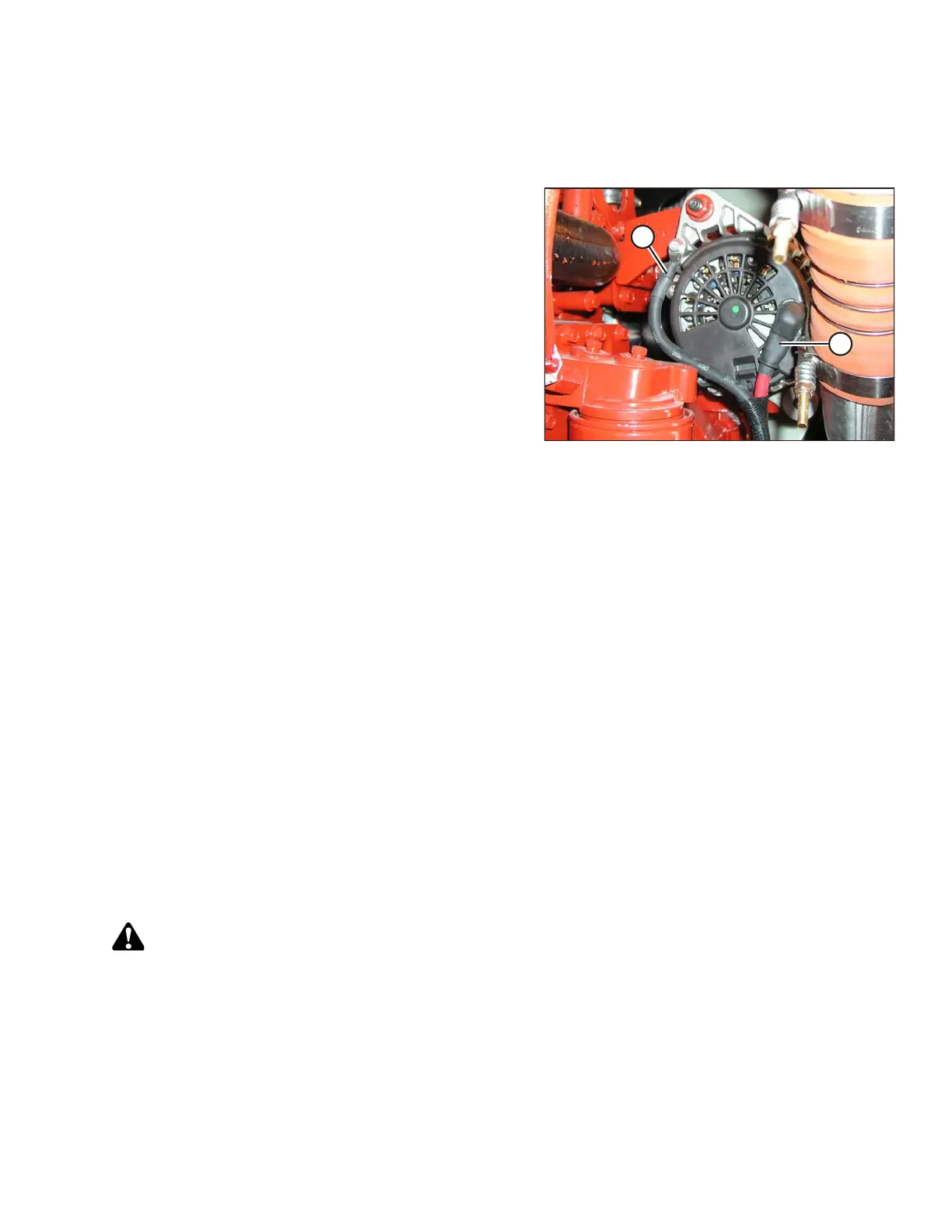

Figure 5.113: Alternator

A - Negative Terminal B - Positive Terminal

To prevent electrical system damage, take the following

precautions:

• Carefully observe polarity when attaching

booster battery.

• Do NOT short across battery or alternator terminals, or

allow battery positive (+) cable or alternator wire to

become grounded.

• Be sure alternator connections are correct before cables

are connected to battery.

• When welding on any part of the machine, disconnect

battery cables and alternator wire. Refer to 1.8 Welding

Precautions, page 9.

• Always disconnect battery ground cable when working

with the alternator or regulator.

• Never attempt to polarize alternator or regulator.

• If wires are disconnected from the alternator, ensure that

terminals (A) and (B) are connected properly.

• Never ground the alternator field terminal or field.

• Never connect or disconnect alternator or regulator

wires with battery connected or alternator operating.

• Always disconnect cables from the battery when using a

charger to charge battery in windrower.

• Ensure all cables are securely connected before

operating engine.

• To avoid damage to circuit boards by static electricity,

disconnect negative battery terminal when replacing

electronic control modules. Additionally, when handling

electronic control modules, avoid touching the connector

pins directly.

5.9.2 Battery

Maintaining Batteries

CAUTION

Do NOT attempt to service battery unless you have the proper equipment and experience to perform the

job. Have it done by a qualified Dealer.

• Check battery charge once a year, or more often if operating in cold weather. Hydrometer readings should be

1.260 to 1.300. Readings below 1.250 indicate charging is required. Refer to Charging the Batteries, page 350.

Add electrolyte if necessary. Refer to Adding Electrolyte to the Battery, page 353.

• Keep batteries clean by wiping with a damp cloth.

MAINTENANCE AND SERVICING

Loading...

Loading...