214603 395 Revision A

open at the relief setting. Otherwise, reduce the ground speed to maintain the correct system load and header drive

operation.

The overload pressure is programmed into the CDM when inputting the header parameters. Refer to 3.19.6 Cab

Display Module (CDM) Configuration, page 90 and Table 5.3, page 395 for suggested settings.

If lift and drive capacity problems develop, the pressure relief valve may require adjusting. Contact your

MacDon Dealer.

Table 5.3 Relief Valve and Overload Settings

Header Model

Application/System

Windrower Differential Relief

Setting

(Header Attached)

kPa (psi)

Suggested Overload Warning

Setting

kPa (psi)

R80 and R85 Disc Pressure

37,921 (5500) 37,232 (5400)

D60, D65, and

A40D

Reel/Draper Pressure 19,995 (2900) 19,995 (2900)

Knife/Conditioner

Pressure

27,579 (4000) 27,579 (4000)

Flow Control Blocks

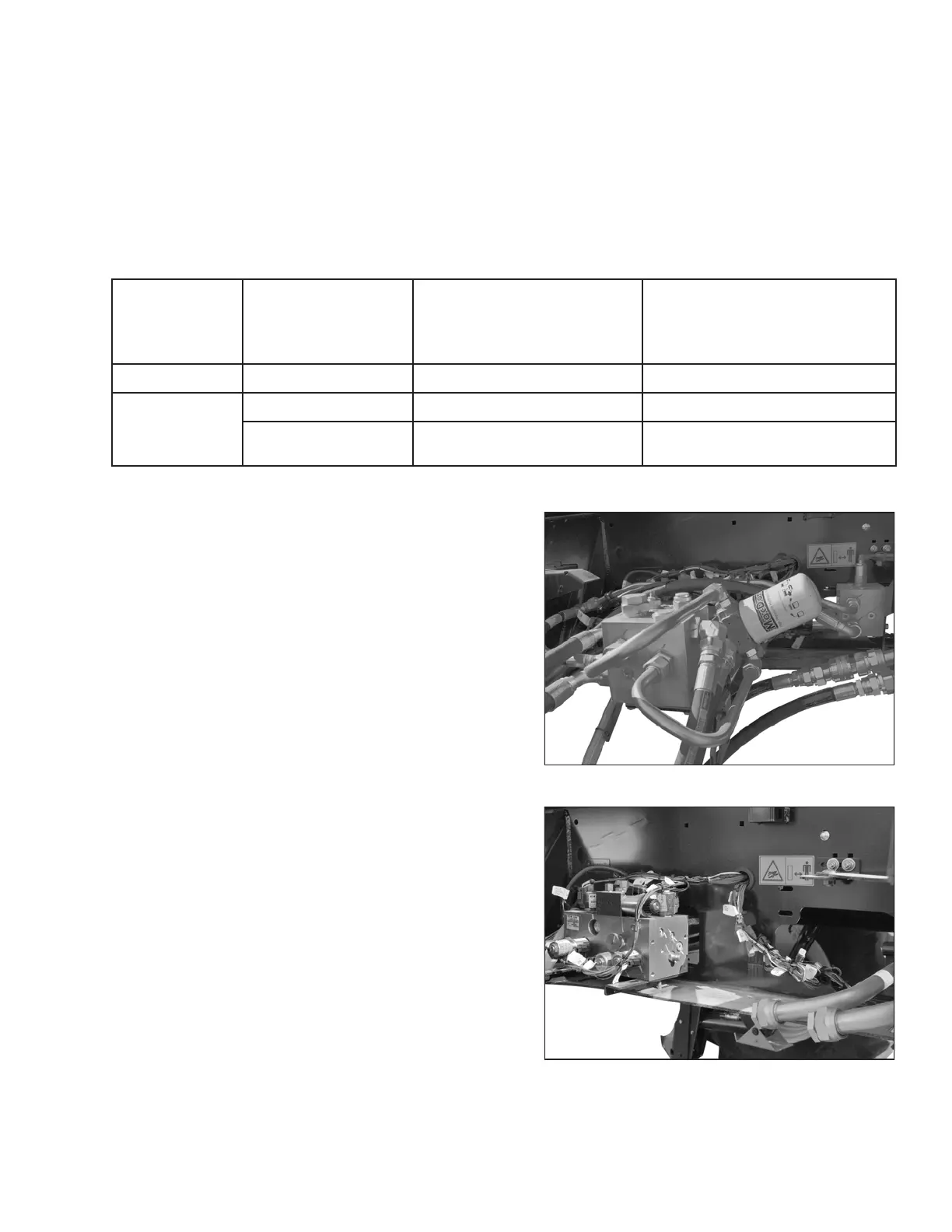

Figure 5.197: Draper Header Hydraulics

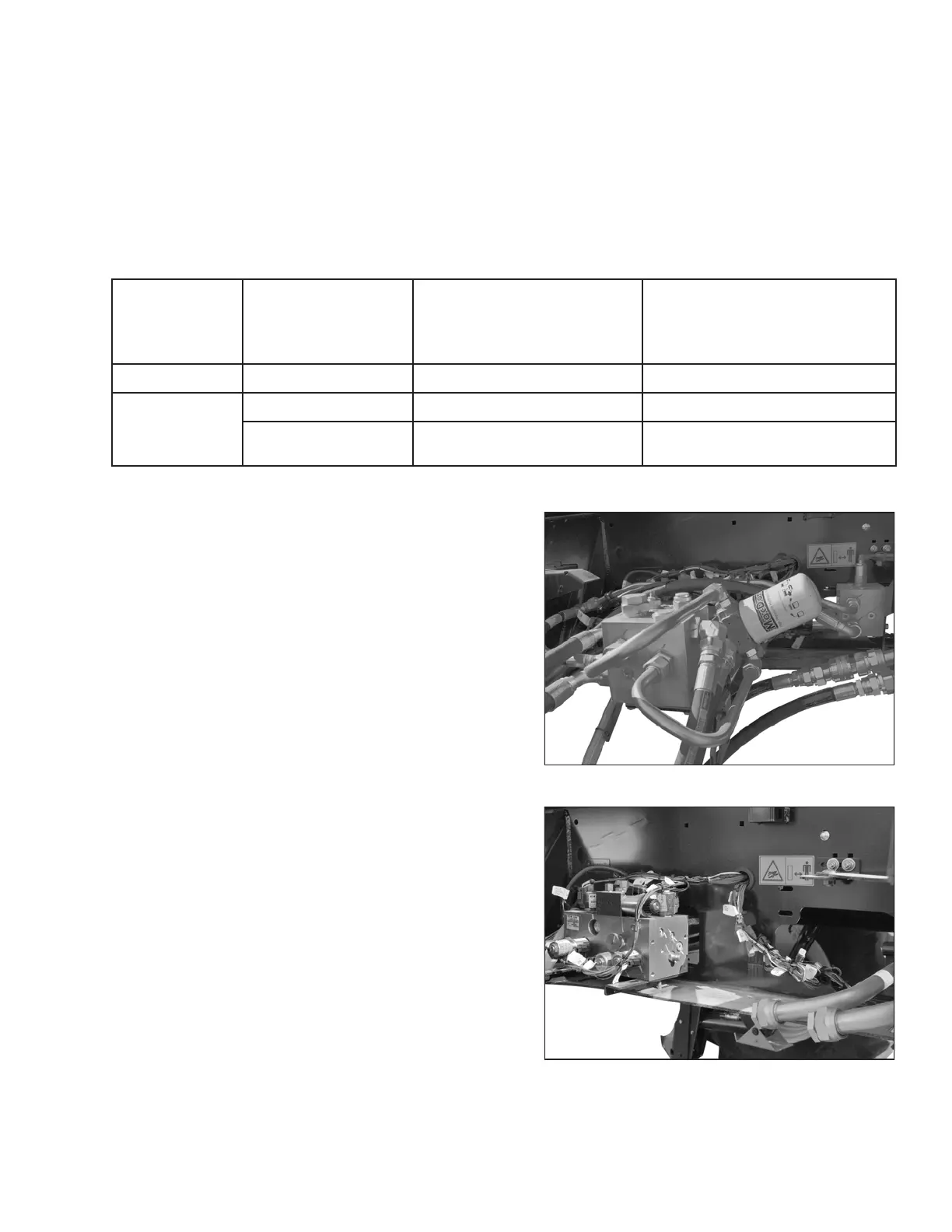

Two hydraulic valve blocks with multiple cartridges are used

for the various windrower functions and are controlled by

the windrower control module (WCM) according to the

inputs from the Operator. The valve blocks are located

behind the left cab-forward side platform.

The valve blocks do not require any scheduled

maintenance other than to check for leaking fittings or loose

electrical connections. If service is required, contact your

MacDon Dealer.

Figure 5.198: Rotary Disc Header Hydraulics

MAINTENANCE AND SERVICING

Loading...

Loading...