214603 205 Revision A

Reversing the Header

NOTE:

The optional hydraulic reversing kit must be installed for auger headers. It is standard for rotary disc headers.

The optional hydraulic reversing kit allows the following:

• Reverses reel, auger, knife, and conditioner drives on A Series auger headers

• Reverses the entire header drive on R Series rotary disc headers

Reverse the header as follows:

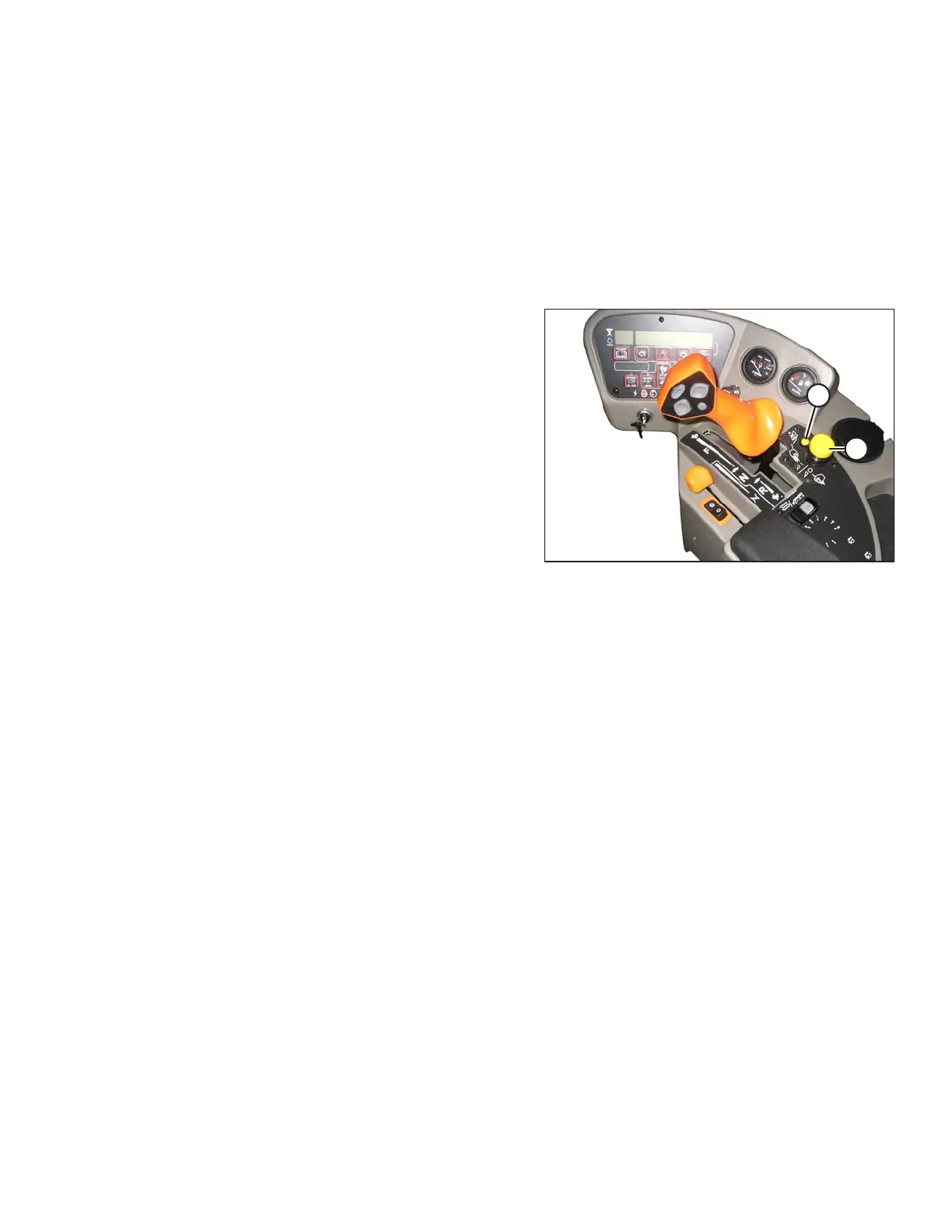

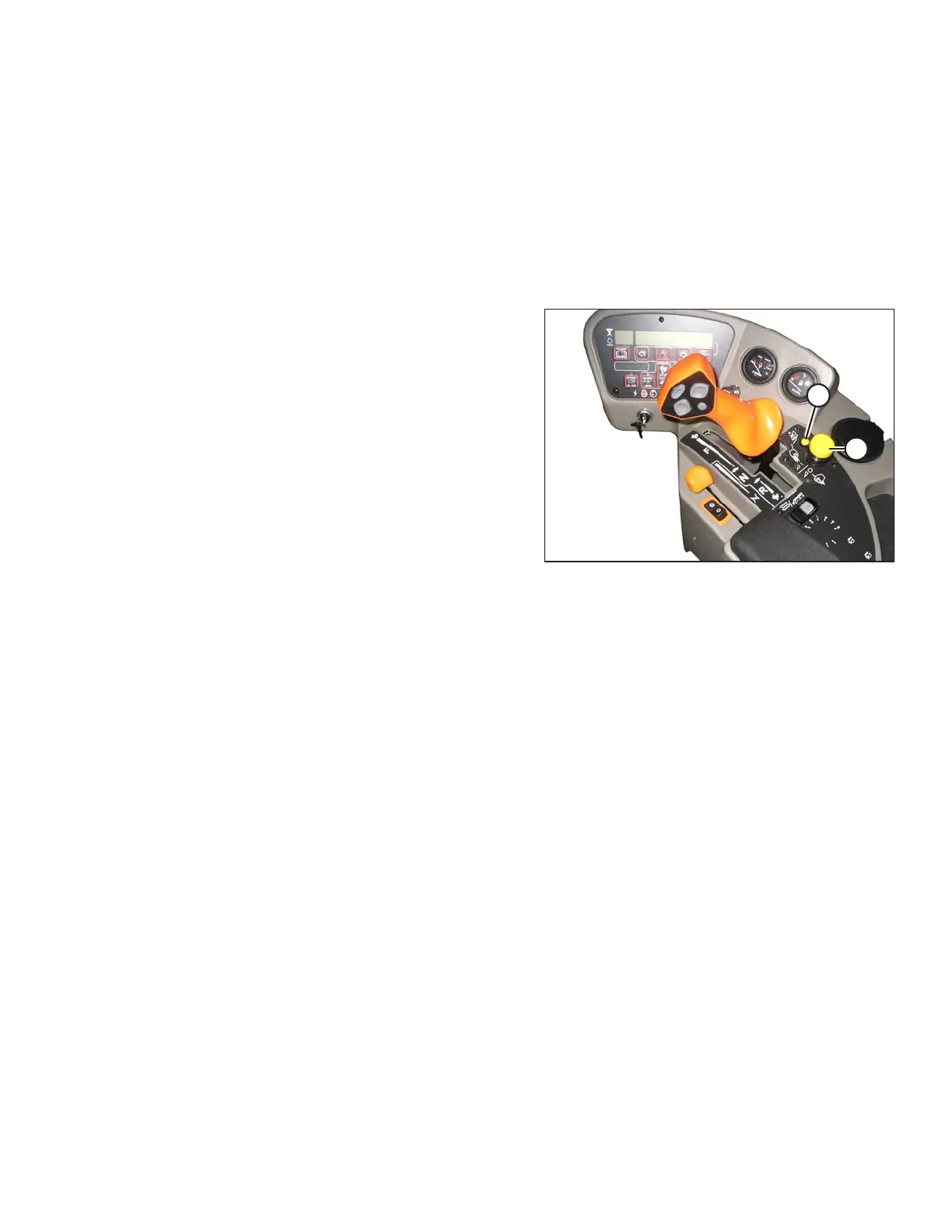

Figure 4.82: Operator Console

1. Push down and hold HEADER DRIVE REVERSE

button (A) and pull up the HEADER DRIVE switch (B).

2. CDM will display HEADER REVERSE.

3. Release REVERSE button (A) to stop header.

4. Push down the HEADER DRIVE switch (B) to OFF, so

that it can be restarted.

NOTE:

To engage header drive, push down, and pull up

HEADER DRIVE knob.

4.4.5 Adjusting Header Angle

Header angle is defined as the angle between the ground and the drapers/cutterbar. It is adjustable to

accommodate crop conditions and/or soil type.

Refer to the appropriate header operator’s manual for the range of adjustment and recommended settings for your

particular header.

The header angle can be hydraulically adjusted from the cab without shutting down the windrower when the

windrower is equipped with the hydraulic center-link. A readout on the cab display module (CDM) allows you to

establish settings for each crop condition.

IMPORTANT:

• Changing header angle will affect float slightly because it has the effect of making the header lighter or heavier.

• To prevent excessive guard breakage when conditions are not suited to heavier float (e.g., rocky or wet), do

NOT use the TILT CONTROL. Instead, use the HEADER HEIGHT switch.

OPERATION

Loading...

Loading...