GBC AdvancedPunch Pro 11/07/2018 RAPS

2-46

5 MOTOR CHECKS

RAP 5.1 Checking Stepper Motors

Use this RAP to check Stepper Motors.

1. Open the front the door and insert an Interlock Cheater into the

Punch Door interlock Switch SW4 (PL 2.2).

WARNING

Moving Parts, keep hands clear of nips and the belts when

the Interlock Cheater is inserted. See Section 0, page vii

for other languages.

2. For motors M1, M2, M3, M4, M6, M7, and M8; do GP 6.2.11 Motors

Procedure to check that the corresponding nip rollers turn (check

Drive and idler Rollers, see PL 3.6 for the identifying the motors.

For Motor M5, do GP 6.2.12 FUNCTION TESTS Procedure (Aligner

Test).

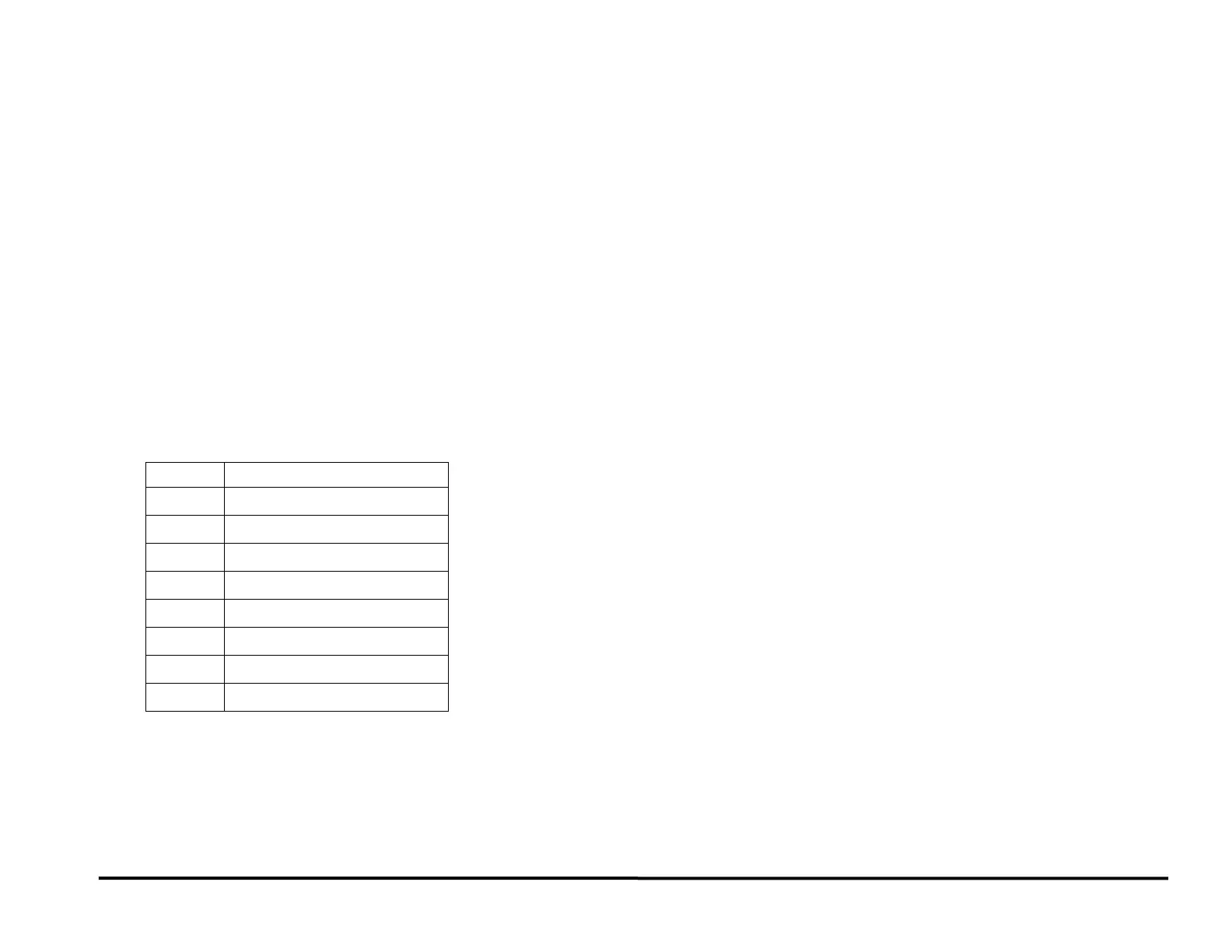

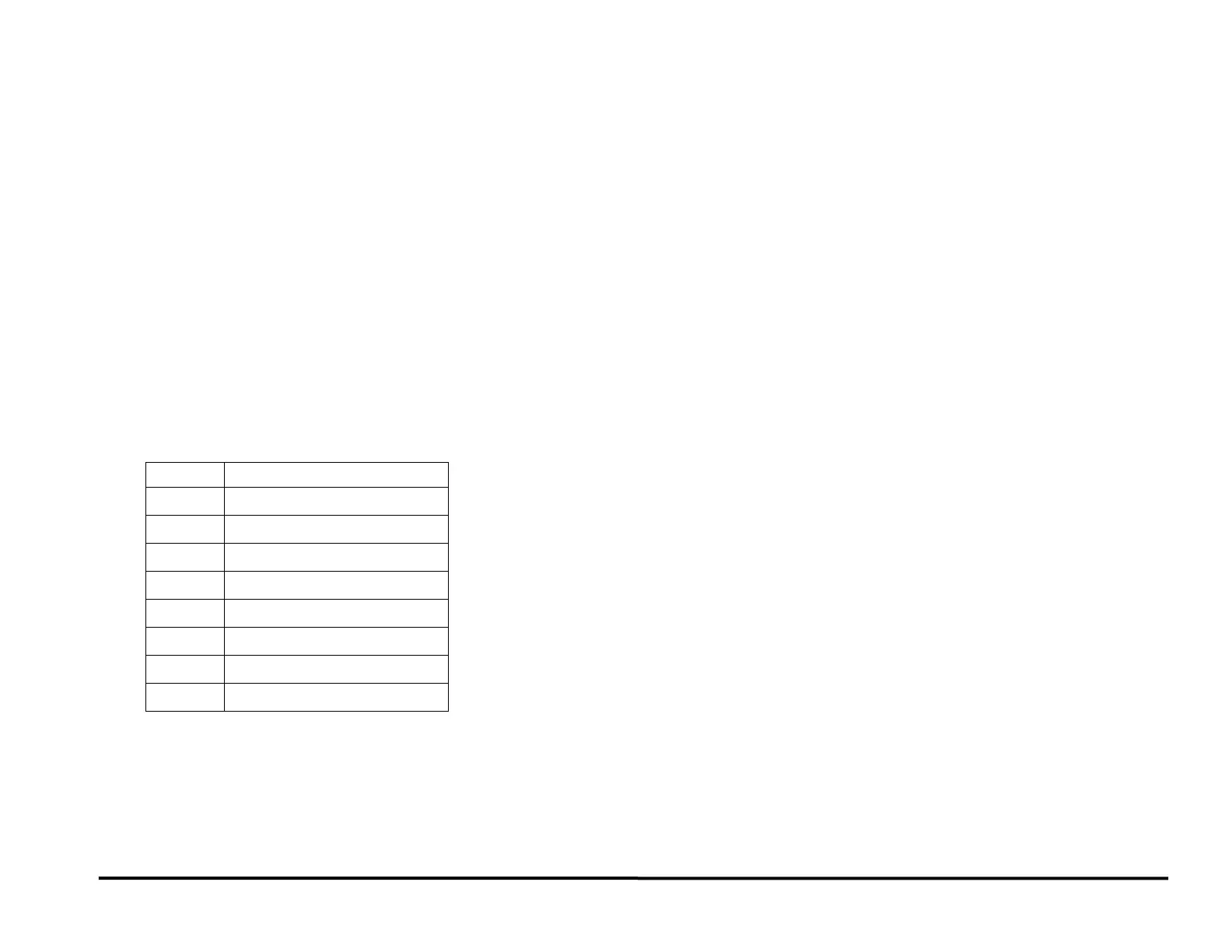

The table below identifies the nip rollers driven by the corresponding

motors:

M1 N2, N3 and N4

M2 N5

M3 N6- Front side steering roller

M4 N7- Rear side steering roller

M5 Alignment Carriage

M6 N8, N9

M7 N10

M8 N1, N11, N12, N13, N14

3. Do REP 1.6 to remove the Rear Cover.

4. If you are troubleshooting M3 or M4 or M5, do the below step, for

other motors directly go to Step 5.

All the below connections are explained in detail in REP3.1 Punch

module Removal/Installation.

M3- Make sure the connector for M3 is inserted into the header at the

back of the punch module.

M4- Make sure the connector for M3 is inserted into the header at the

back of the punch module.

M5- Make sure the connector from M5 stepper motor is inserted into

the driver board for motor M5.

All the connectors are securely connected.

Yes- Go to Step 5; No- Make the connection and resume operation

5. For the motor in question, make sure three connectors at the Stepper

Driver board (J1, J2 and J3) and two connectors at the Main Control

Board are inserted firmly (see Section 7 Wiring)

J17 and J16 for M3, M4 and M5

J17 and J15 for M6, M7 and M8

J17 and J14 for M1 and M2

All the connectors are securely connected.

Yes- Go to Step 5; No- Make the connection and resume operation

6. Inspect the timing belt for the correspond motor drive- GP 6.21 Timing

Belt Inspection. Follow the procedure to inspect the belts and replace

if necessary (REP 2.21).

Note: If the timing belt of motor M5 is damaged (PL 5.2), do REP 3.7

to replace the entire Alignment Carriage Sub Assembly (PL 5.3).

For M5 Alignment Stepper Motor- Inspect the open ended belt in

Alignment carriage Sub assembly (PL 5.3). If it is damaged, replace

the Alignment Carriage sub assembly (REP 3.7)

All timing belts are okay

Yes- Go to Step 6; No- Replace the faulty belt and resume operation

7. Check the tightness of the set screw of pulleys on the stepper motor

shaft (Stepper and Mount assembly PL 3.6). Also check the set

screws/ coiled spring pins for all the pulleys (PL 5.3) that are driven

by the stepper motor in question.

All the set screws are secured tightly

Yes- Go to Step 7;

No- Tighten the loose set screw and resume operation

8. For the motor in question, check the DIP switch settings for the

corresponding Driver Board (see REP 2.26).

All the DIP switch setting are correct

Yes- Go to Step 8; No- Correct the DIP switch and resume operation.

Loading...

Loading...