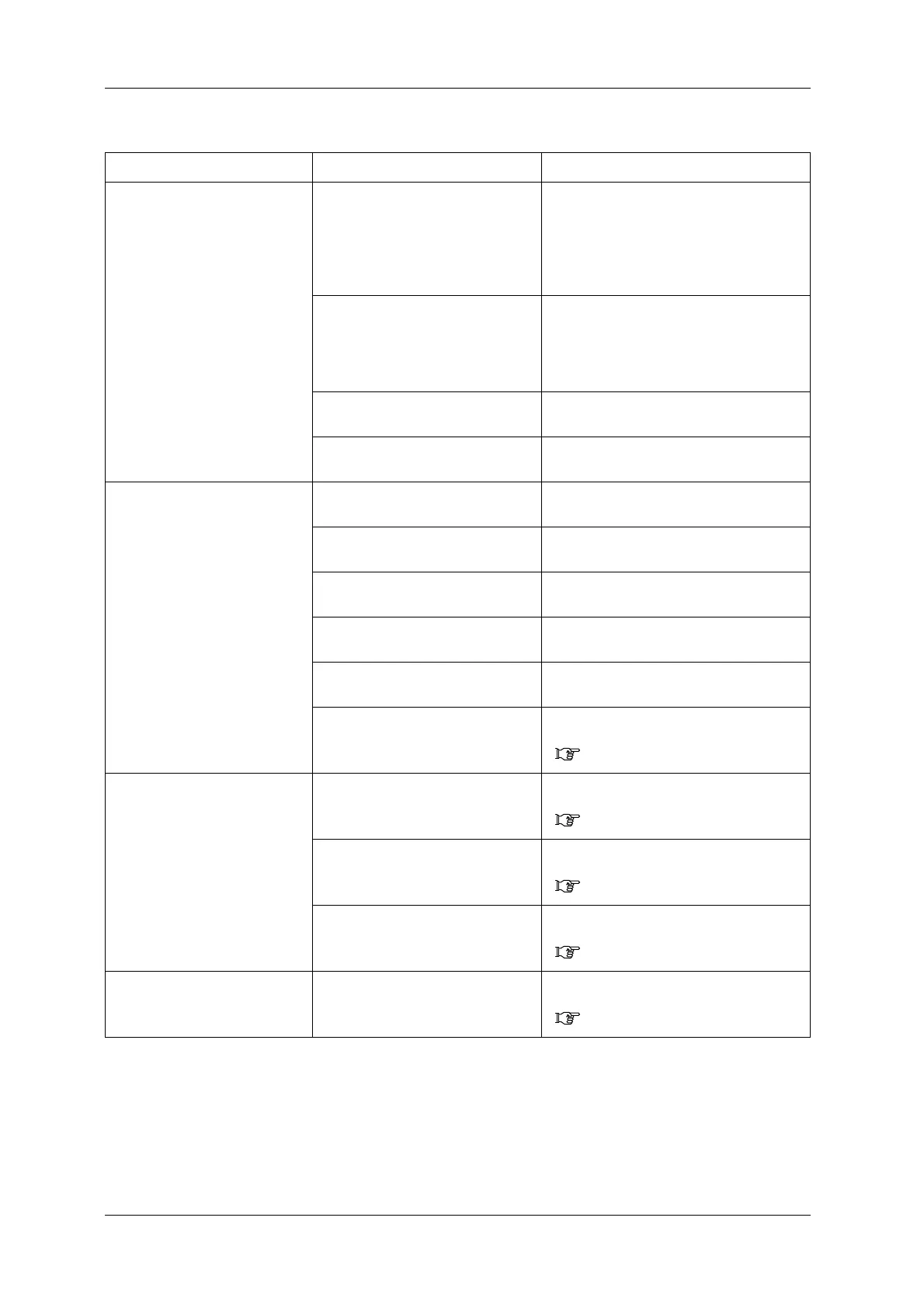

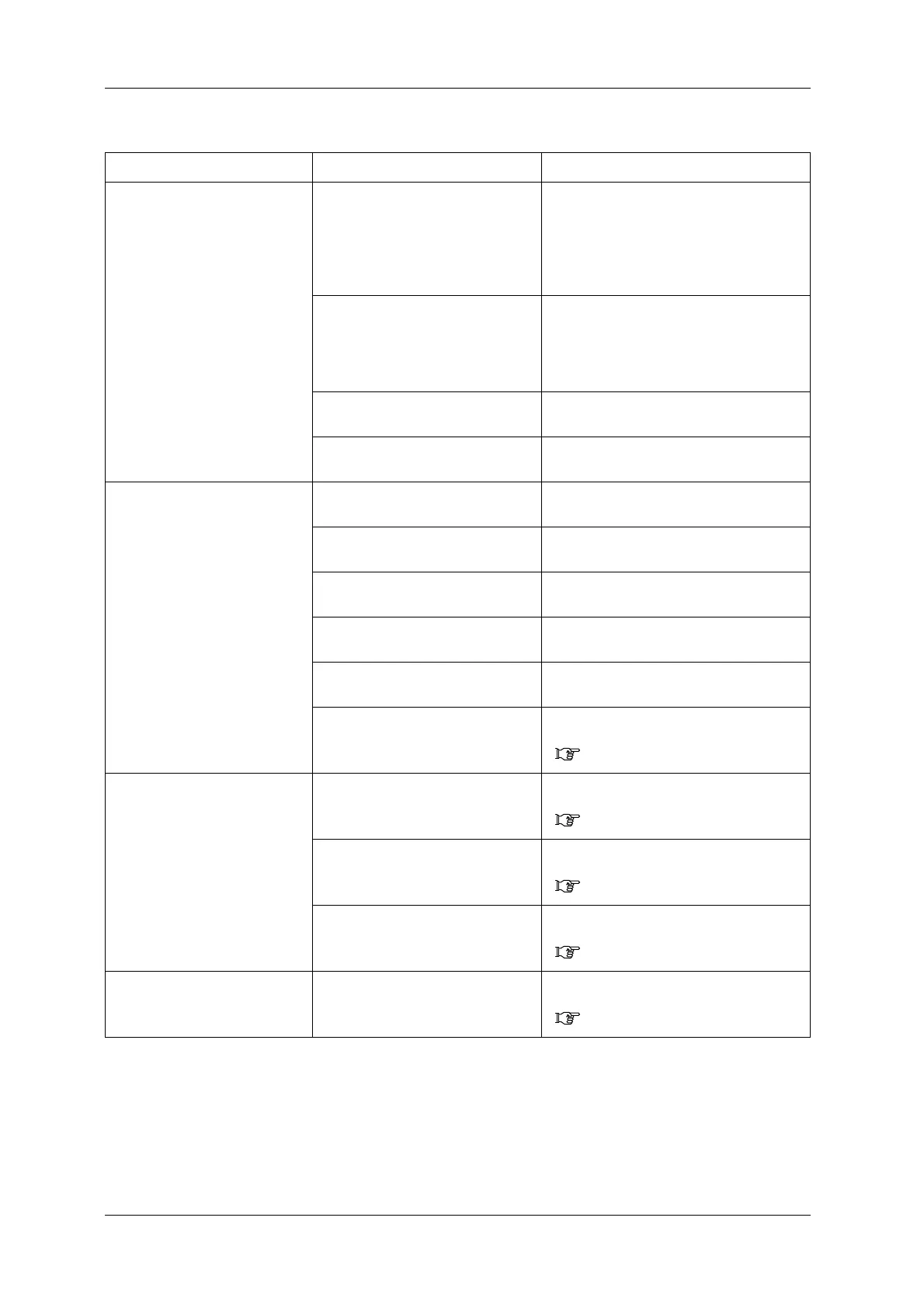

11 CAUSES AND ACTIONS FOR ERRORS AND FAILURES CCW-R-2**B INSTRUCTION MANUAL

11-18

Underweight occurs frequently. The amount of product supplied to a

hopper is insufficient.

• If 6-9 heads are selected for combination, the

amount of supplied product is insufficient. In

this case, increase the feeder amplitude or

time.

• Increase the set value of the dispersion

weight.

The amount of product supplied to the

dispersion unit is insufficient.

• Increase the amount of products supplied

from the infeed conveyor and raise the

position of the infeed control phototube in

order to prevent the shortage of the product

supply.

Affected by vibration. • Reinforce the scaffold.

• Increase the compensation value.

The speed is too high. • The set speed is too high for the product type

and volume. Decrease the speed.

The weight of the product is

significantly different from the

displayed weight.

The products are spilling from the

hopper.

• Clean the hopper.

The weigh hoppers make contact with

an object.

• Adjust the open/close timing of the hopper

(PH, WH).

A product is stuck to the chute or the

hopper.

• Eliminate the object.

• Clean the chute and the hopper.

Improper interlock timing with the

packer.

• Adjust the timing.

The products pass through the hopper. • Check the hopper timing adjustment set at the

remote control unit.

The setting of the head specification

switch on the DUC board is incorrect.

• Contact the distributor or Ishida customer

support.

Table 11-12

The feeder does not operate. The fuse is blown. • Contact the distributor or Ishida customer

support.

Table 11-12

Board malfunction. • Contact the distributor or Ishida customer

support.

Table 11-12

KM01 (electromagnetic contactor) is

not operating.

• Contact the distributor or Ishida customer

support.

Table 11-12

The line of a part or the entire

display lights up or goes out.

LCD unit malfunction. • Contact the distributor or Ishida customer

support.

Table 11-12

Table 11-10 Failure and Malfunction List (Continued)

Status Cause Action

Loading...

Loading...