11 CAUSES AND ACTIONS FOR ERRORS AND FAILURES CCW-R-2**B INSTRUCTION MANUAL

11-10

11.2.3 Pattern 3

If an error occurs during operation, draining, or zero adjustment, warning alarm sounds and the error

name is displayed.

When a pattern 3 error occurs, refer to “Table 11-4 Error Display List (Pattern 3)” to perform the

correcting action. When the action is completed, the error name disappears.

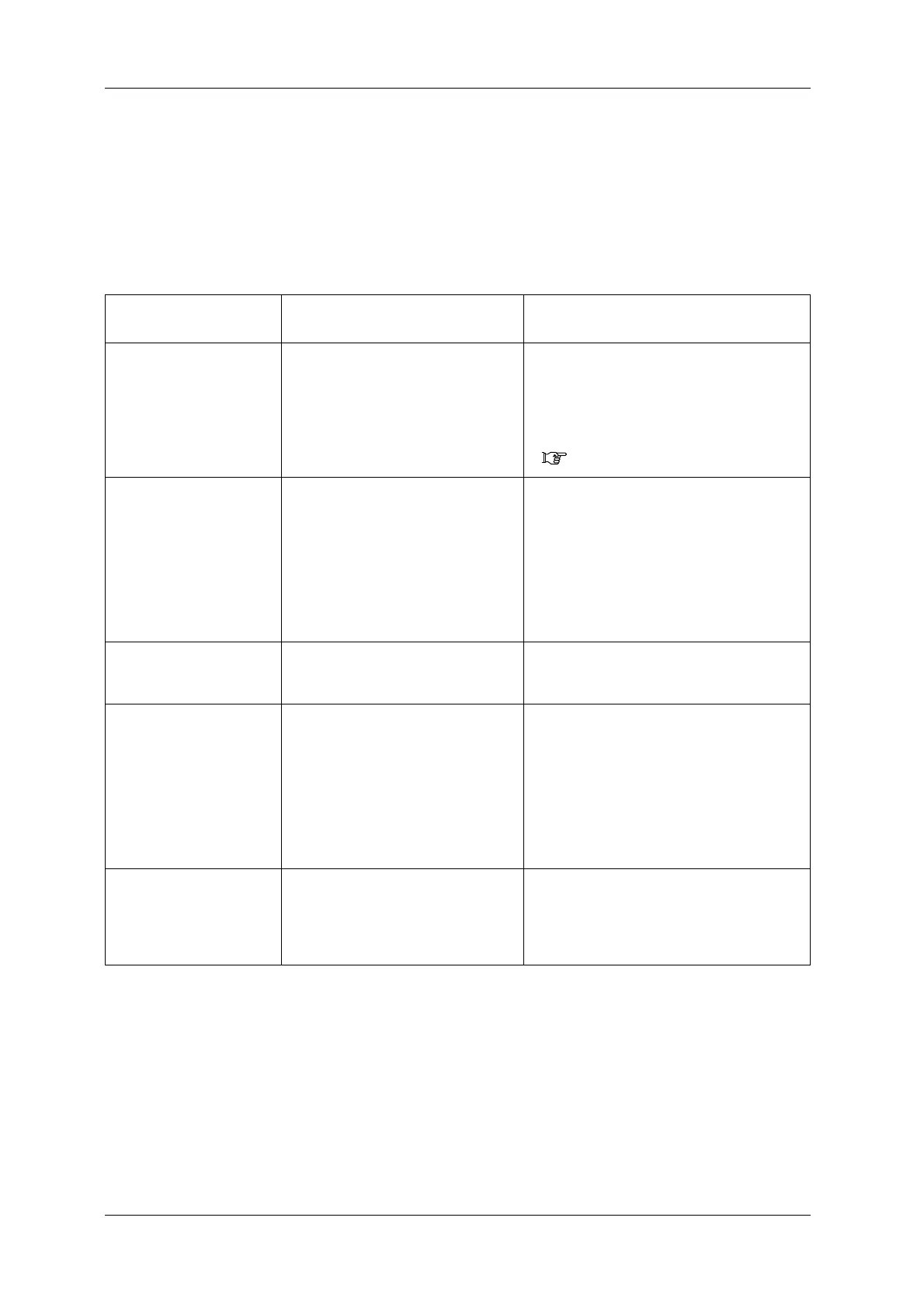

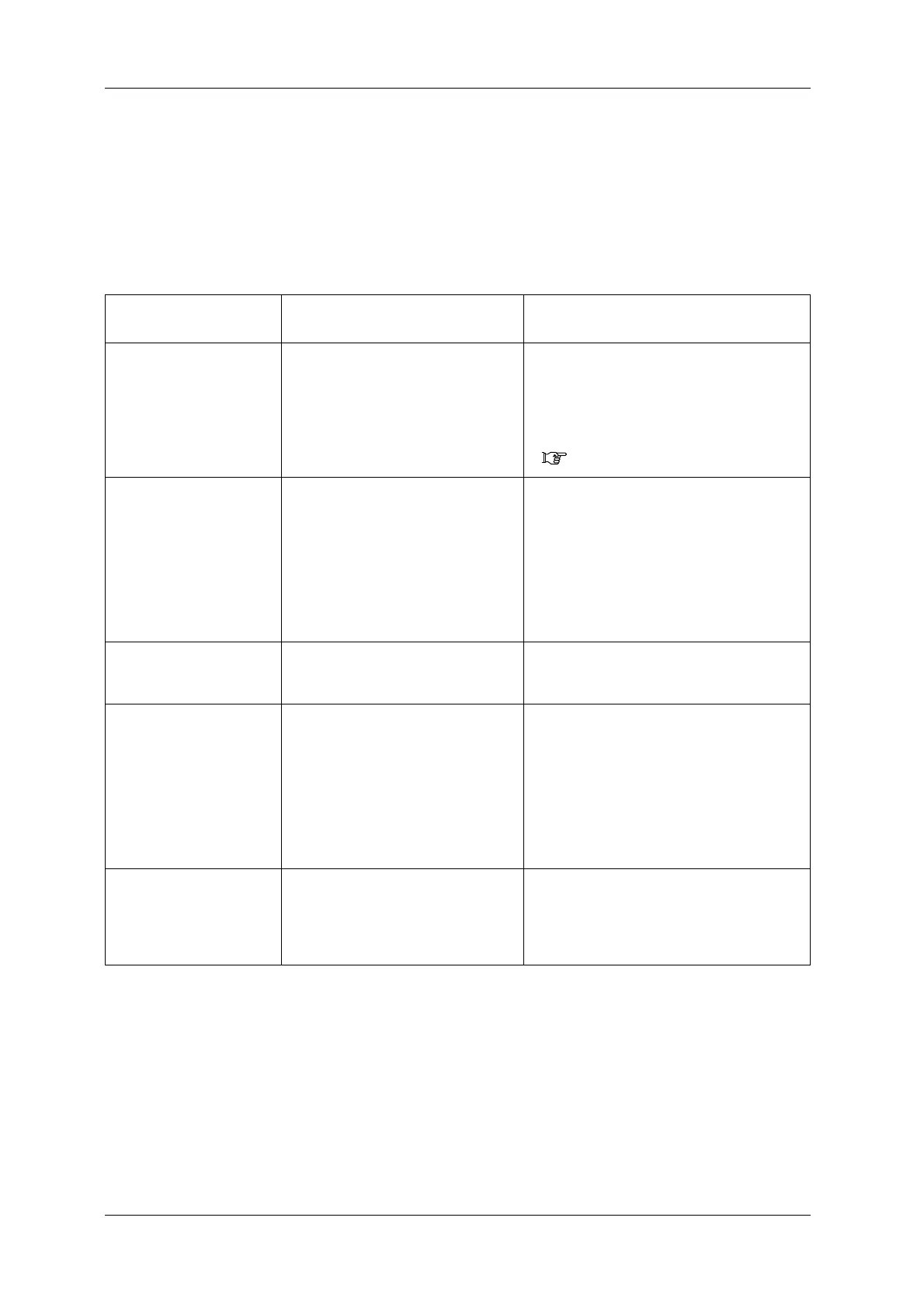

Table 11-4 Error Display List (Pattern 3)

Error Name/

Error Description

Cause Action

[WARNING: NO

TRANSMISSION]

1. Poor connection in the communication

line between the remote control unit

and the main unit.

(Unable to transmit data from the

remote control unit to the main unit.)

1. Check that the communication line between the

remote control unit and the main unit is

properly connected.

2. There is a possibility that the ADC, FDC or

WCU board is damaged. Contact the distributor

or Ishida customer support.

Table 11-11

[WARNING: NO

RESPONSE]

1. Poor connection in the communication

line between the remote control unit

and the main unit.

(The remote control unit was unable to

receive the communication data

transmitted from the main unit every

second for more than 5 seconds.)

2. The power is not being supplied to the

WCU.

1. Check that the communication line between the

remote control unit and the main unit is

properly connected.

2. There is a possibility that the WCU board is

damaged. Contact the distributor or Ishida

customer support.

[LOW PRODUCT] 1. The product counts on the dispersion

table are small.

1. Supply products to the dispersion table.

2. If continued operation with low products is

desired, set the [Infeed Control] key to OFF.

[WARNING: OVERSCALE] 1. This error occurs when weighted

product over “target weight + upper

weight limit” or “set target count +

upper count limit” is supplied to one

head.

A warning message will be displayed

only when the overscale head count is

less than the set head count or the head

count is set to “0”.

1. Decrease the feeder amplitude or time by

making feeder adjustment.

2. Decrease the amount of products supplied to the

dispersion table.

(Decrease the dispersion weight.)

[WARNING: DETACHED

HEAD]

1. The weigh hopper is not installed.

2. Zero adjustment was performed with a

product stuck to the weigh hopper, and

the weighted product came out of the

weigh hopper.

1. Make sure that the weigh hopper is properly

installed.

2. Check that there is no product stuck to the

weigh hopper, then perform zero adjustment.

Loading...

Loading...