CCW-R-2**B INSTRUCTION MANUAL 12 INSTALLATION

12-15

12.4.15 Connecting to Interlocking Device

Connect the interlock signal wires of the relay unit to the interlocking device such as packer and feeder.

• When other devices need to be connected before and after this weighing

machine, shut off the power for all of the devices. Failure to do so may cause

an electrical shock.

• In order to prevent malfunction of the weighing machine, route the interlock

signal wire away from the power cables.

When using relays and contactors as a load, prevent induction noise by using

a surge killer or other methods.

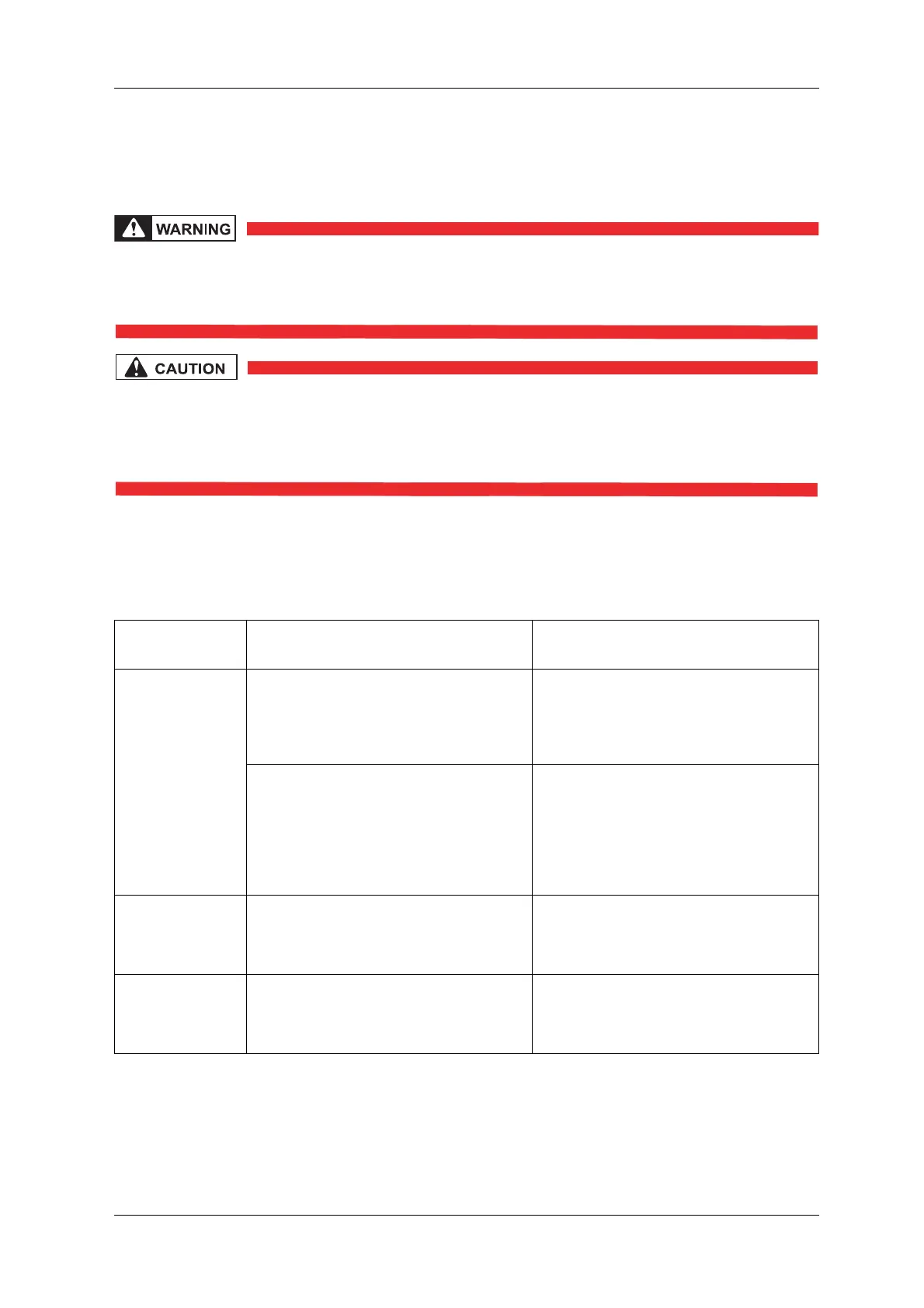

(1) Specifications of the interlocking device signal

For the interlocking device signals, follow the specifications below.

Table 12-4 Specifications of the Interlocking Device Signal

Interlock Target Signal Input/Output Characteristics of the

weighing machine

1. Packer • Interlock signal.

The interlock signal from the packer to the

weigher should output a no-voltage contact

signal.

• Input characteristics.

Circuit: opto-isolator.

Voltage: 24VDC.

Current: approx. 15 mA.

Signal width: min. 50 msec.

• Discharge completion signal.

The discharge completion signal from the

weigher to the packer outputs a no-voltage

contact signal.

• Output characteristics.

Circuit: relay contact.

Rating: connect 250V, the load of AC5A or

lower.

Signal width: set arbitrary with the remote

control.

(Default value is 100 msec)

2. Infeeder • Infeed control signal.

The feed signal from the weigher outputs a no-

voltage contact signal.

• Output characteristics.

Circuit: relay contact.

Rating: connect 250V, the load of AC5A or

lower.

3. Other • Error signal.

The error signal from the weigher outputs a no-

voltage contact signal.

• Output characteristics.

Circuit: relay contact.

Rating: connect 250V, the load of AC5A or

lower.

Loading...

Loading...