Epson Stylus Pro 4900/Epson Stylus Pro 4910 Revision A

ADJUSTMENT Overview 289

Confidential

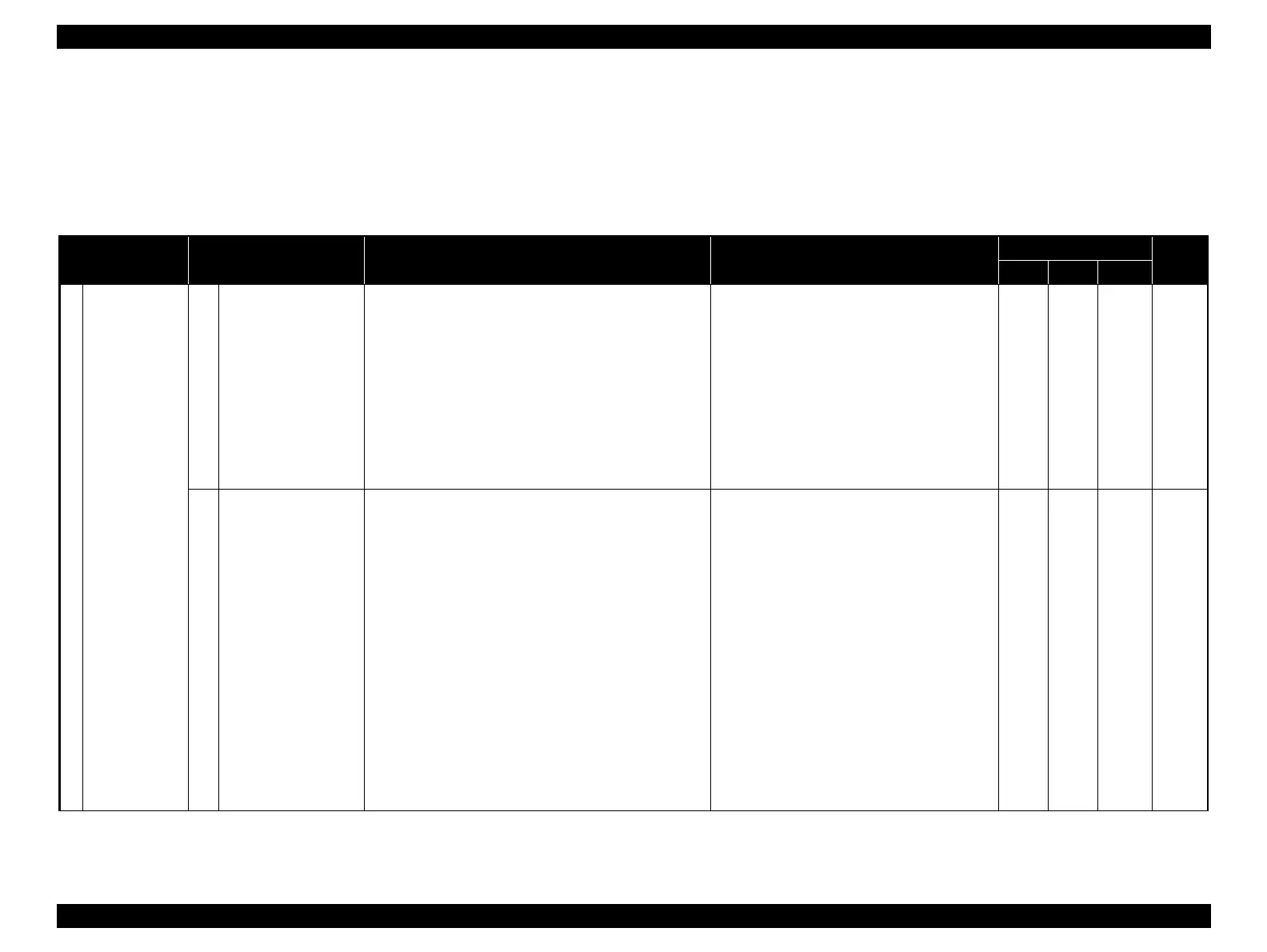

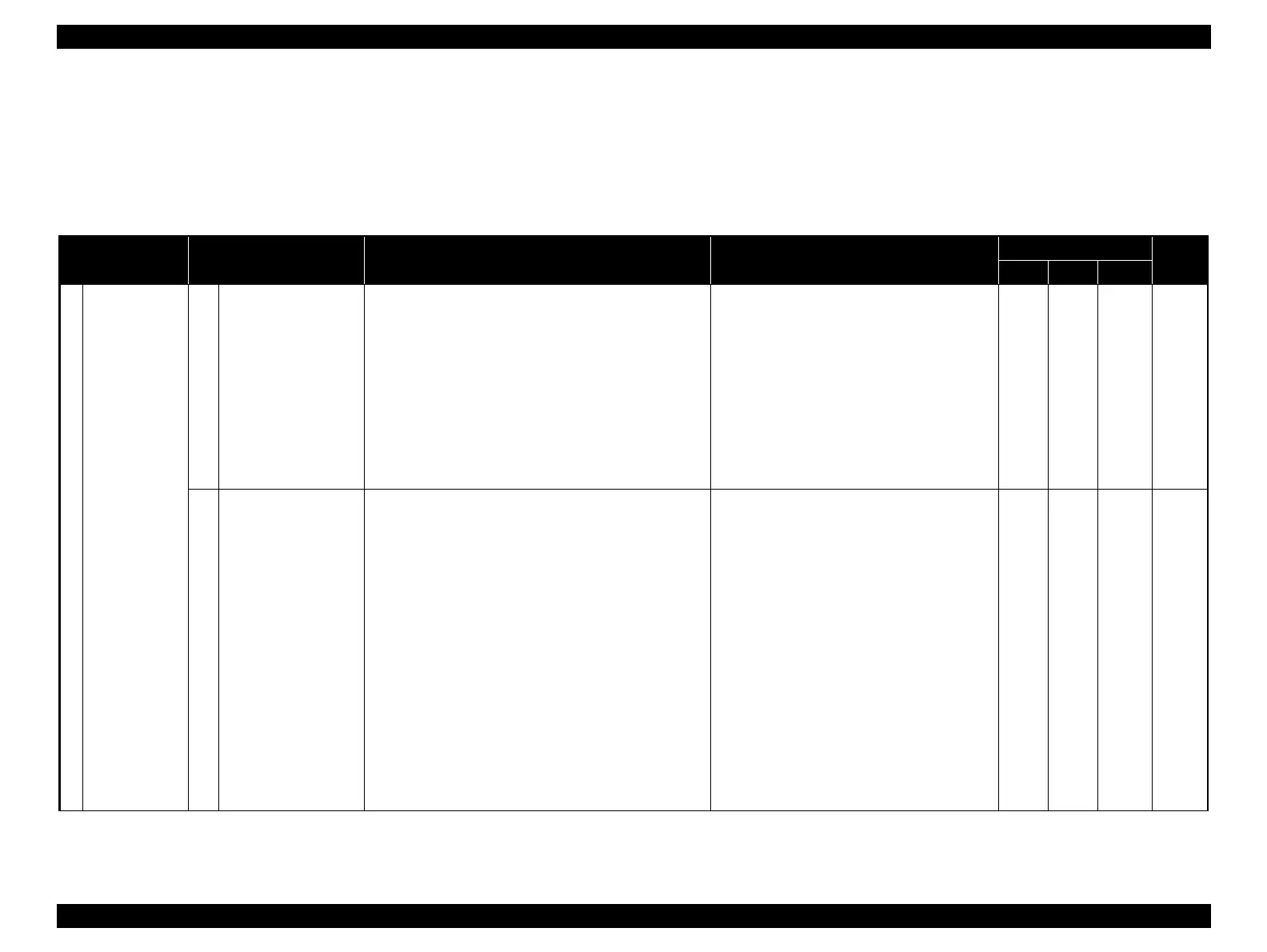

4.1.3 Description of Adjustments

The following table describes the general outline of the adjustments.

Note : The meanings of abbreviations in the “Tool” column are as follows.

SP = Service Program

SM = Serviceman Mode

MECH = Mechanical Adjustment can be performed. (In some cases, a dedicated tool for the adjustment or a commercially available tool such as a tension gauge is necessary.)

Class Adjustment Items General Overview Symptom

Tool

Page

SP SM MECH

1 CR Related

1

FFC Position Check

Check visually that the Ink Tube and the Head FFC are

routed properly so that they do not contact each other and

the clamps are secured at the correct positions between the

CR Unit and the joint section of the tube.

By the carriage operation, the Head FFC, Ink

Tube, and clamps may contact each other and

the parts are damaged.

Head FFC is routed too slackly:

The Head FFC may contact to the Ink Tube

and the Ink Tube is damaged.

Head FFC is routed too tightly:

The Head FFC may be caught in the clamp

and the top or the bottom edge of the FFC is

damaged. (In this case, a Service Call of head

system such as Thermistor Error occurs.)

--- --- √ p.316

2

CR Belt Adjustment

Give a specified tension to the CR timing belt. Measure the

tension using the Sonic Tension Meter to check if it is

within the standard value. If it is not within the standard

value, adjust the tension.

When the tension is out of the standard value,

the following symptoms may occur.

Belt tension is high:

The life of the belt will be shortened.

The load gets higher, and the CR

operation gets Wait control by the

heating control.

If the tension is too high, the shaft of the

motor leans and the brush in the motor is

worn. This will cause the CR overload

error (SC113A).

Belt tension is low:

Slipping of the teeth of the belt occurs

and the Carriage swings. The correction

by the active damper does not work and

the bands (vertical bands) occur near the

side edges of paper.

√ --- √ p.319

Loading...

Loading...