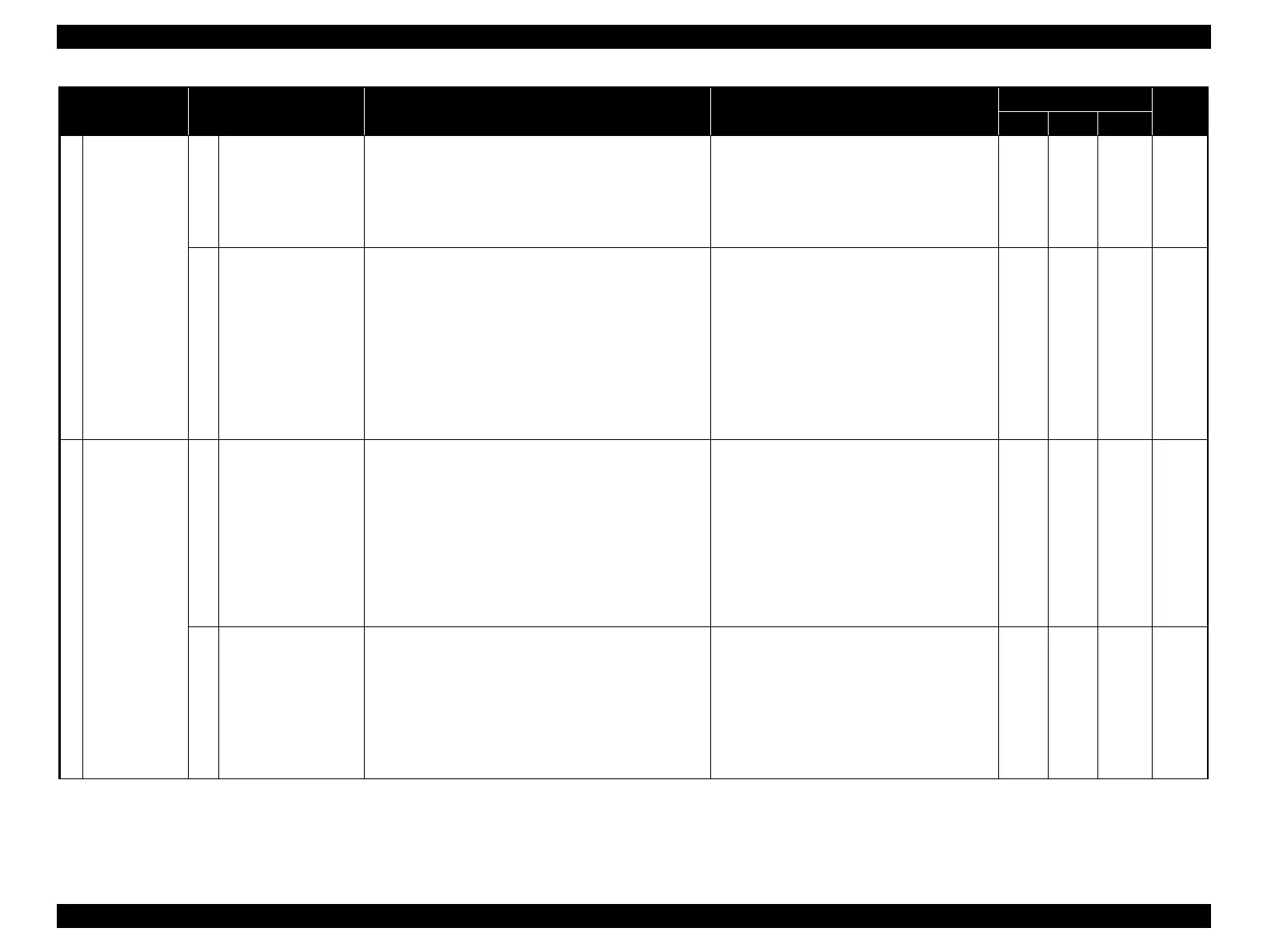

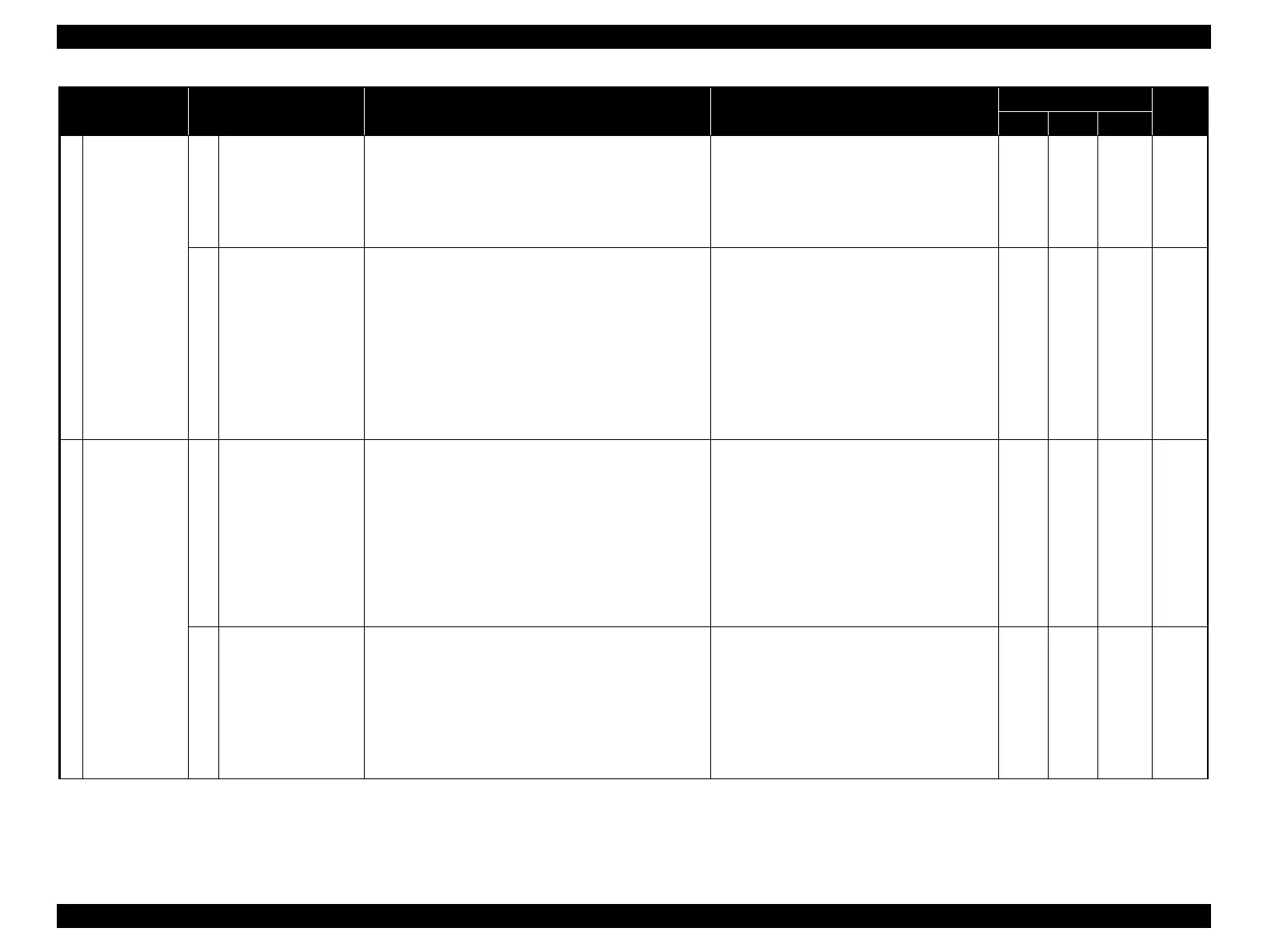

Epson Stylus Pro 4900/Epson Stylus Pro 4910 Revision A

ADJUSTMENT Overview 291

Confidential

1 CR Related

7

Active Damper

Adjustment

Execute the calibration of the active damper from the

Service Program.

* Active damper is a function to reduce the carriage

vibration which causes the vertical bands by outputting the

waveform which has opposite phase from the motor

vibration.

The motor vibration/carriage vibration may not

be reduced, and the vertical bands occur.

√ --- --- p.329

8

Ink Mark Sensor Check

& Adjustment

Select and execute the following menu from the Service

Program.

1. Check if the Ink Mark Sensor has any trouble/

connection failure.

2. Execute IMS Position Auto Correction (pattern

detecting position correction). Correct the detecting

position of the print pattern in the sub scan direction

and the main scan direction.

3. Execute the automatic nozzle check to check if the Ink

Mark Sensor detects the nozzle clogging properly.

If the IMS does not work properly, Auto Bi-D

Adjustment cannot be executed normally.

√ --- --- p.330

2 Head Related

1

Head ID Check & Input

Register the head rank ID to the printer using the Service

Program and check the currently registered value. Head

rank ID is the ID to drive the Printhead with the proper

voltage and correct the amount of ink droplets. The ID is

assigned to each head and listed on the label on the head.

If the new ID is not registered after replacing the

head, the head ID of the older head is used and

the proper drive voltage cannot be set. The

following symptoms may occur.

Since the amount of ink droplets is not

proper, the color and density abnormalities

are found on the result.

Since the amount of ink droplets turns to be

unstable, dot missing or misaligned dots

occur while printing or flushing.

√ --- --- p.332

2

Nozzle Check

Print the pattern on which the nozzle discharging condition

can be checked from the Service Program.

When the Nozzle Check is not executed and the

nozzle is clogging, the following symptoms may

occur.

The adjustment pattern is not printed properly

and it causes a trouble for the automatic and

visual check/adjustment.

In the automatic adjustment, it causes failure/

error.

--- √ --- p.334

Class Adjustment Items General Overview Symptom

Tool

Page

SP SM MECH

Loading...

Loading...