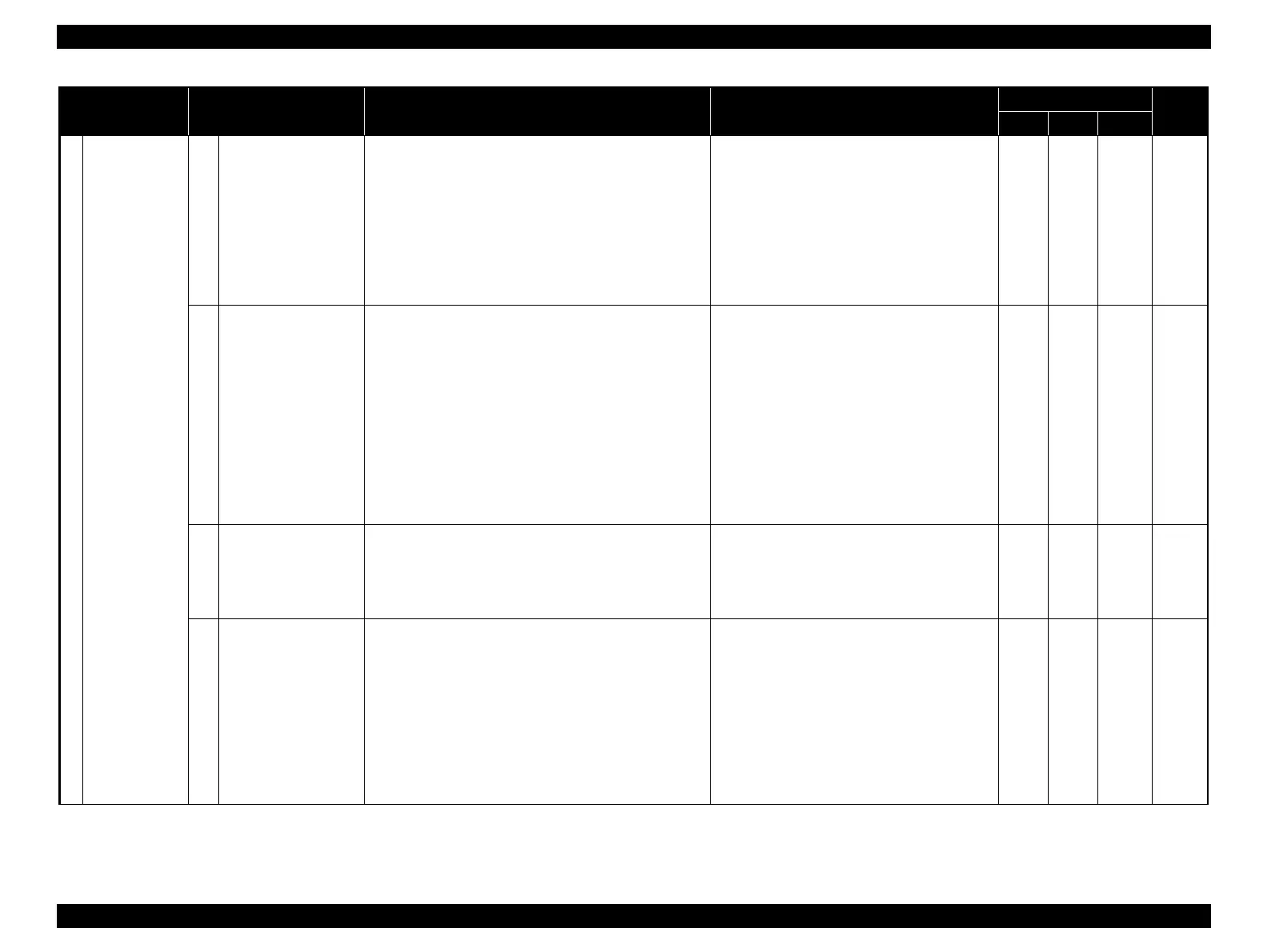

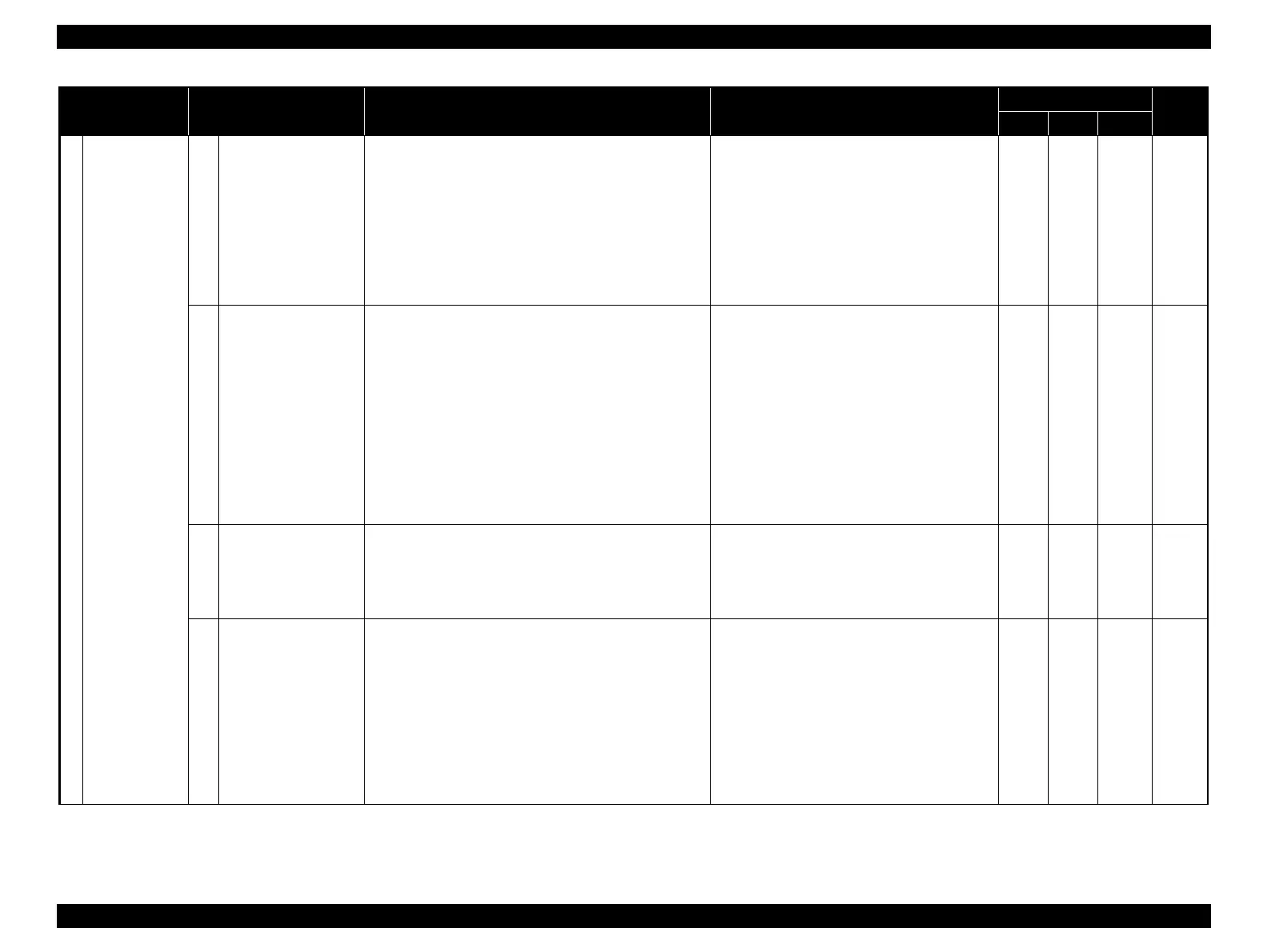

Epson Stylus Pro 4900/Epson Stylus Pro 4910 Revision A

ADJUSTMENT Overview 292

Confidential

2 Head Related

3

Cleaning

Specify the power and the color from the Service Program

and execute the head cleaning.

When the cleaning is not executed, the following

symptoms may occur.

Nozzle clogging is not solved and the

printing cannot be executed properly.

Ink does not come out and the printing cannot

be executed after replacing to a new

Printhead. (Executing Initial Charge may

solve this problem but it takes time and

consumes lots of ink.)

√ --- --- p.335

4

CR & PF Direction

Head Slant Adjustment

Print the pattern on which the tilt of the Printhead in CR

and PF directions can be checked from the Service

Program, and check the misalignment level visually.

When the misalignment symptom is observed, turn the

adjustment dial (in CR direction) and the adjustment lever

(in PF direction) of the carriage to correct the tilt.

If CR Direction Head Slant Adjustment is not

executed, the printing position is misaligned

on the whole rows of the Printhead, and it

may cause low printing quality such as

grainy image, banding, and unevenness.

If the PF Direction Head Slant Adjustment is

not executed, flow curve or difference of

spotted ink locations occurs since the

distances from paper differ between the front

side and the rear side of the Printhead. It may

cause low printing quality such as grainy

image, banding, and unevenness.

--- --- √ p.336

5

Auto Bi-D Adjustment

Reduces the difference of spotted ink locations on Bi-D

printing (bi-directional printing).

If Auto Bi-D Adjustment is not executed, the

difference of spotted ink locations may occur,

and it causes low printing quality such as

printing misalignment, grainy image, and

banding.

√ --- --- p.341

6

Colorimetric

Calibration Adjustment

Adjust the amount of ink droplets responding to the

characteristics of the Printhead and the electrical

characteristics (dependent to the Main Board and the

Power Supply Board) which differ depending on the

printer. Use the dedicated software and the Color

Measurement Device for this adjustment.

Measure the print pattern with the Color Measurement

Device, create the correction value from the result, and

then write the value to the NVRAM. The printer reads the

correction value to correct the amount of ink droplets.

If Colorimetric Calibration Adjustment is not

executed, the ink droplets amount changes when

replacing the Printhead, Main Board, or Power

Supply Board, and it causes a variability of color

on the printed result depending on the printer.

√ --- --- p.342

Class Adjustment Items General Overview Symptom

Tool

Page

SP SM MECH

Loading...

Loading...