SHOP MANUAL

Engine

Ch 1 page 96

Removing and dismantling connecting rods and

pistons

1. Remove the cylinder head and oil sump.

2. Remove the piston cooling nozzle in the cylinder block.

The piston cooling nozzle must not be damaged. The oil jet

must hit the piston precisely. If it does not, the piston will

become too warm resulting in engine breakdown. Damaged

nozzles must not be straightened. They must be renewed.

3. Remove the bearing cap and bearing shells.

Protect the oil way in the crankcase using, e.g. adhesive tape,

applied with the sticky side out.

4. Mark the piston and connecting rod before removing them.

They must be refitted in the same place and in the same way.

5. Lift out the piston and connecting rod.

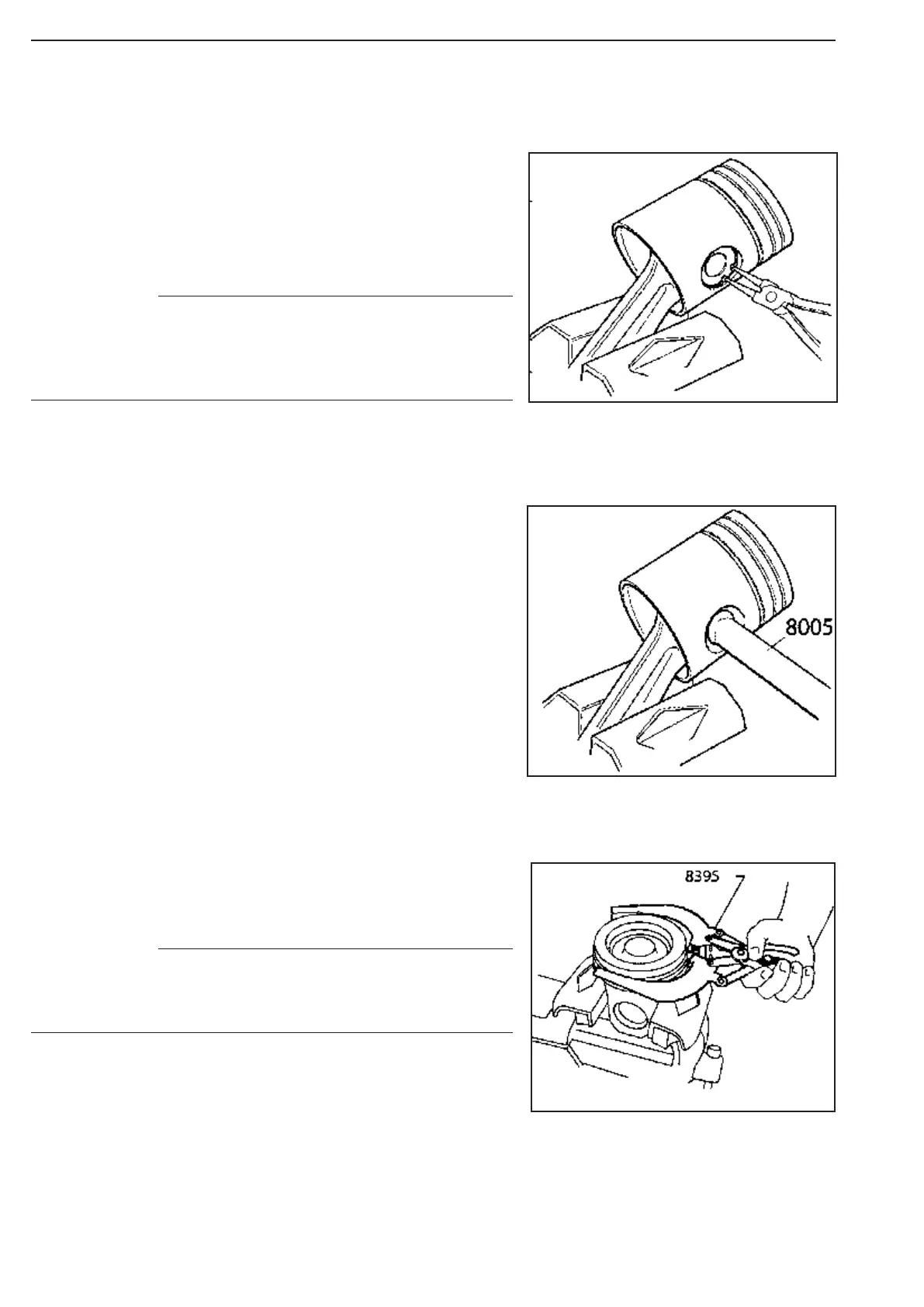

6. Place the connecting rod in a vice with soft jaws. Remove the

retaining rings for the gudgeon pin.

7. Push out the gudgeon pin using drift 8005.

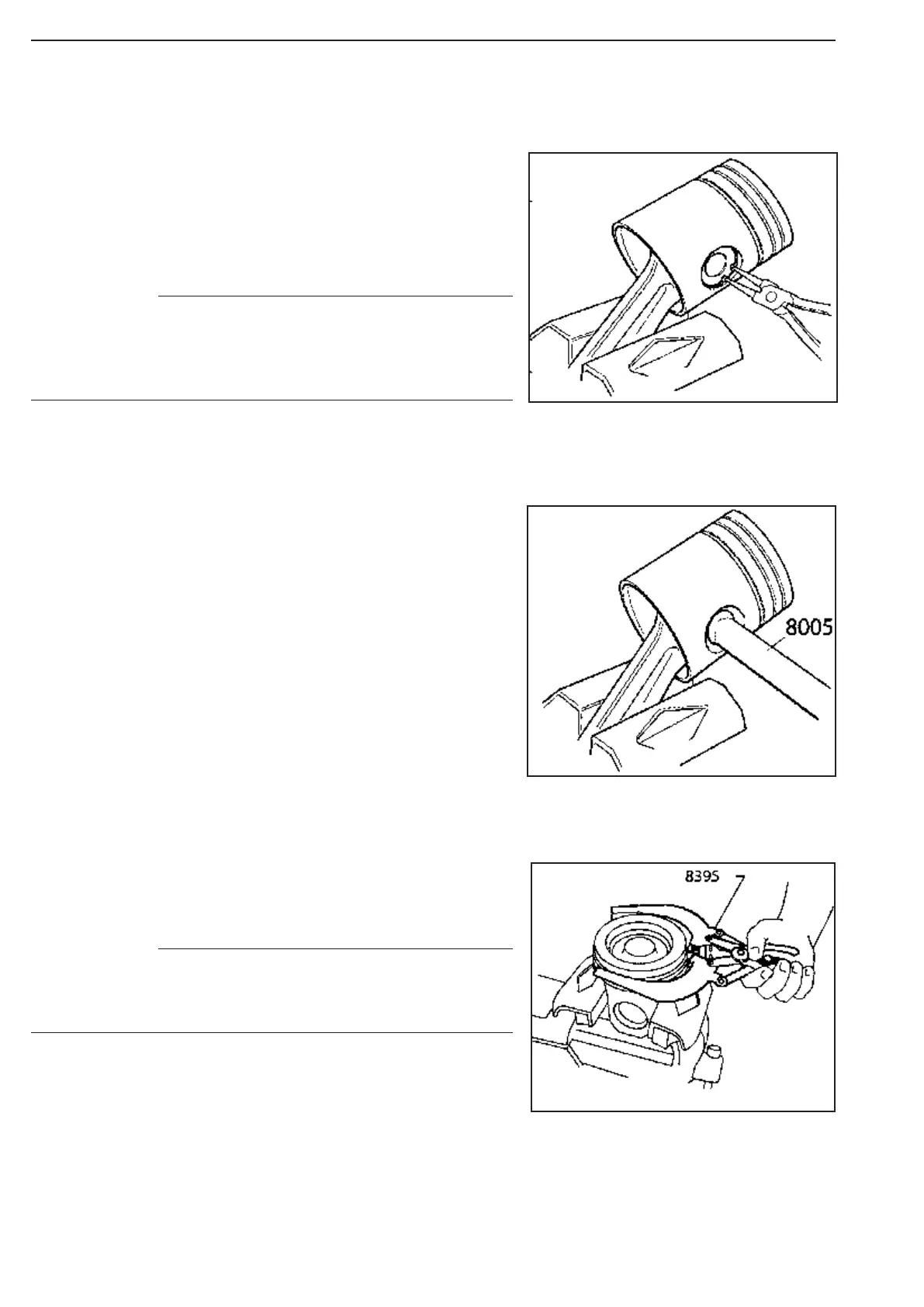

8. Remove the piston rings using tool 8395, taking care to avoid

scratching the surface of the piston skirt with the piston rings.

9. When cleaning graphited pistons in a machine, the graphiting

may disappear.

This does not matter after they have been in use for a while.

However, new pistons should be washed carefully using white

spirit or the like.

Always inspect the connecting rod in cylinders which have

seized, been lled with water or where the valve has broken.

Bent connecting rods must not be straightened.

NOTE

NOTE

Figure 180

Figure 181

Figure 182

Loading...

Loading...