Ch 6 page 69

ELECTRICAL SYSTEM

SHOP MANUAL

Engine speed sensors

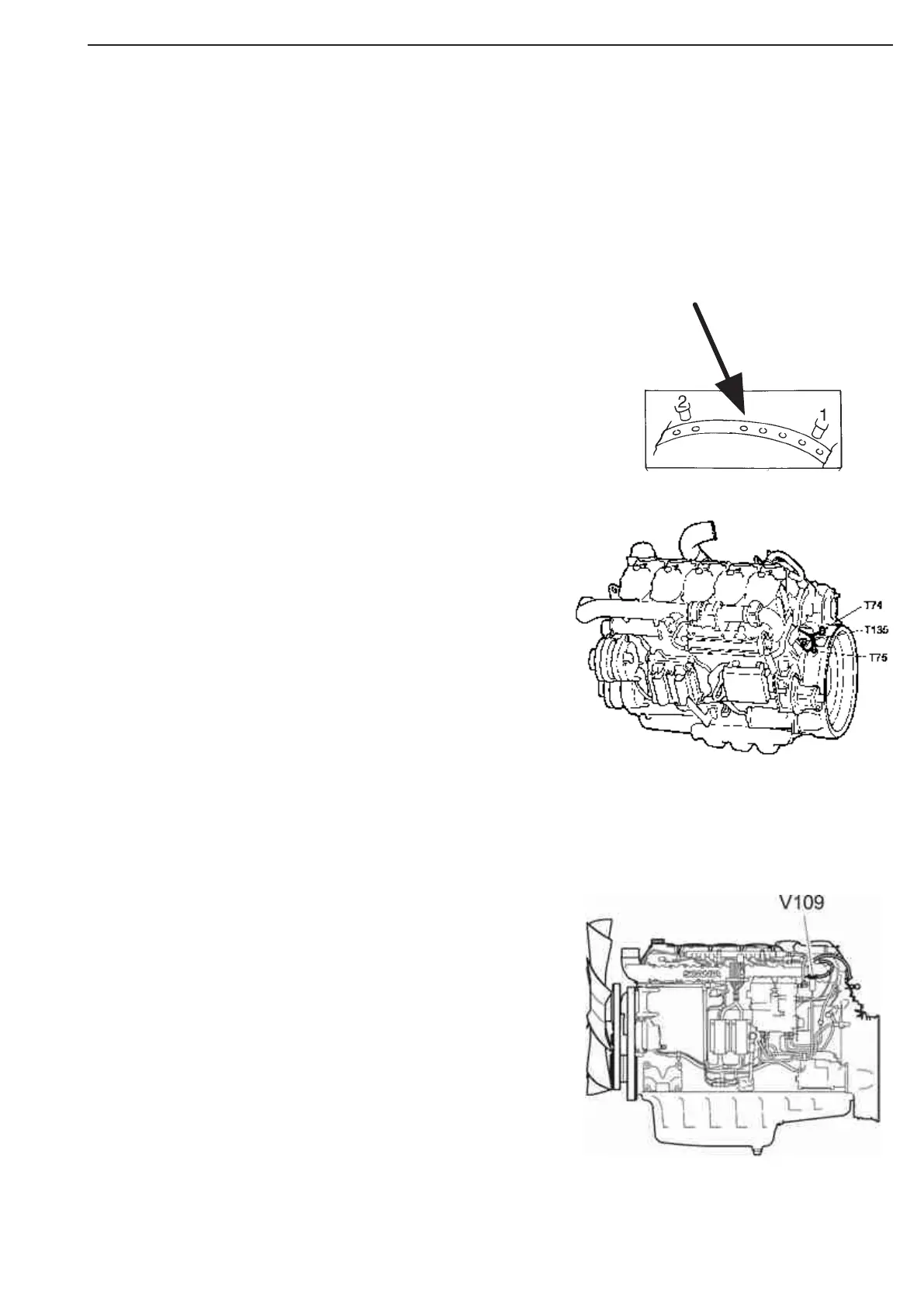

1 Engine speed sensor 1, T74

2 Engine speed sensor 2, T75

The detail shows some of the holes in

the flywheel that are detected by the

engine speed sensors.

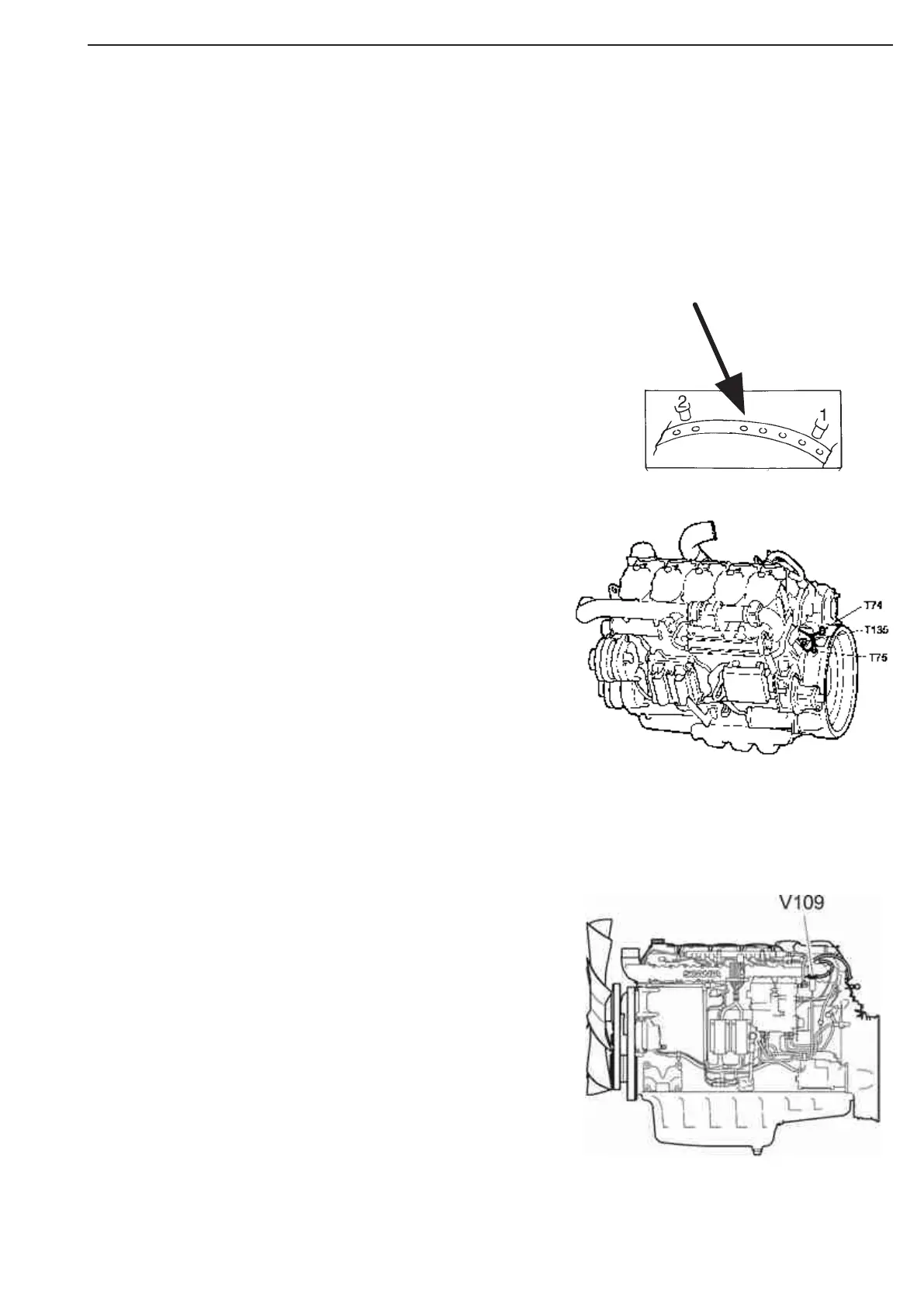

There are two engine speed sensors in the EMS system, en-

gine speed sensor 1 and engine speed sensor 2. The sensors

are inductive. This means that they only produce signals when

the engine is running.

The signal strength varies significantly, depending on the air

gap between the sensors and the flywheel as well as on the

engine speed.

The EMS system performs an assessment of the signal

strength at different engine speeds.

If the signal strength becomes too low, a fault code is gener-

ated.

Both engine speed sensor 1 and engine speed sensor 2 read

the position of the flywheel.

This means that the system cannot determine which of two

possible revolutions the engine is at, i.e.

whether, for example, cylinder 1 or cylinder 6 is at the ignition

position.

Every time the engine is stopped and the voltage cut off, the

engine position is stored.

Next time the voltage is switched on, the stored position of the

engine is used to determine which

revolution the engine is at.

When the engine has started, a system check is performed to

verify that the stored position is correct.

Resistance: 485-595 W

Inductance: 187-253 mH

Measure between: 541- 1 and 2

Distance between sensor and

flywheel/gear ring: 0,5- 1,5mm

Engine speed and camsghaft sensors

The solenoid valve for the wastegate

valve receives signals from the

engine control unit and regulates the

turbocharger charge pressure via the

wastegate valve.

Wastergate solenoid valve

Figure 50

Figure 49

Figure 51

Loading...

Loading...