SHOP MANUAL

DRIVE LINE

Ch 3 page 102 Ch 3 page 103

DRIVE LINE

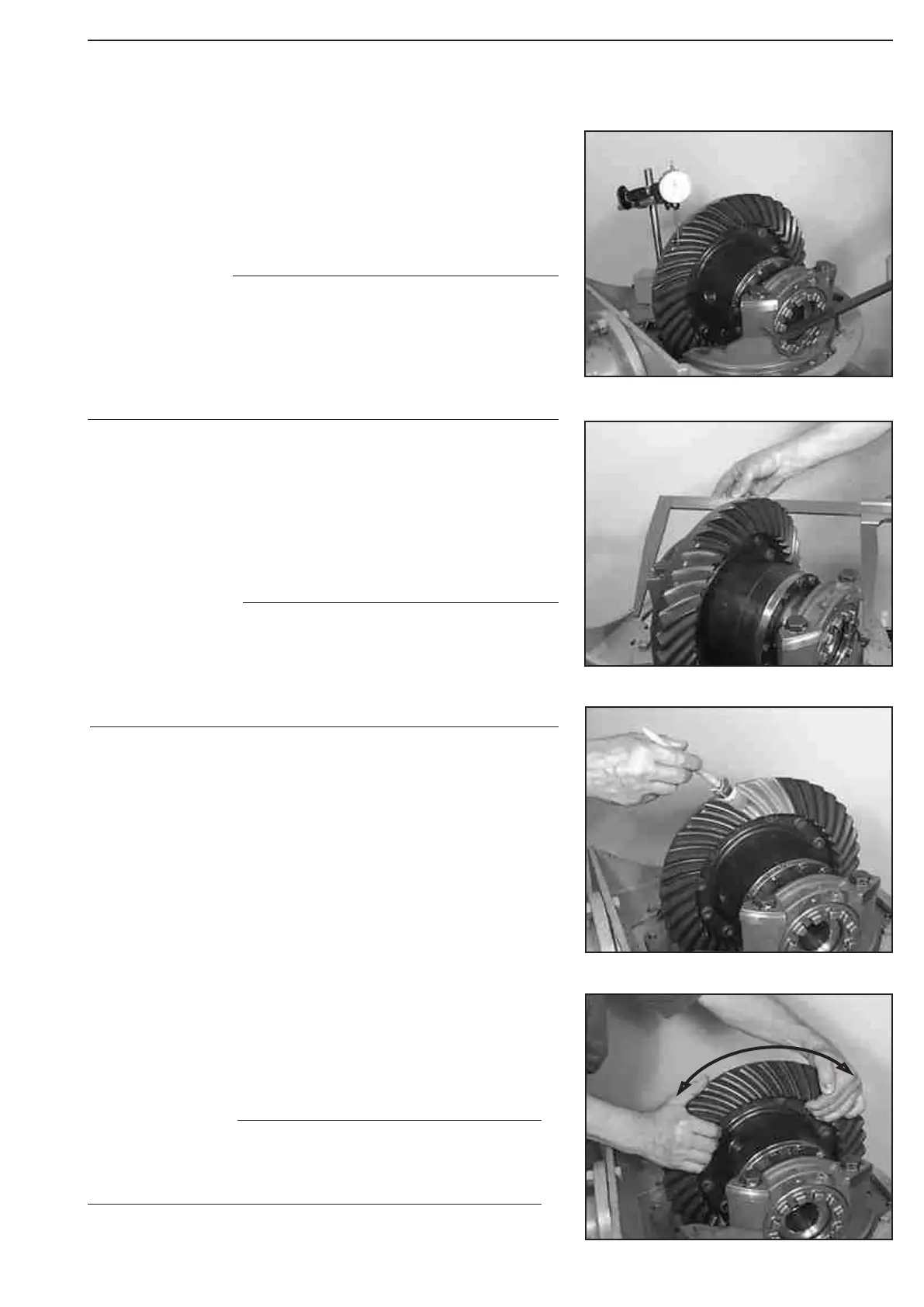

Adjust Backlash - Bevel gear set = 0,27 ... 0,33 mm

Bearing torque - Differential bearing T = 3 ... 4 Nm

and

Yoke width = 472 - 0,2 mm (Figure 290 ... 291):

Determine the backlash by the alternating adjustment of the two

adjusting nuts (Figure 290).

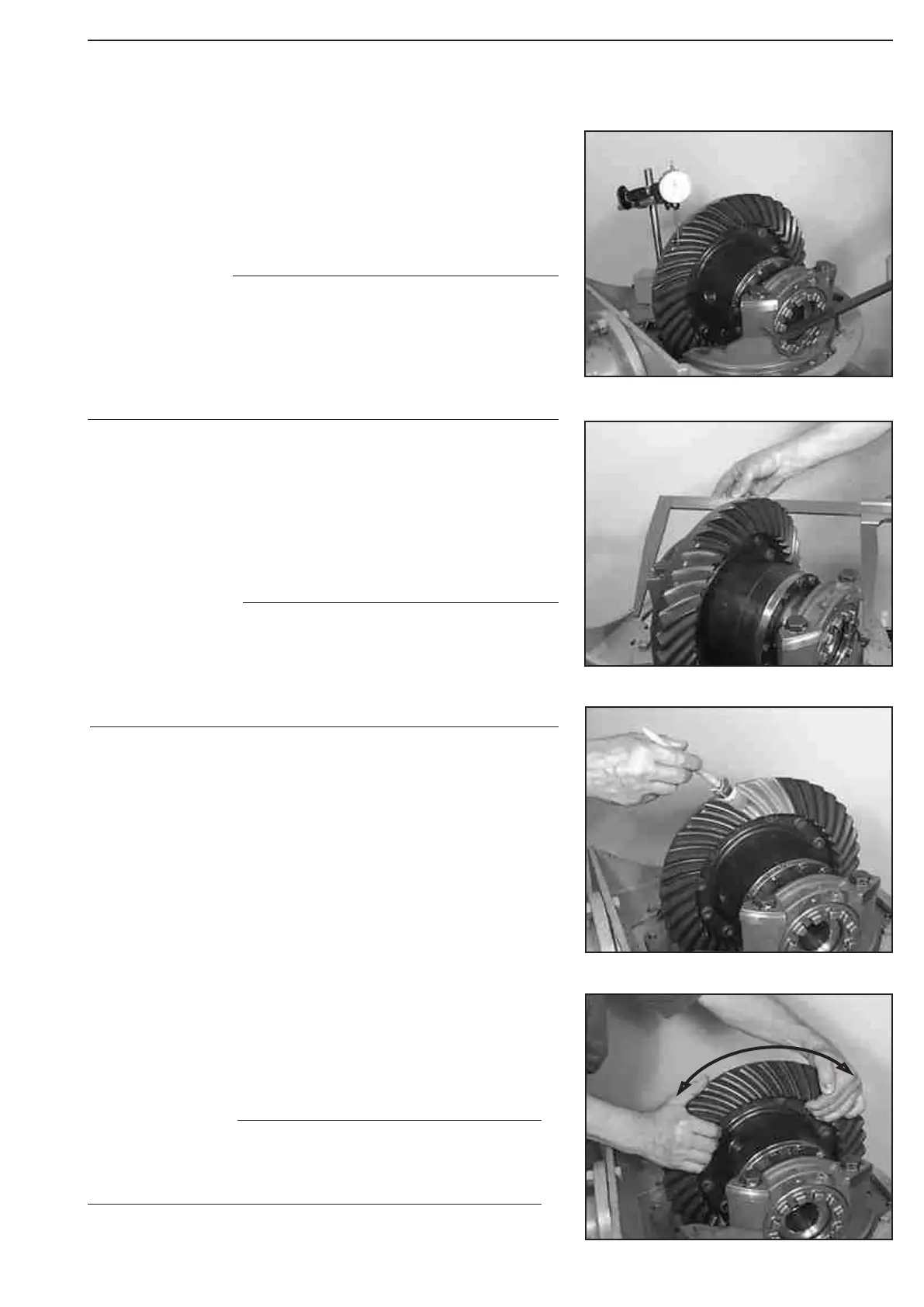

Roll crown wheel several times in both directions over the drive

pinion.

Compare the obtained contact pattern with the Examples of Con-

tact patterns, (See next pages, examples of

gear-tooth-contact patterns

Check Contact pattern (Figure 292 ... 293) !

Cover some driven and driving flanks of the crown wheel with

marking ink.

(S) Plastic mallet 504196

(S) Crow bar 504209

(S) Magnetic stand 504171

(S) Dial indicator 504172

(S) Precision micrometer 509260

Now, adjust both adjusting nuts further for about 1 notch.

Adjust Backlash

Adjust the adjusting nuts without greater force - differential

bearing must not yet be preloaded, however must be abso-

lutely playfree! To ensure this, rotate the differential during

the adjustment procedure several times as well as relax the

bearing by tap ping onto both bearing brackets (use plastic

mallet)!

We know from experience that by adjustment of the two

adjusting nuts for about 1 notch each, the required bear-

ing torque of the differential bearing as well as the bearing

bracket dimension is obtained ! Check bracket dimension

and backlash once more and correct if necessary.

NOTE

In case of a contact pattern deviation, a measuring error

has been made at the determination of the shim (Figure

258), which must be absolutely corrected!

NOTE

NOTE

Figure 293

Figure 292

Figure 291

Figure 290

Loading...

Loading...