SHOP MANUAL

DRIVE LINE

Ch 3 page 44 Ch 3 page 45

DRIVE LINE

Prior to start the test, ventilate the brake hydraulics

completely!

1. Open the bleeder.

2. Actuate the HP-pump slowly until oil gets out of the bleeder.

3. Close the bleeder again.

4. Pressurize the HP-Pump slowly with p > 10 bar and

keep the pressure for some seconds.

5. Loosen shut-off valve on the HP-pump.

6. Open the bleeder again.

7. Actuate the HP-pump slowly until oil gets out of the bleeder.

ATTENTION:

Repeat the procedure (Point 3 ... 7) until (at Point 7)

from starting of the actuation no more air comes out of

the bleeder.

Then pressurize the brake temporarily

(5x) with p = 100 bar max.!

High-pressure test:

Increase test pressure up to p = 100 –10 bar and close

connection to the HP-pump by means the of shut-off valve.

During a 5 min. testing time a pressure drop of max. 2 %

(2 bar) is allowed!

If maximum pressure of 100 bar is exceeded, here will be an

excessive piston adjustment and a repeated disassembly

of brake or of the adjusting is required to reset the gripping

rings to the adjusting dimension.

Low-pressure test:

Reduce test pressure to p = 5 bar and close the shut-off valve

again.

During a 5 min. testing time a pressure drop is not allowed!

Test media

Motor oils SAE 10-W corresponding with,

MIL-L 2104 C, MIL-L 46152,

API-CC, CD, SC, SD, SE,

ATF-Oils Type A, Suffic A Dexron

of II D.

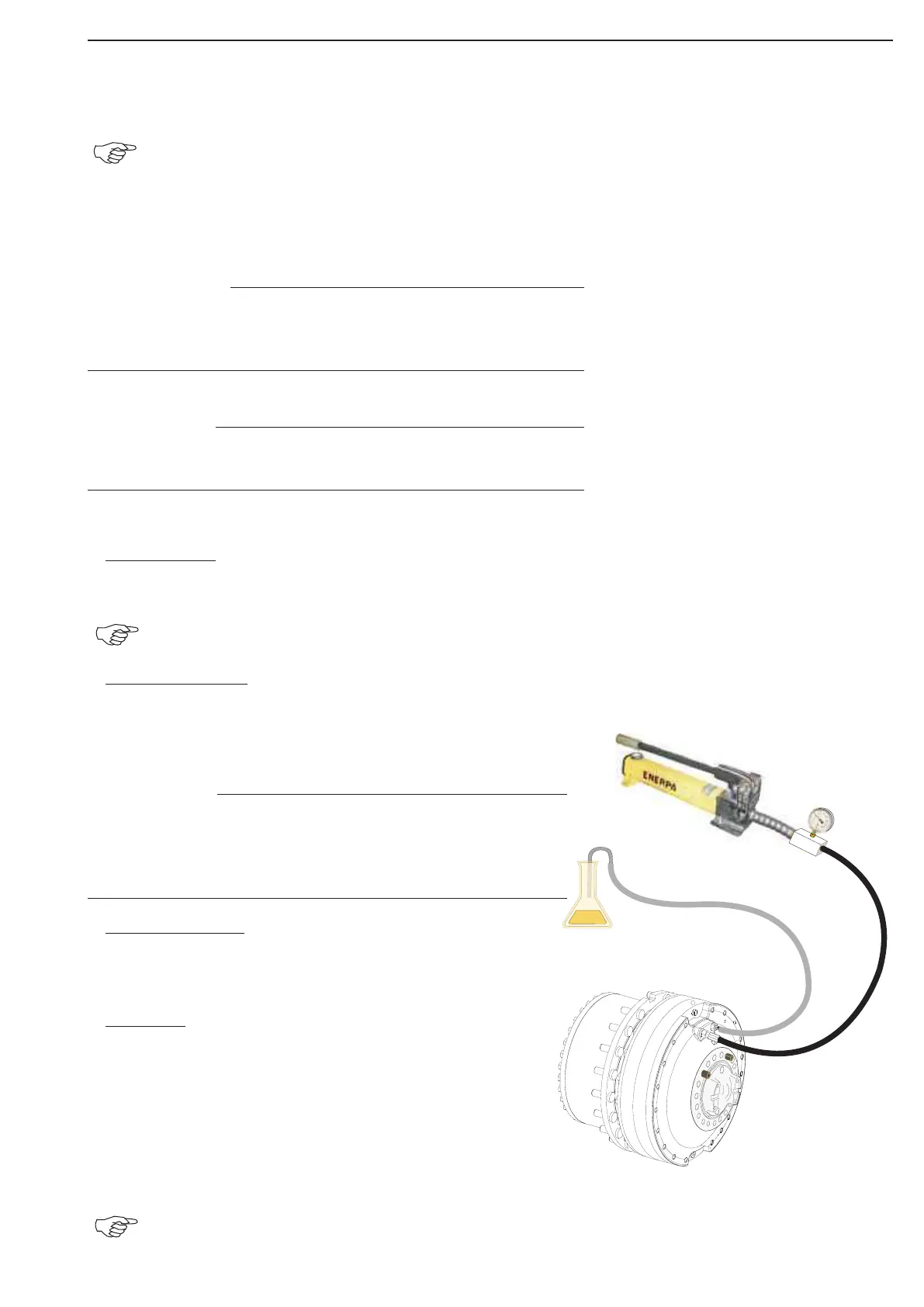

(S) HP-Pump 514661

(S) Mini measuring hub 514670

(S) Bleeding equipment 514659

Prior to putting the axle into operation, fill in oil

acc. to the lubrication instructions!

Leakage test of brake hydraulics

NOTE

The brake piston extends and the cylinder chamber lls up with

oil. The air accumulates in the upper section of the cyl. cham-

ber.

NOTE

The retracting piston presses the air out of the upper section of

the cylinder into the brake line.

NOTE

Figure 121

Loading...

Loading...