SHOP MANUAL

Ch 5 page 58

HYDRAULIC SYSTEM

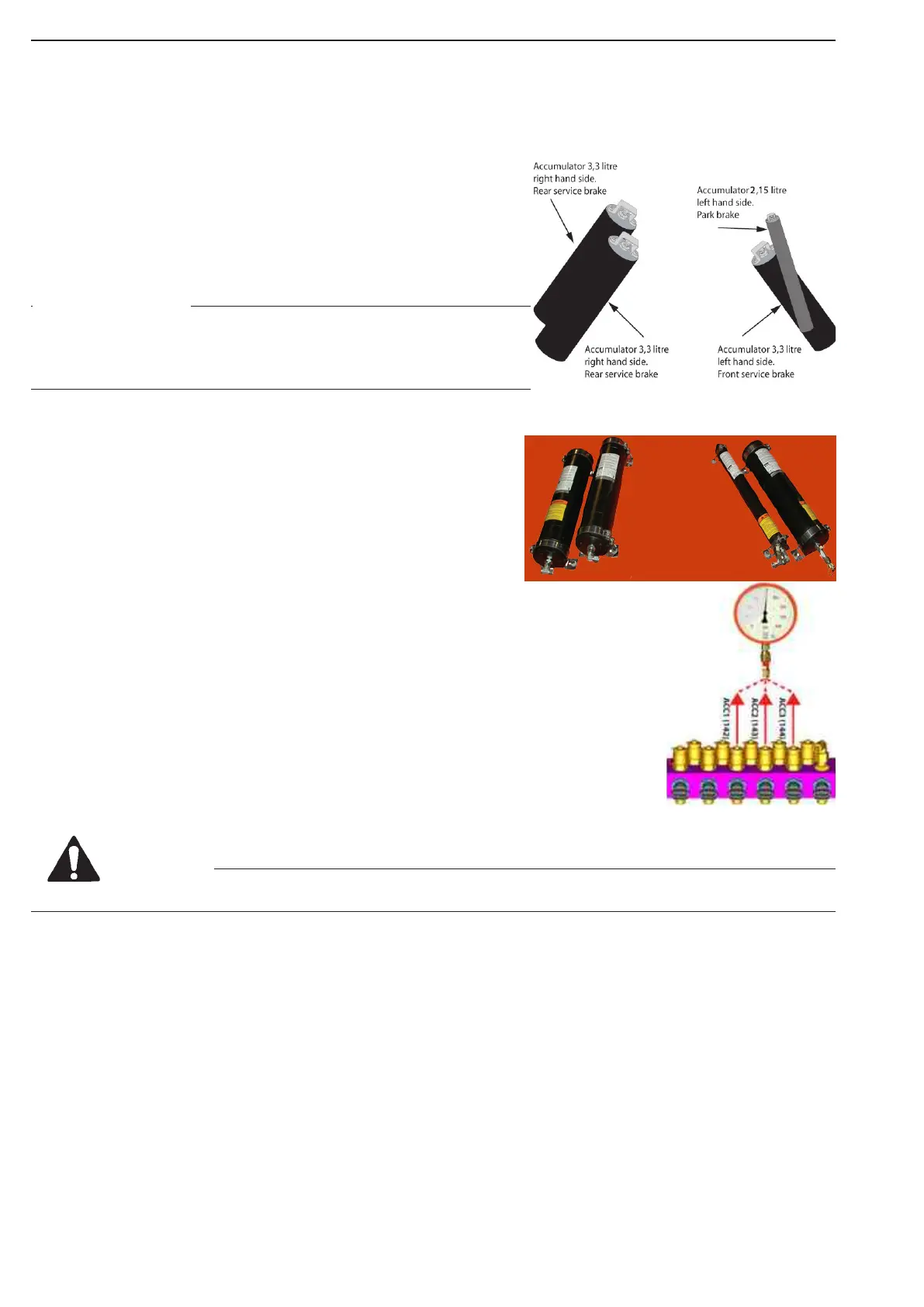

Description of the Accumulators

The 2,15Litre parking brake accumulator is placed on the left side

of the cab front wall along with the 3,3Litre front service brake ac-

cumulator.

The two 3,3Litre rear service brake accumulators are placed on the

right side of the cab front wall.

The accumulators are from DOOSAN factory loaded with Nitrogen

(N

2

)

Pre-Charge

Wet disc brake: Pressure: 58,0 bar

Park brake: Pressure: 112,5 bar:

Read the loading instruction marked on each of the accumulators.

Accumulators

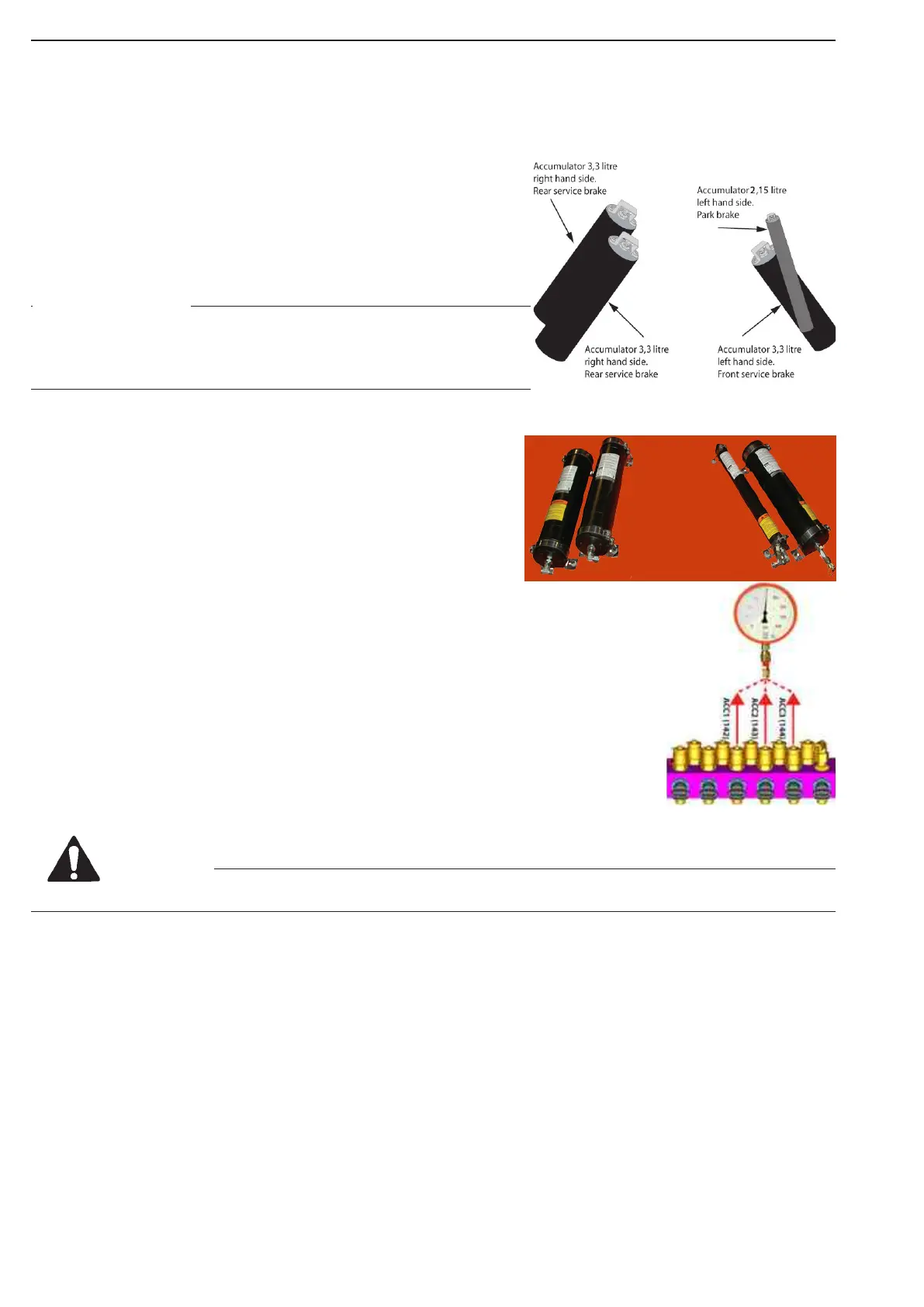

Checking and Adjusting Precharge Pressure

The precharge pressure of the accumulator may

be checked, and nitrogen filled or vented, using the UCA

Universal Charging & Gauging kit. (See view of the kit at next page)

The UCA assembly is screwed onto the accumulator’s gas

valve, allowing the precharge pressure to be checked or reduced.

If the precharge pressure is to be increased, the UCA can be

connected to the nitrogen source with the hose supplied. The UCA

kit is supplied with two pressure gauges, reading 0-25 bar and

0-250 bar; where a different pressure range is required, a

Commercially-available pressure gauge may be used.

Safety

Charging must be carried out by qualified personnel.

Before taking any readings or pressurizing with nitrogen,

the accumulator must be isolated from the hydraulic system

and the fluid side discharged in order to depressurize it.

Use only nitrogen (N2) to pressurize the accumulator.

Danger of Explosion – Never Charge with Oxygen

The types of nitrogen permitted are: type S (99.8% pure); type R (99.99% pure); type U (99.993% pure).

If the pressure of the gas contained in the nitrogen bottle is greater than the maximum permissible operating

pressure of the accumulator, a pressure regulator must be fitted to the nitrogen bottle.

Doosan recommends that the precharge should be checked during the first week following commissioning of

the system.

Thereafter, it should be checked every three months, or at intervals determined by the system builder.

The Effect of Temperature on Precharge Pressure

In order to compensate for the difference in pressure at

ambient and operating temperatures, it is recommended that the precharge pressure po should be adjusted to

reflect the operating temperature of the system, using the correction factor equations and table on page 11.

Warning – Stabilization

The process of charging or discharging an accumulator with nitrogen causes a temperature change which is

transmitted to the surrounding air as the temperature of the accumulator stabilizes.

To allow for the effects of temperature transfer, the accumulator should be allowed to stand for a minimum of 15

minutes before a final reading of the precharge pressure is taken.

NOTE

DANGER

On new models ac-

cumulator test points is

located on the test block

Figure 52

Figure 53

Loading...

Loading...