Engine

SHOP MANUAL

Ch 1 page 163

Alternator 100 A

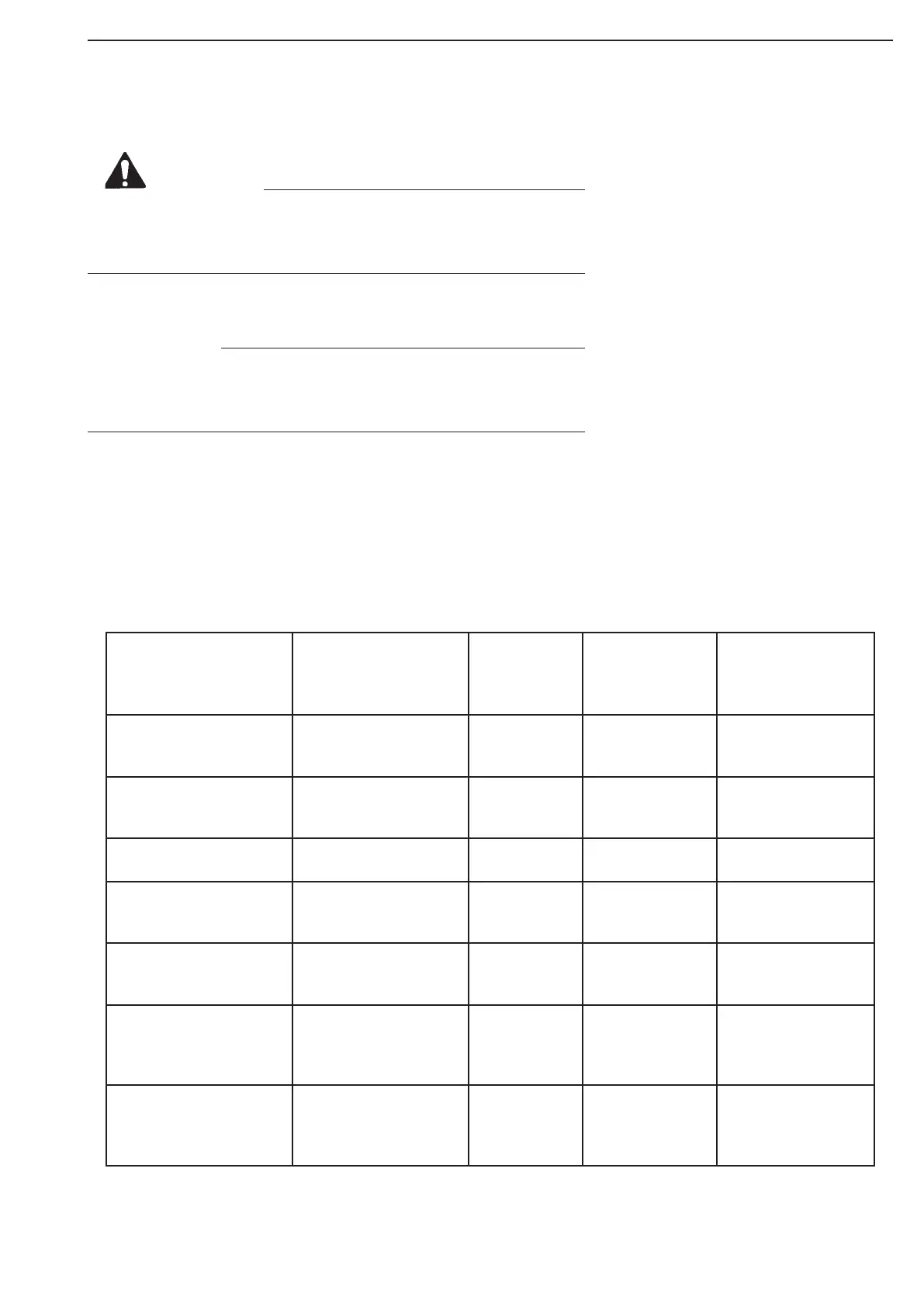

When the engine control unit has generated fault codes for the alternator, the following tests can be carried out.

• Output test

• Control voltage test

• Phase measurement

• Length of brushes

• Slip rings, rotor resistance and overcharging

Test Test values Mea-

sured

values

Acceptable

value

Incorrect

value

1. Output test Bosch 100A:

>40A and 28V

Carry out volt-

age test

Carry out phase

measurement

Control voltage test 28 +/- 1.0V at 20°C Alternator OK Check the brush

length

Phase measurement <250 mV Check the

brush length

Renew alternator

Brush length¹ Bosch 100A:

>1.0 mm

Check slip

rings

Renew alternator

Slip rings¹ The surface should

be smooth and bright

Check the ro-

tor resistance

Renew alternator

Rotor resistance be-

tween the slip rings (at

20°C)¹

Bosch 100A:

8.5 +/-0.5 ohms

Carry out over-

charging test

Renew alternator

Measuring overcharg-

ing between slip rings

and framework¹

> 10 MOhm Renew regula-

tor

Renew alternator

Check

Make sure that you never run an alternator without the batteries

connected! This may cause the rectiers and/or charge regula-

tor to be overloaded and damaged.

To obtain a correct result, the alternator should be kept at a

temperature of 20-25°C. A higher temperature may give a lower

current.

NOTE

CAUTION

Figure 318

Loading...

Loading...