SHOP MANUAL

DRIVE LINE

Ch 3 page 140 Ch 3 page 141

DRIVE LINE

CONTACT PATTERN EXAMPLES OF GLEASON

TOOTH SYSTEM

Field of application:

The contact pattern examples are applicable for all bevel gear sets

in MT and MS axles which have a ratio

between 1.5 < i < 6.

Furthermore, the examples are only valid for ground bevel gear

sets.

(The examples are just partly applicable for lapped contact pat-

terns).

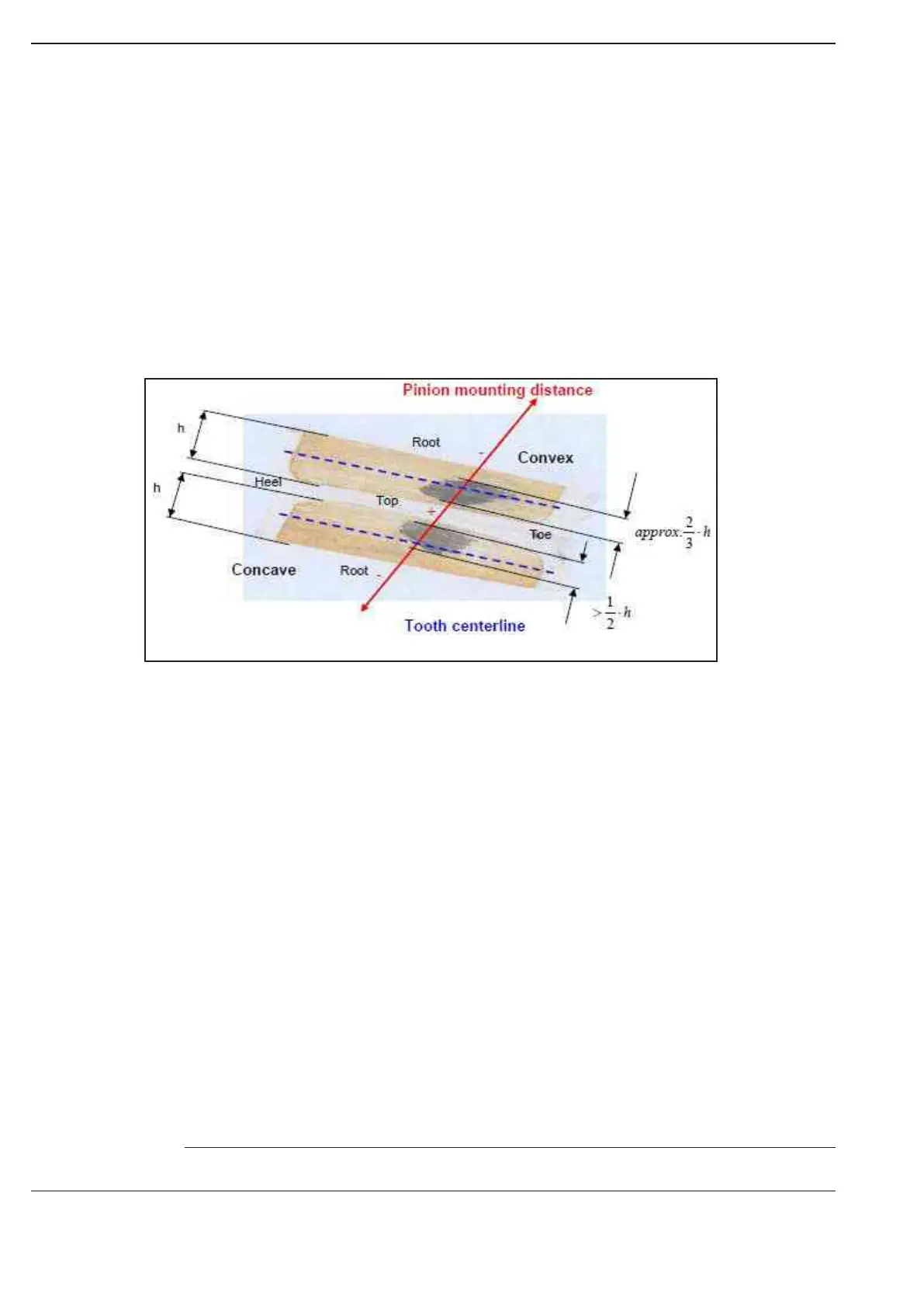

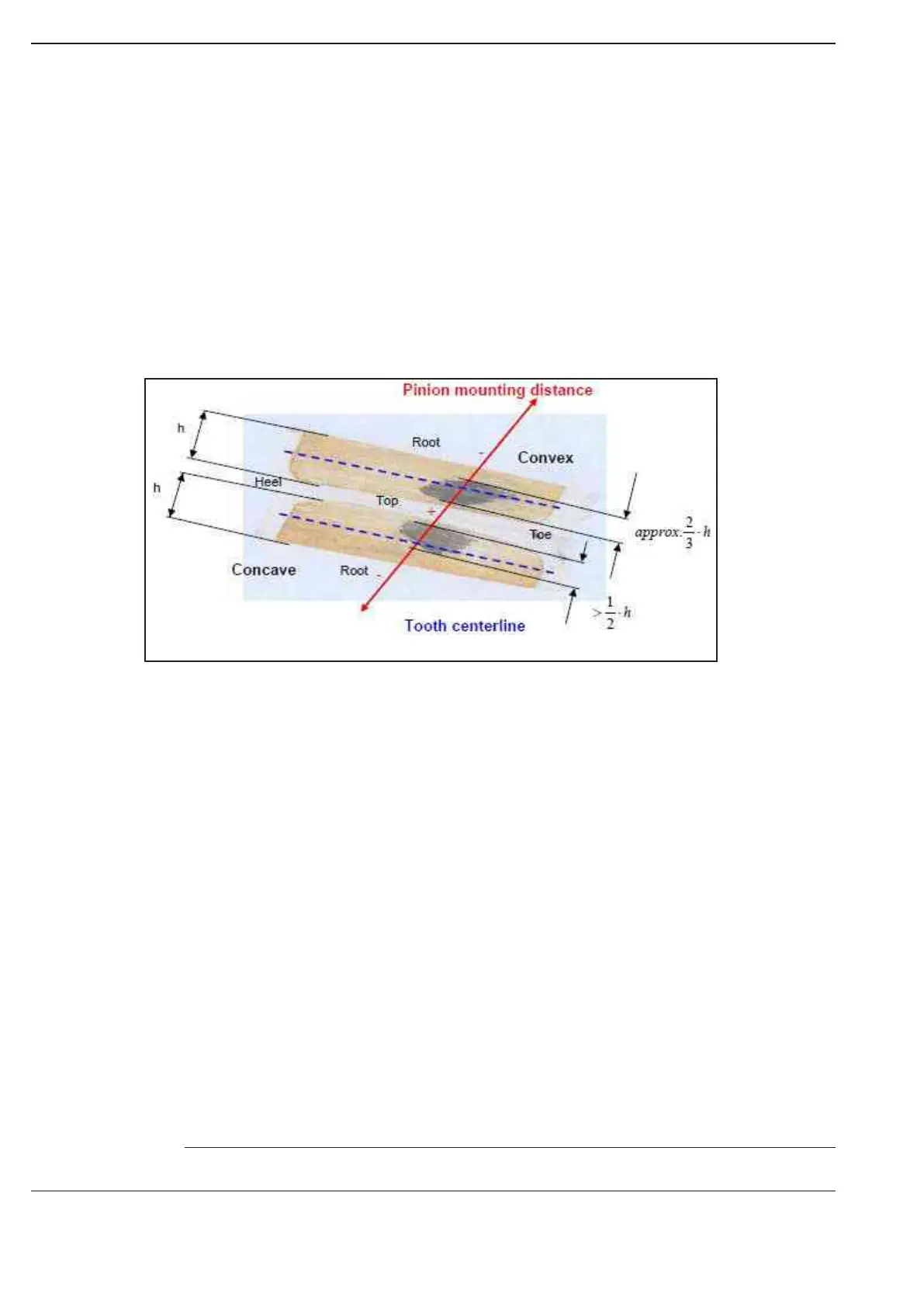

Ideal contact pattern fig. 411

Contact pattern setting:

The contact patterns are viewed on the crown wheel flanks.

The contact pattern must be tangent to the middle of tooth (tooth centerline), otherwise it is too

close to the tooth top or root. Furthermore, the contact pattern should cover at least 50% of the

flank in h-direction (inspection criterion).

General:

By shifting the pinion the contact pattern is moved to the tooth or top.

Pinion mounting distance in + : = reduce pinion shim thickness

Pinion mounting distance in - : = increase pinion shim thickness

Flank glossary:

Convex flank = Drive side

Concave flank = Coast side

Toe = Crown wheel inner side

Heel = Crown wheel outer side

The following pages (141 - 142) describe three different examples of contact patterns!

NOTE

Figure 424

Loading...

Loading...