SHOP MANUAL

Engine

Ch 1 page 252

Compressed air system

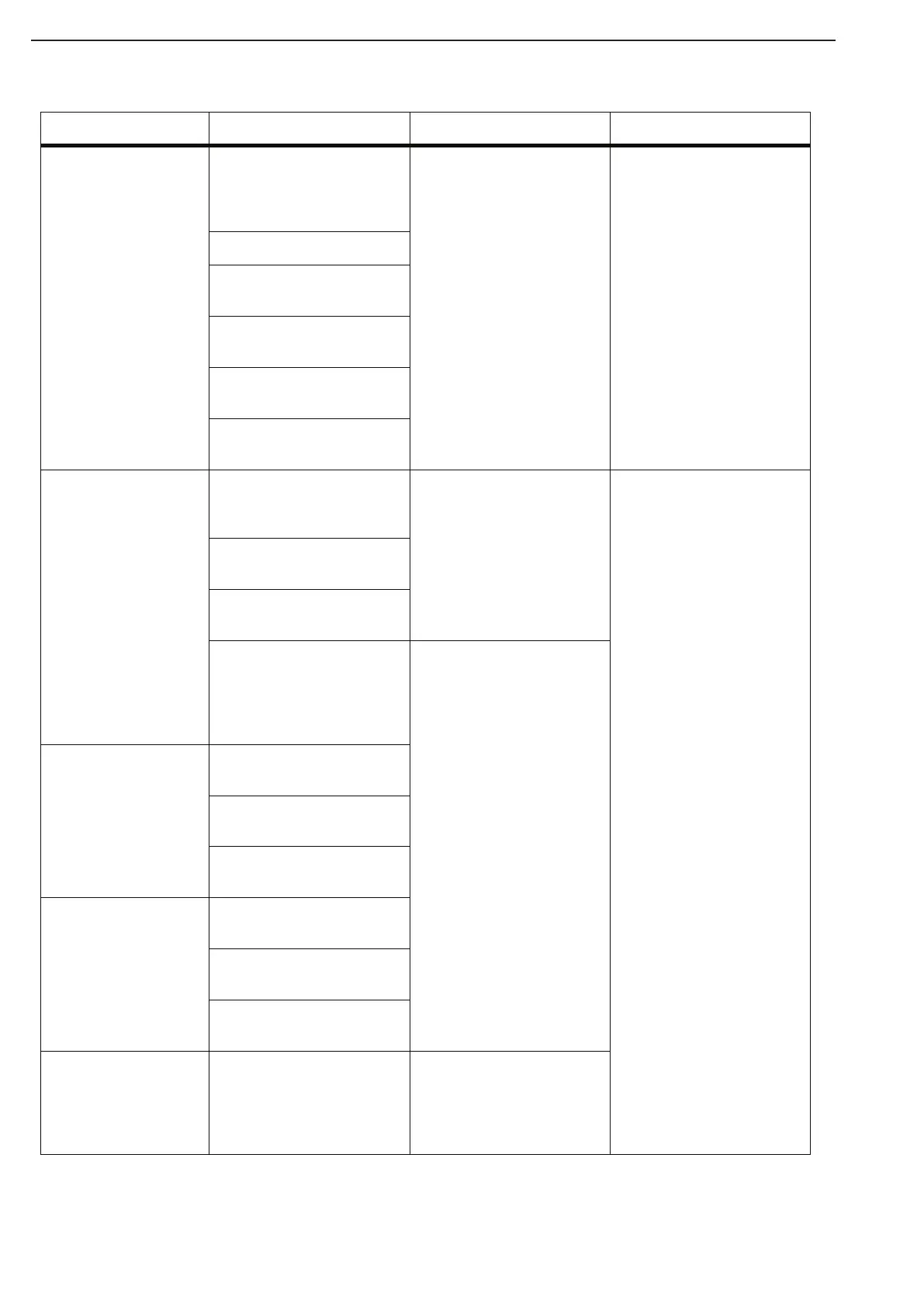

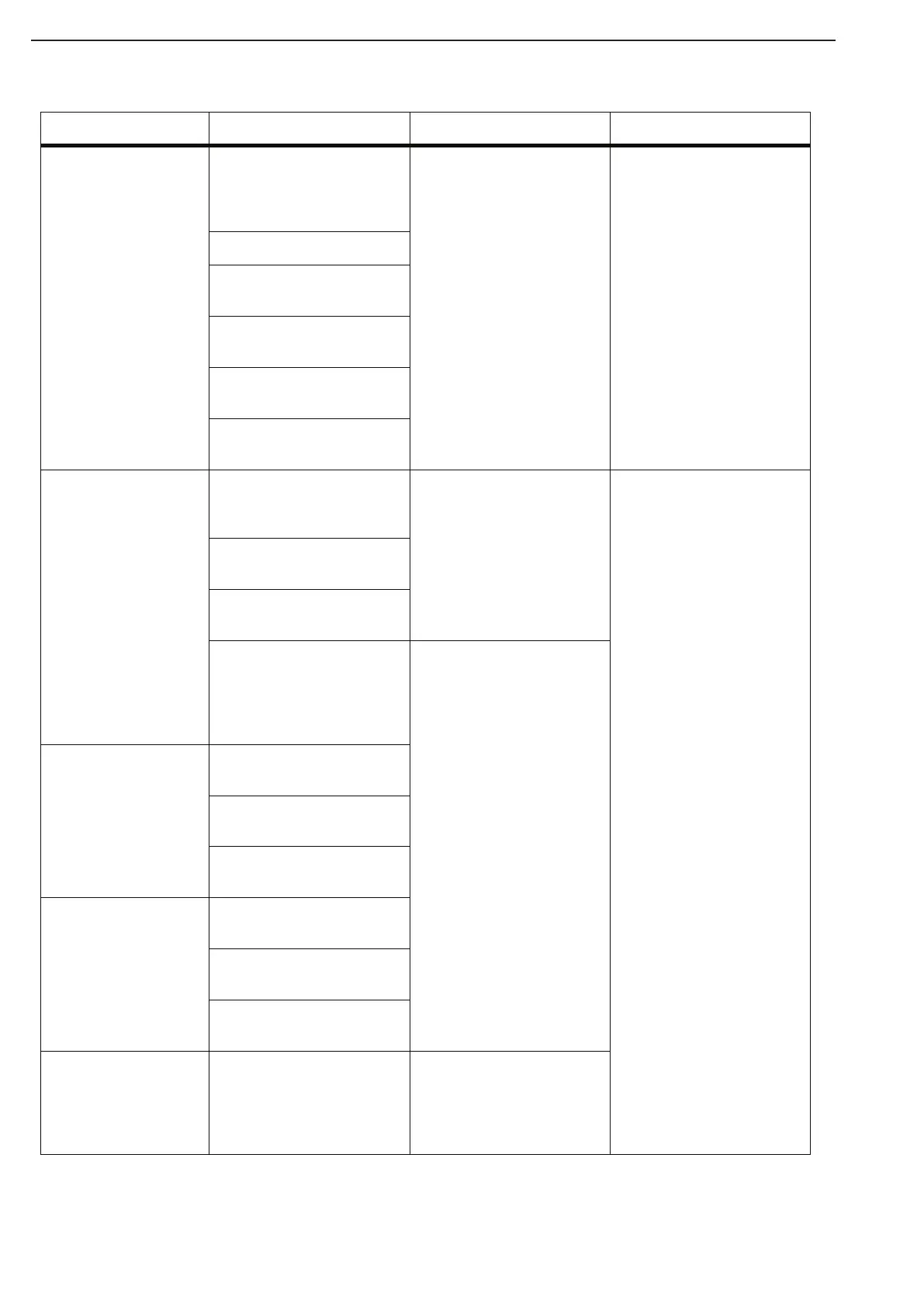

Eect Cause Trouble shooting Action

Compressor does

not maintain su-

cient pressure in the

system

Too much carbon in

compressor cylinder

head or discharge

piping

Empty the compressed

air tank, retain the air in

connected compressed

air components.

Run the engine at

1200 r/min and note the

time it takes for the com-

pressor to discharge:

3 - 3.5 min. for 9/11-

series engines with

90-110 dm

3

tank capac-

ity

2.5 - 3 min. for 14-series

engine with 90-110 dm

3

tank capacity

- If charging time

exceeds specied val-

ues:

- Rectify leakage, if any

- Check/rectify pressure

regulator

- Check/rectify compres-

sor

Exhaust valves leak

Worn pistons and cylin-

ders

Leaking/jammed intake

valves

Defective pressure regu-

lator

Leakage in compressed

air piping

Noise

Too much carbon in

compressor cylinder

head or discharge piping

Check/rectify compres-

so

r as described in the

Workshop Manual

Worn big end/main

bearings

Worn pistons and cylin-

ders

Compressor gear loose

on shaft, see also

“Knocking/noise”,

page “Knocking/noise”

Compressor allows

passage of oil, see

also “High oil con-

sumption”, page

“High oil consump-

tion”

Worn pistons and cylin-

ders

Piston rings tted

wrongly

Overpressure in engine

crankcase.

Compressor does

not discharge

Defective seals on dis-

charge pistons

Discharge mechanism

binding

Defective pressure regu-

lator

Moisture/oil in com-

pressed air system

Air dryer not working

properly

Check operation of air

dryer, change desiccant.

If desiccant is oily, see

“Compressor allows

passage of oil” above

Loading...

Loading...