SHOP MANUAL

SHOP MANUAL

LUBRICATION SYSTEM

Ch 4 Page 14 Ch 4 Page 15

LUBRICATION SYSTEM

Solid additivites in the grease (e.g. Teflon (PFTE) and graphite) can cause blockages in the greasing system in

the long run. Therefore Groeneveld advises against the use of these kinds of grease in the greasing system.

Grease with molybdenum disulphide (MoS

2

) may only be used when the grease is of top quality and contains

no more than 5% MoS

2

.

Maintenance

Regulary checks of the greasing system

Check the following points of the Twin greasing system:

1. The grease level in the reservoir of the pump unit (refill on time);

2. The pump unit for damage and leakage;

3. The operation of the whole greasing system. perform a test cycle for both primary grease lines;

4. The primary and secondary grease lines for damage and leakage;

5. The greasing points, collar of fresh grease should be present at all greasing points;

6. The stored data in the controller-unit of the pump by connecting a diagnosis-unit (PC-GINA).

Bleeding the pump

When the system malfunctions repeatedly after the grease reservoir has been emptied, it is possible that the

pump or the ain-lines have to be bled.

Proceed as follows:

1. Make sure that the grease reservoir is filled to the max;

Check that the system is pressureless, before the system is opened.

2. Remove both lines from the pump;

3. Turn on the ignition;

4. Press the test button on the pump unit for at least 6 seconds (continuous-test cycle);

5. Turn off the ignition as soon as pure grease (without air-pockets) leaves on of the outlets.

When after a few minutes still no grease exits the pump outlet we advise to pump some oil into the

reservoir along the ller-coupling (500cc or 1/8 gallon will be sufcient). This will help to push aside the

air-pockets around the pump piston. The oil can be pumped into the reservoir along grease outlet B, but

than rst the pump need to be stopped by turning off ignition.

6. Re-mount the lines to the pump as soon as grease without air-pockets come from one of the pump utlets;

7. Carry out a single-test cycle twice to check that the greasing system functions correctly;

8. When pressure build up in the system is still not sufficient it is possible that also the grease lines need to be

bled;

9. To make sure that the pump is still in good condition also the grease pressure could be measured with a

manometer, direct at one of the pump outlets. During the pumping phase the pressure should reach 230 to

250 bar and is not allowed to fall below 200 bar during succecive “pressure retaining phase”.

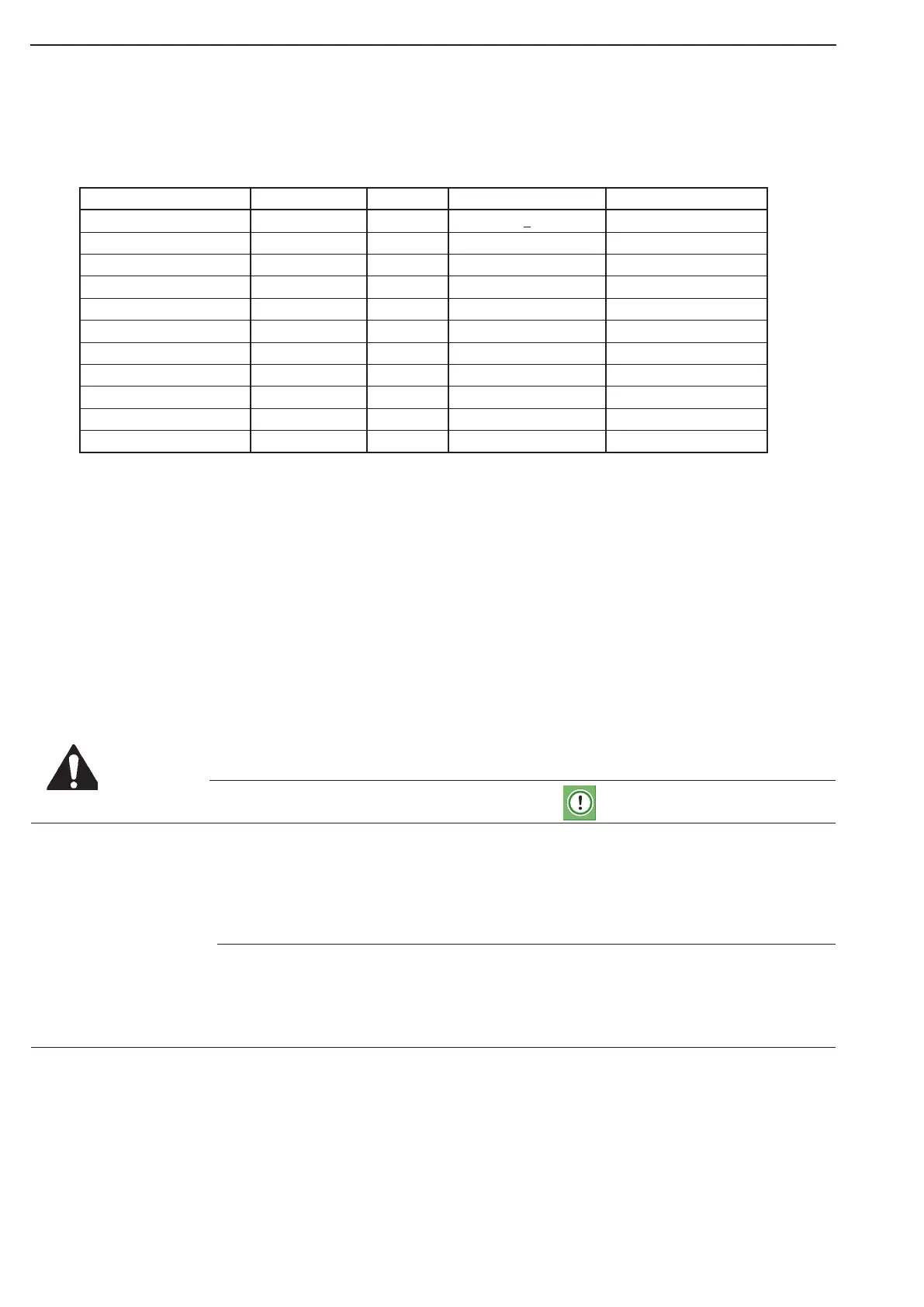

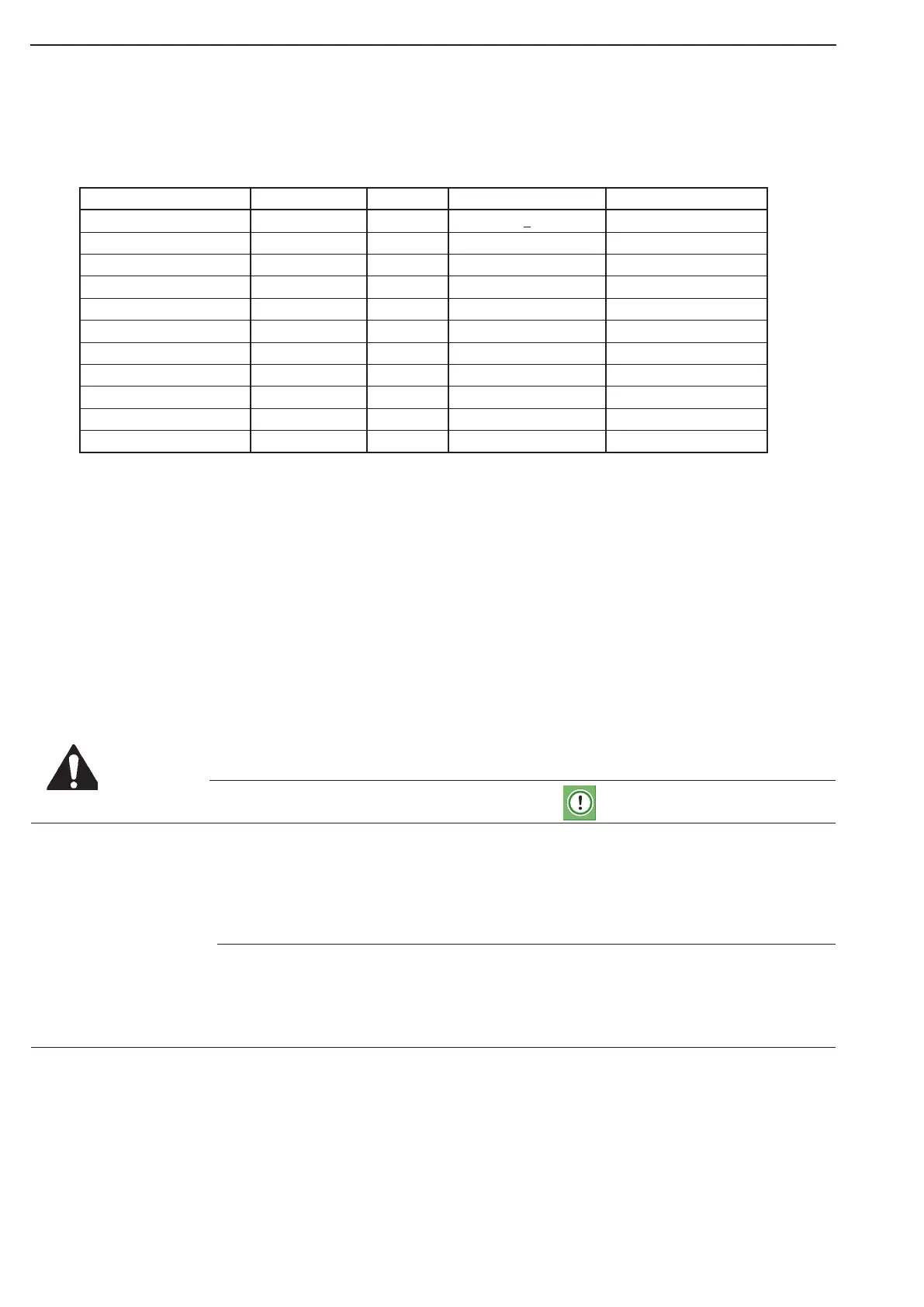

Description ASTM test Method Min/Max Specification Remarks

NLGI Grade Std

2 -10 to +40 Degree Celsius

Thickener type Min Lithium Complex

Solid Additives, Moly Max 3 % No Graphite

Oxidation Stability @ 100hrs D942 Max 0,3 bar

Water washout @ 79°C Max 4 %

Dropping piont D1264 Min 230°C

Rust protection D1743 Pass

Copper corrosion D4048 Max 1b

Base oil viscosity D445 Min 600 cSt @ 40°C

Four ball (EP) weld point D2596 Min 400 kg

Four ball wear D2266 Max 0,6mm 1hr @ 75°C/1200rpm/40kg

WARNING

NOTE

Loading...

Loading...