SHOP MANUAL

DRIVE LINE

Ch 3 page 72 Ch 3 page 73

DRIVE LINE

General function

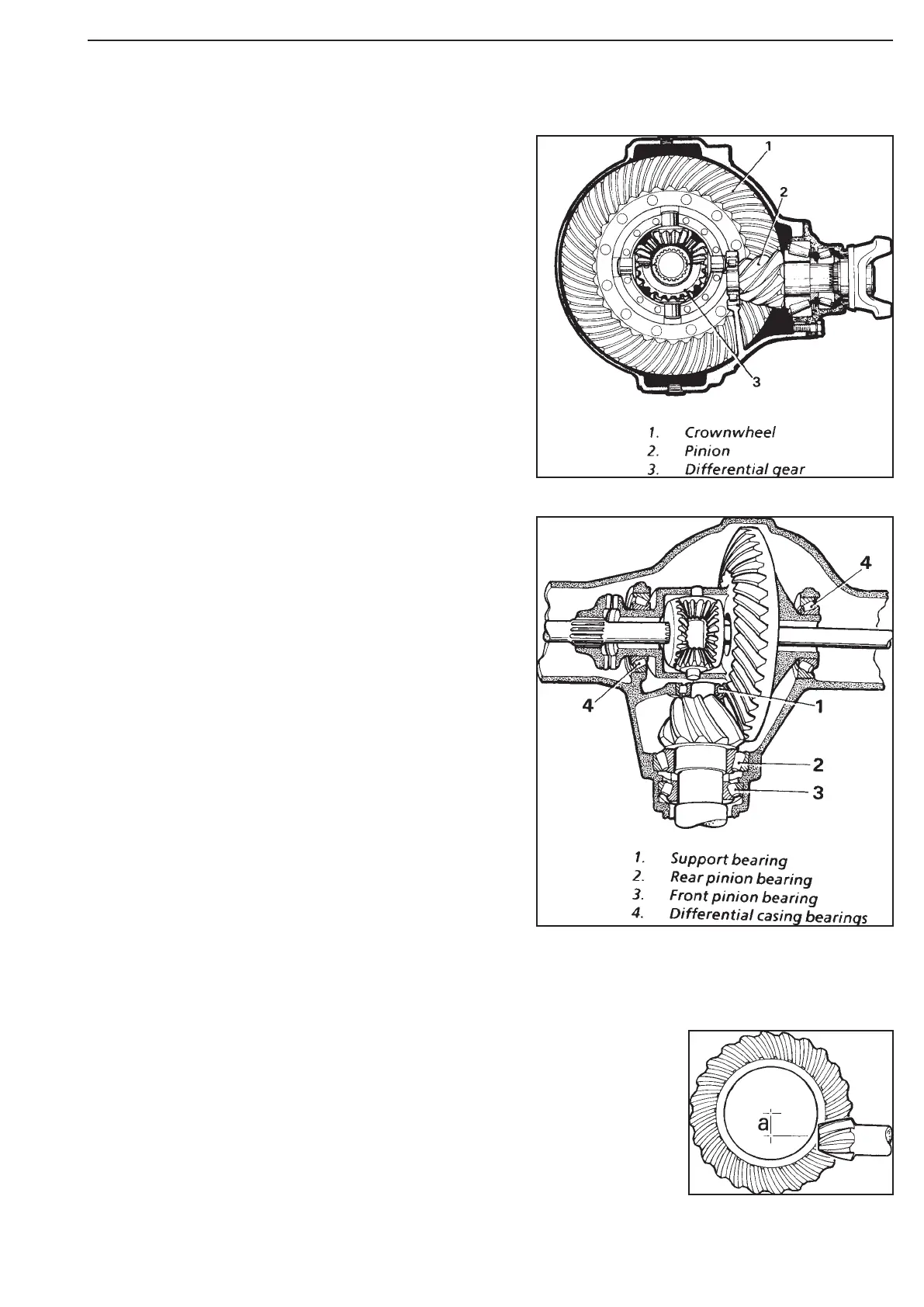

With a hypoid crownwheel and pinion arrangment the

pinion centre is below the centre of the crowwheel, which

provides the teeth with increased strength by

extended sliding mesh and more tooth overlap.

Distance “a” is known as offset

Under heavy load the gearwheel set is exposed to

forces which both tend to push the pinion forward

(front diff.) / backward (rear diff.), as well as pressing

the crownwheel and pinion apart.

To prevent this, the pinion runs in robust roller

bearings.

The rear diff. has a support bearing which is cylindrical

and seated in the gear housing inside the crownwheel

circumference.

The other two bearings are taper roller bearings and

absorb the axial and radial forces in the pinion.

The crownwheel is attached to the differential casing,

which runs in two robust taper roller bearings in the

differential housing.

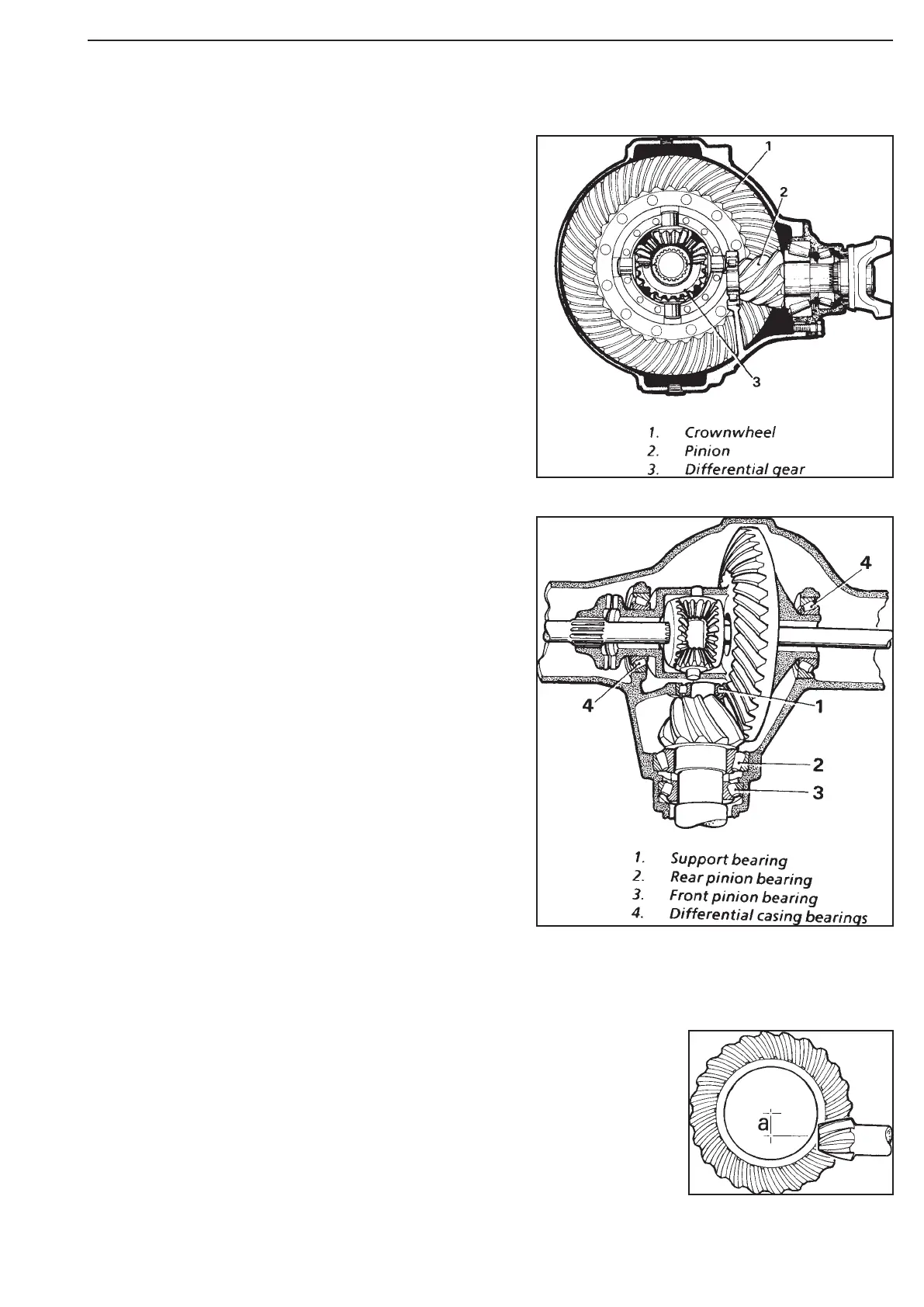

The differentials transmit the torque of the transmission

output propeller shafts to the wheels.

The differential contains one crownwheel and one pinion,

as well as a differential gear.

The teeth of the crownwheel and pinion are cut in

a special way to provide proper mesh and high strength.

As heavy torque has to be transmitted, the fit between

crown wheel and pinion has to be accurate and therefore

the parts are lapped together as a pair in manufacturing.

When changing crownwheel or pinion, both parts have to

be changed.

Figure 190

Figure 189

Figure 191

Loading...

Loading...