SHOP MANUAL

DRIVE LINE

Ch 3 page 74 Ch 3 page 75

DRIVE LINE

Although the wheels have different distances to roll when negotiat-

ing bend and thereby different rotation speed, exactly the same

drive torque has to be transmitted to both sides.

This torque distribution takes place in the differential gear.

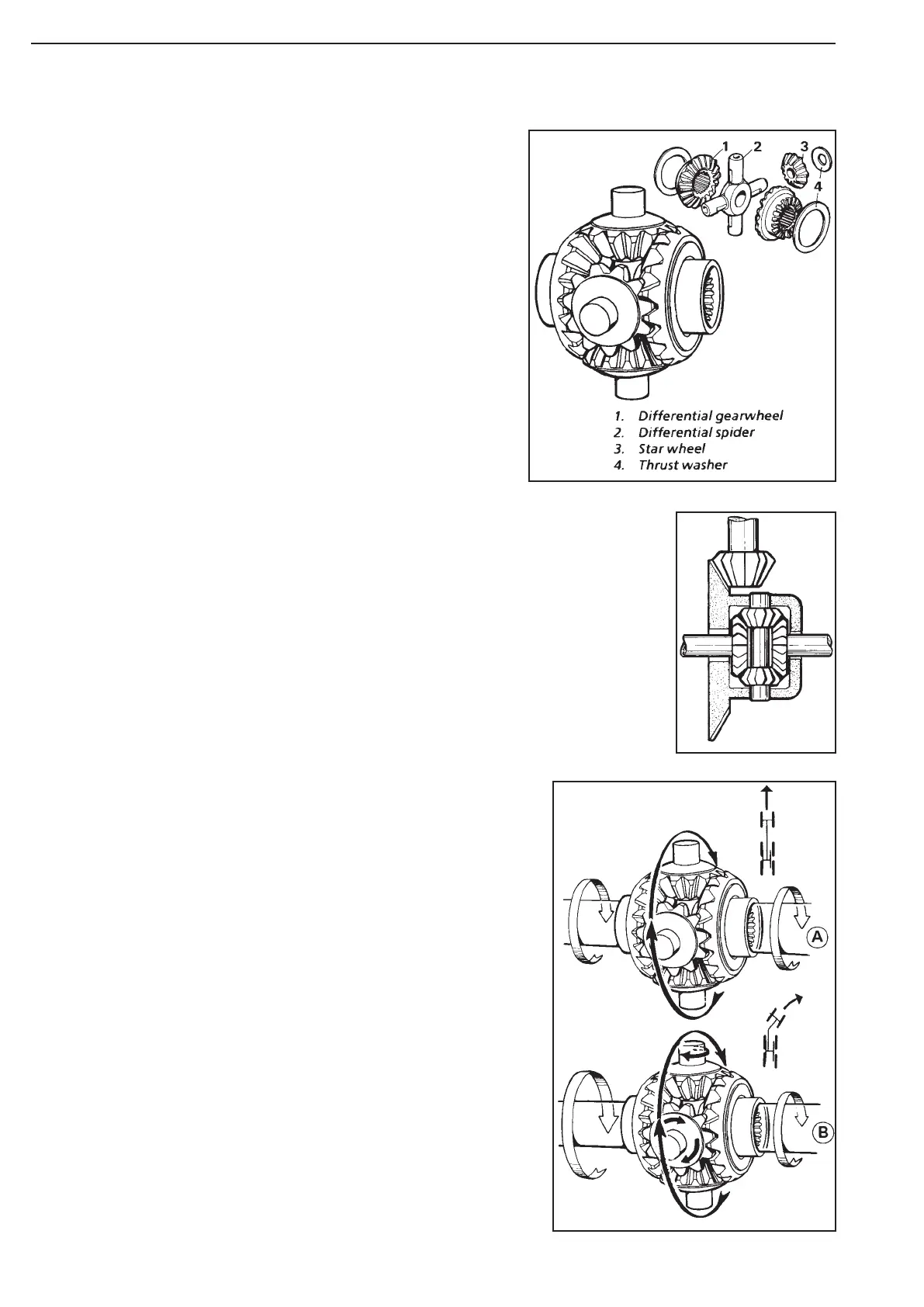

The differential gear consists of four taper gear wheels, star

wheels, that run on a differential spider.

The star wheels are in constant mesh with two opposed differential

gear wheels, each attached to a half shaft.

The differential gear sits in the differential casing to which the

crown wheel is attached.

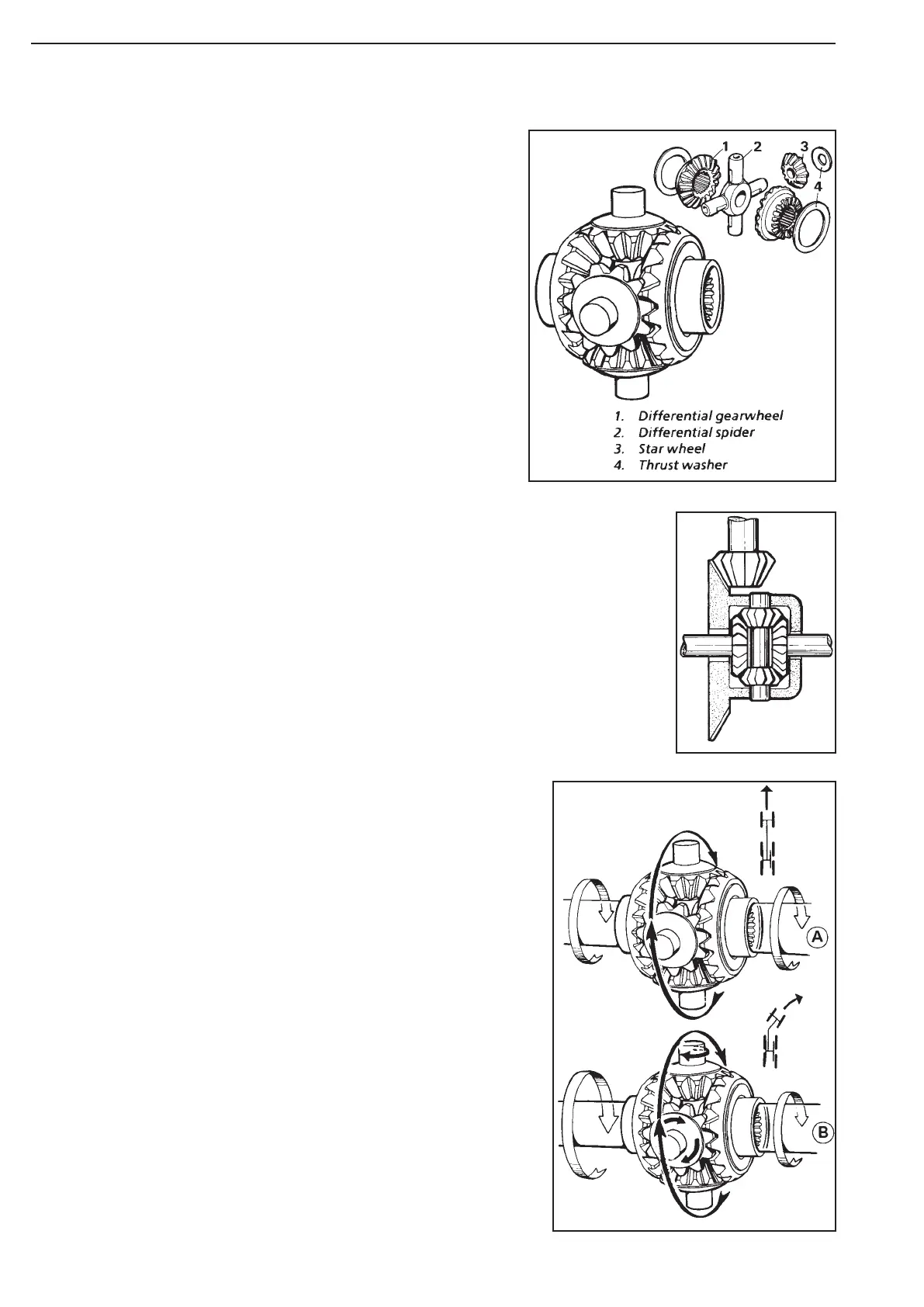

When the truck travels straight ahead and the rotation speed of the

drive wheels is the same, the star wheels on the differential spider

do not turn, and only function as a driver between crownwheel and

half shafts.

When the dump truck travels round a bend, the inner drive wheels

will roll a shorter distance than the outer ones. Because of the

drive wheels then having different rotation speeds, this also ap-

plies to the differential gear wheels on the half shafts. The star

wheels will then turn.

Because of the compound speed of the drive wheels being con-

stant, the outer drive wheel will turn much faster in relation to the

crown wheel, as the inner drive wheel will turn slower.

In extreme cases, when one drive wheel side is stationary and

the other one spins, the spinning wheels turns twice as fast as the

crown wheel.

If a drive wheel side does not have sufficient grip and starts spin-

ning, the dump truck comes to standstill. The grip of the spinning

wheels determine the amount of torque.

This torque becomes decisive in regards to the drive power of both

sides because the differential gear will always distribut the torque

equally to both sides.

Figure 194

Figure 193

Figure 192

Loading...

Loading...