SHOP MANUAL

Engine

Ch 1 page 122

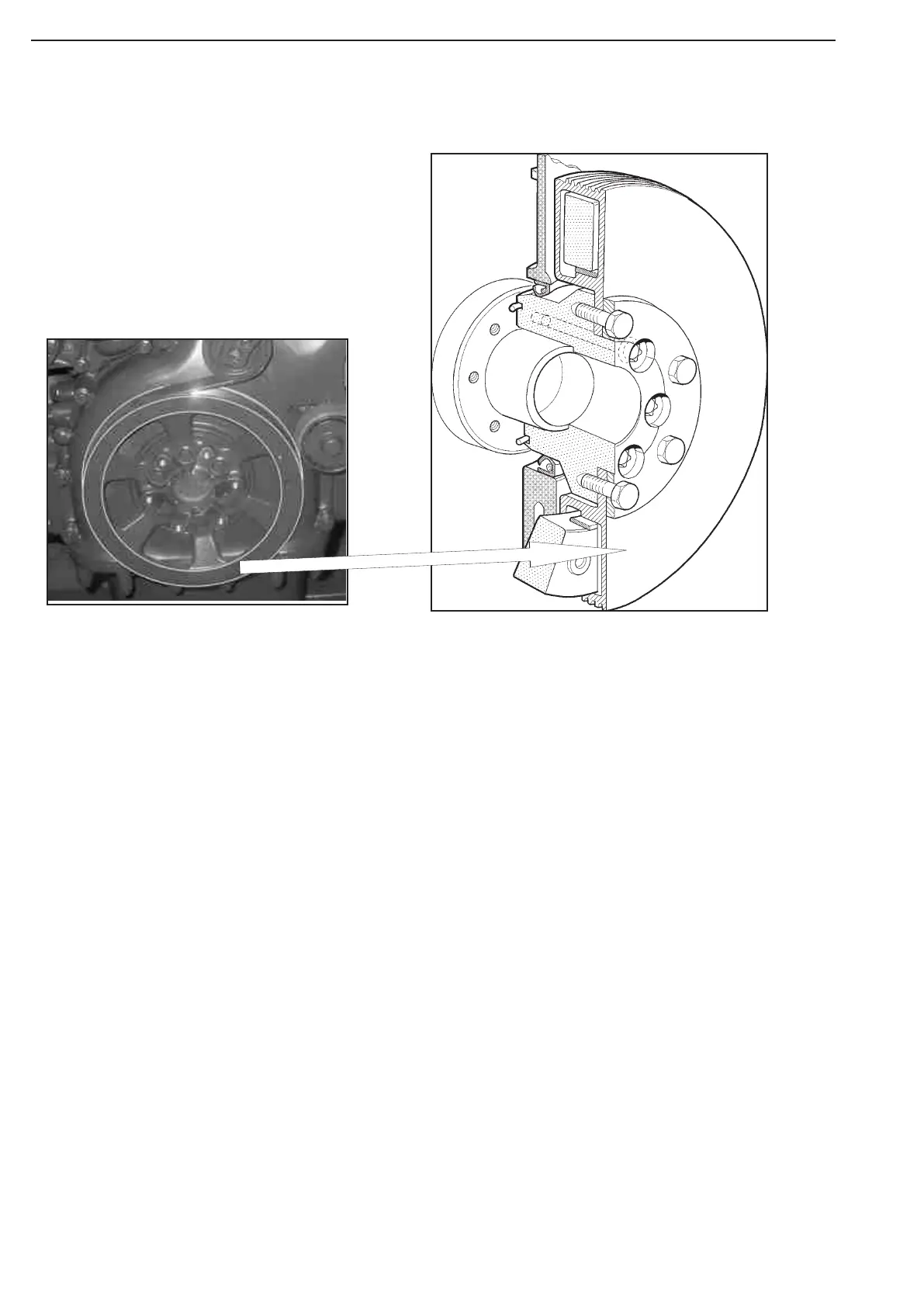

Crankshaft damper

The power impulses from the connecting rods give rise to torsional oscillation in the crankshaft. These oscillations

are severest at certain engine speeds which vary with the design of the engine, how it is loaded, etc.

Torsional oscillation is characterised as follows:

The flywheel (at the “rear” end of the crankshaft) rotates at an almost constant speed throughout each revolution

of the crankshaft. Relative to the flywheel, the rotational speed of the front end of the crankshaft will increase and

decrease several times during each revolution.

To reduce the amplitude of the oscillation, a crankshaft damper is attached to the front end of the crankshaft.

A ring of steel is incorporated in the circular and completely enclosed housing of the crankshaft damper. The

housing is bolted onto the crankshaft.

There is a heavy oil between the housing and ring which damps the relative movement between the two. The

oscillation at the front of the crankshaft is damped by the ring striving to rotate with even speed.

The crankshaft damper has numerous belt grooves for a “Multigroove V-belt”.

Figure 235

Figure 236

Loading...

Loading...