SHOP MANUAL

DRIVE LINE

Ch 3 page 200 Ch 3 page 201

DRIVE LINE

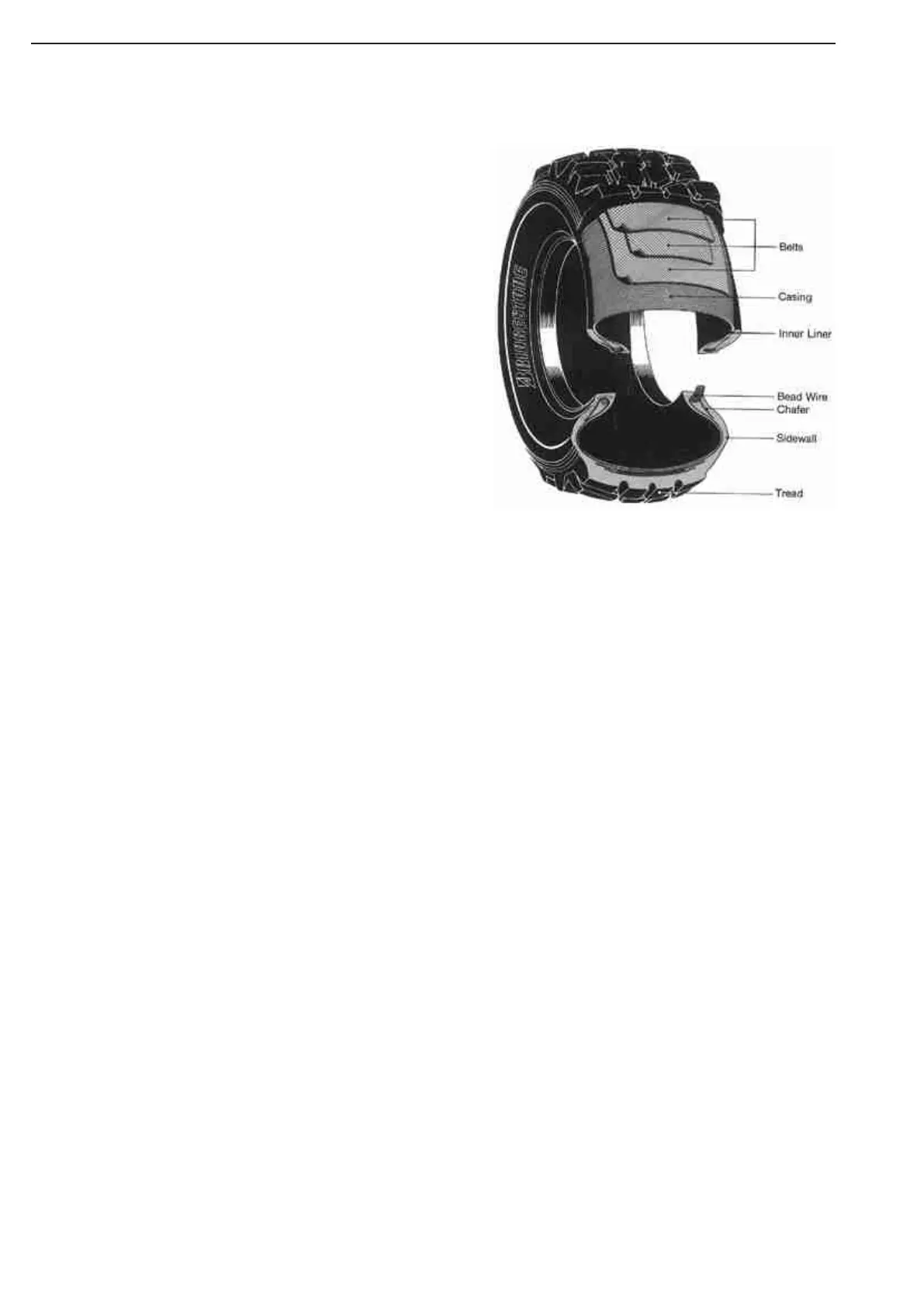

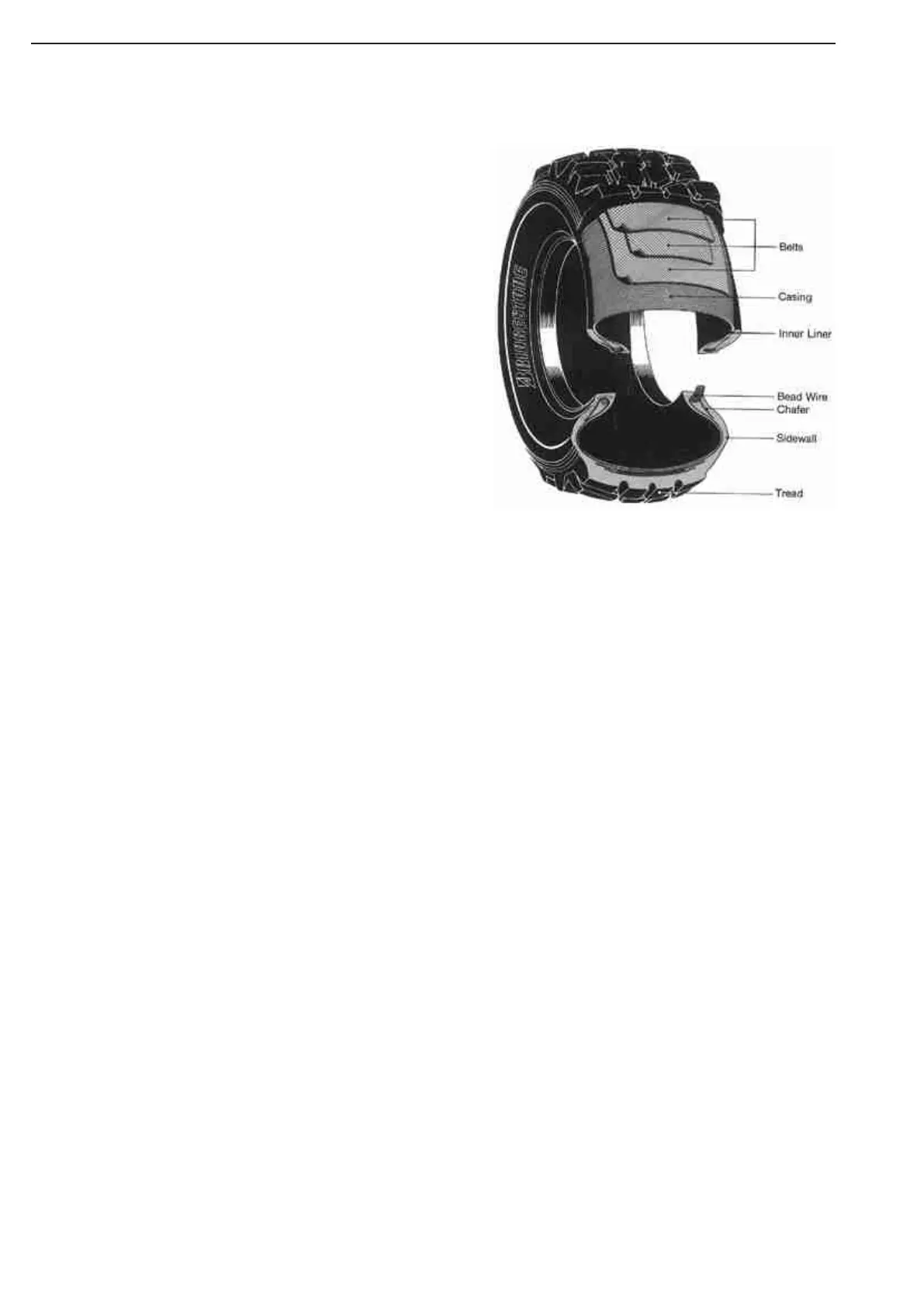

Tyres

A tyre consists of four primary components;

casing plies, beads, belts and tread. All four

components are primarily responsible for the

fundamentar characteristics of the tyre.

BELTS.

Extra layers of rubber-coated cord are placed between the outer plies and the tread, in order to protect the

plies, preventing cuts from reaching the ply cords and absorbing shock.

CASING.

A tyre is composed of several layers of plies, which are coated on both sides with a rubber compound. These

layers maintain the inflation pressure of the tire in supporting the load. Composed of high-tensile nylon cords,

it has greater resistance to heat, shock and cutting, adding to the durability of the tyre. The term “Ply Rating”,

according to the TRA, is defined as follows: “A given tyre with its maximum recommended load when used in

a specific type of service. It is an index of tyre strength and does not necessarily represent the number of cord

plies in the tyre.

INNER LINER.

The inner liner is a rubber layer covering the inside of a tyre from bead to bead, and corresponds to the tube

of an ordinary tyre using a tube. It keeps the inflation pressure constant, while reducing weight and simplifying

maintenance by eliminating the tube.

BEAD.

All plies are tied into bundles of steel wire. The beads are the parts which fit the tyre perfectly on the rim, pre-

venting the tire from slipping out of the rim contour while the vehicle is in motion.

SIDEWALLS.

Sidewalls are covers made of a flexible rubber compound which protect the sides of the tyre. They are de-

signed, under ordinary usage, to cushion the plies from shock and cutting, and to flex and bend without crack-

ing.

TREAD.

The tread compounds used in Bridgestone tyres are highly resistant to abrasion and cutting. Different tread

patterns are employed according to the particular usage of the tyre. This patterns feature excellent traction,

longer serviceability and higher resistance to cutting.

Figure 584

Loading...

Loading...